Milk run delivery streamlines supply chain efficiency by consolidating multiple supplier shipments into a single transportation route, reducing transportation costs and improving inventory management through frequent and reliable pickups. Hub-and-spoke distribution centralizes goods at a main hub before dispatching them to various spoke locations, optimizing distribution by leveraging economies of scale and enhancing route planning. Explore the key differences and strategic benefits of milk run delivery versus hub-and-spoke distribution to optimize your logistics operations.

Why it is important

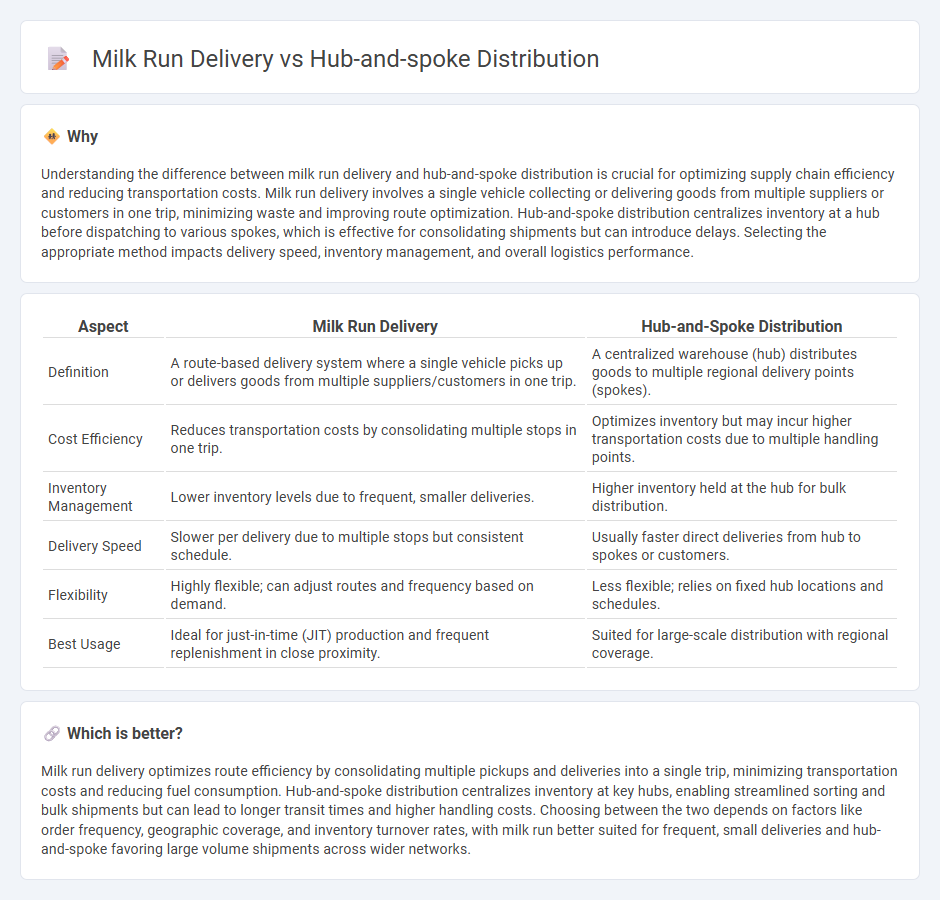

Understanding the difference between milk run delivery and hub-and-spoke distribution is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run delivery involves a single vehicle collecting or delivering goods from multiple suppliers or customers in one trip, minimizing waste and improving route optimization. Hub-and-spoke distribution centralizes inventory at a hub before dispatching to various spokes, which is effective for consolidating shipments but can introduce delays. Selecting the appropriate method impacts delivery speed, inventory management, and overall logistics performance.

