Supply chain control towers provide centralized visibility and real-time monitoring across the entire supply chain network, enabling proactive issue resolution and enhanced decision-making. Order Management Systems (OMS) focus on streamlining order processing, inventory allocation, and fulfillment across multiple sales channels. Explore how integrating supply chain control towers with OMS can optimize logistics operations and improve customer satisfaction.

Why it is important

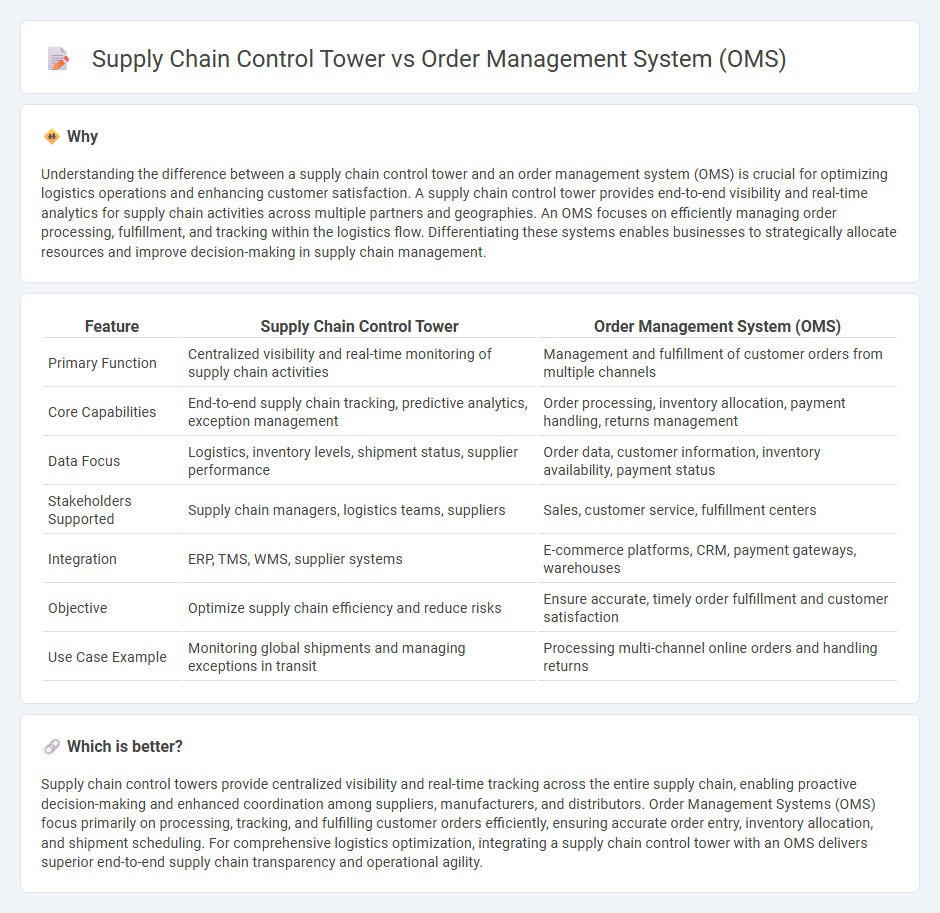

Understanding the difference between a supply chain control tower and an order management system (OMS) is crucial for optimizing logistics operations and enhancing customer satisfaction. A supply chain control tower provides end-to-end visibility and real-time analytics for supply chain activities across multiple partners and geographies. An OMS focuses on efficiently managing order processing, fulfillment, and tracking within the logistics flow. Differentiating these systems enables businesses to strategically allocate resources and improve decision-making in supply chain management.

Comparison Table

| Feature | Supply Chain Control Tower | Order Management System (OMS) |

|---|---|---|

| Primary Function | Centralized visibility and real-time monitoring of supply chain activities | Management and fulfillment of customer orders from multiple channels |

| Core Capabilities | End-to-end supply chain tracking, predictive analytics, exception management | Order processing, inventory allocation, payment handling, returns management |

| Data Focus | Logistics, inventory levels, shipment status, supplier performance | Order data, customer information, inventory availability, payment status |

| Stakeholders Supported | Supply chain managers, logistics teams, suppliers | Sales, customer service, fulfillment centers |

| Integration | ERP, TMS, WMS, supplier systems | E-commerce platforms, CRM, payment gateways, warehouses |

| Objective | Optimize supply chain efficiency and reduce risks | Ensure accurate, timely order fulfillment and customer satisfaction |

| Use Case Example | Monitoring global shipments and managing exceptions in transit | Processing multi-channel online orders and handling returns |

Which is better?

Supply chain control towers provide centralized visibility and real-time tracking across the entire supply chain, enabling proactive decision-making and enhanced coordination among suppliers, manufacturers, and distributors. Order Management Systems (OMS) focus primarily on processing, tracking, and fulfilling customer orders efficiently, ensuring accurate order entry, inventory allocation, and shipment scheduling. For comprehensive logistics optimization, integrating a supply chain control tower with an OMS delivers superior end-to-end supply chain transparency and operational agility.

Connection

The supply chain control tower and order management system (OMS) are interconnected through real-time data integration that enhances end-to-end visibility and operational efficiency. The control tower provides centralized monitoring and analytics, enabling proactive decision-making, while the OMS manages order processing, inventory, and fulfillment workflows. Together, they streamline logistics operations by synchronizing demand forecasting, inventory levels, and delivery schedules to optimize supply chain performance.

Key Terms

**Order Management System (OMS):**

Order Management System (OMS) streamlines order processing by automating order entry, tracking, and fulfillment, enhancing accuracy and efficiency across sales channels. It integrates inventory management, payment processing, and customer communication to optimize order lifecycle management and reduce errors. Explore how OMS can revolutionize your supply chain strategy and boost operational performance.

Order Processing

An Order Management System (OMS) streamlines order processing by automating order entry, inventory allocation, and fulfillment tracking to enhance accuracy and speed. A Supply Chain Control Tower provides a broader, real-time visibility platform that monitors end-to-end supply chain activities, enabling proactive decision-making but relies on OMS data for detailed order execution. Explore how integrating OMS with supply chain control towers can optimize order processing and drive supply chain efficiency.

Inventory Allocation

An Order Management System (OMS) streamlines inventory allocation by efficiently processing customer orders and updating stock levels in real-time to prevent overselling and optimize fulfillment workflows. In contrast, a Supply Chain Control Tower provides a holistic view of inventory across multiple locations, enabling proactive decision-making for inventory rebalancing and demand forecasting to reduce stockouts and excess inventory. Explore in-depth insights to understand how these systems complement each other for enhanced inventory allocation strategies.

Source and External Links

Order Management Systems Defined: What Is an OMS? - An OMS supports all stages of a sales process from order creation through delivery, providing visibility into inventory, managing order fulfillment, shipment confirmations, payments, and returns.

What is Order Management? - An OMS digitally manages the entire order lifecycle, tracking order entry, inventory, fulfillment, and after-sales service to offer real-time visibility and streamline complex omnichannel processes.

Order management system - An OMS is a software system used across industries for order entry and processing, encompassing modules like product info, inventory management, order processing, customer service, and financials to automate and coordinate order workflows.

dowidth.com

dowidth.com