Comparison Table

| Aspect | Milk Run Delivery | Hub-and-Spoke Distribution |

|---|---|---|

| Definition | A route-based delivery system where a single vehicle picks up or delivers goods from multiple suppliers/customers in one trip. | A centralized warehouse (hub) distributes goods to multiple regional delivery points (spokes). |

| Cost Efficiency | Reduces transportation costs by consolidating multiple stops in one trip. | Optimizes inventory but may incur higher transportation costs due to multiple handling points. |

| Inventory Management | Lower inventory levels due to frequent, smaller deliveries. | Higher inventory held at the hub for bulk distribution. |

| Delivery Speed | Slower per delivery due to multiple stops but consistent schedule. | Usually faster direct deliveries from hub to spokes or customers. |

| Flexibility | Highly flexible; can adjust routes and frequency based on demand. | Less flexible; relies on fixed hub locations and schedules. |

| Best Usage | Ideal for just-in-time (JIT) production and frequent replenishment in close proximity. | Suited for large-scale distribution with regional coverage. |

Which is better?

Milk run delivery optimizes route efficiency by consolidating multiple pickups and deliveries into a single trip, minimizing transportation costs and reducing fuel consumption. Hub-and-spoke distribution centralizes inventory at key hubs, enabling streamlined sorting and bulk shipments but can lead to longer transit times and higher handling costs. Choosing between the two depends on factors like order frequency, geographic coverage, and inventory turnover rates, with milk run better suited for frequent, small deliveries and hub-and-spoke favoring large volume shipments across wider networks.

Connection

Milk run delivery optimizes logistics by enabling frequent, consolidated pickups and drop-offs along predetermined routes, reducing transportation costs and improving efficiency. Hub-and-spoke distribution centralizes inventory at a central hub, from which goods are dispatched to various spokes or destinations, allowing for streamlined routing and load consolidation. Integrating milk run delivery within a hub-and-spoke system further enhances supply chain responsiveness by ensuring timely replenishment and minimizing empty return trips.

Key Terms

Centralized hub

The hub-and-spoke distribution model centralizes inventory and sorting processes at a single hub, optimizing route efficiency by sending consolidated shipments to numerous spokes or distribution points. This approach reduces transportation costs and enhances control over inventory management by leveraging a centralized hub to streamline delivery schedules and reduce lead times. Explore the benefits and operational details of centralized hub logistics to improve distribution strategies.

Route optimization

Hub-and-spoke distribution centralizes inventory at a main warehouse, allowing consolidation of shipments which can reduce overall transportation costs but may increase delivery times due to routing through the hub. Milk run delivery optimizes routes by creating regular, circular trips that collect and deliver goods efficiently to multiple locations, minimizing vehicle capacity waste and distance traveled. Explore more on how route optimization enhances supply chain efficiency with these delivery models.

Consolidated shipments

Hub-and-spoke distribution centralizes consolidated shipments through a main hub, improving load optimization and reducing overall transportation costs by combining goods from multiple origins. Milk run delivery enhances consolidation by following fixed routes that repeatedly pick up shipments from multiple suppliers, minimizing inventory buildup and transportation waste. Explore detailed strategies to optimize your supply chain with consolidated shipment methods for efficient logistics.

Source and External Links

Hub and Spoke Model In Logistics And Its Importance - NimbusPost - The hub-and-spoke distribution model simplifies supply chains by centralizing product packing and shipping at a hub, improving workforce productivity, optimizing route planning, and lowering logistical costs through fewer warehouses and transport means.

The Hub and Spoke Distribution Model for SMB's - Ware2Go - This model reduces transit times by strategically locating distribution centers near ports and fulfillment centers, improves service levels through inventory proximity, offsets freight costs by favoring full truckload shipments, lowers inventory carrying costs, and increases operational efficiency.

Spoke-hub distribution paradigm - Wikipedia - The hub-and-spoke system is a transport network topology where outlying points ("spokes") connect to a central hub, improving route efficiency over point-to-point systems; historically used by airlines like Delta since 1955 and later adopted in logistics and telecommunications.

dowidth.com

dowidth.com