Pick and pack logistics involves warehousing inventory, selecting individual items for orders, and packaging them for shipment, which enables greater control over stock and faster fulfillment. Drop shipping eliminates the need for inventory management by having suppliers ship products directly to customers, reducing overhead but potentially increasing delivery times. Explore the advantages and challenges of pick and pack versus drop shipping to optimize your supply chain strategy.

Why it is important

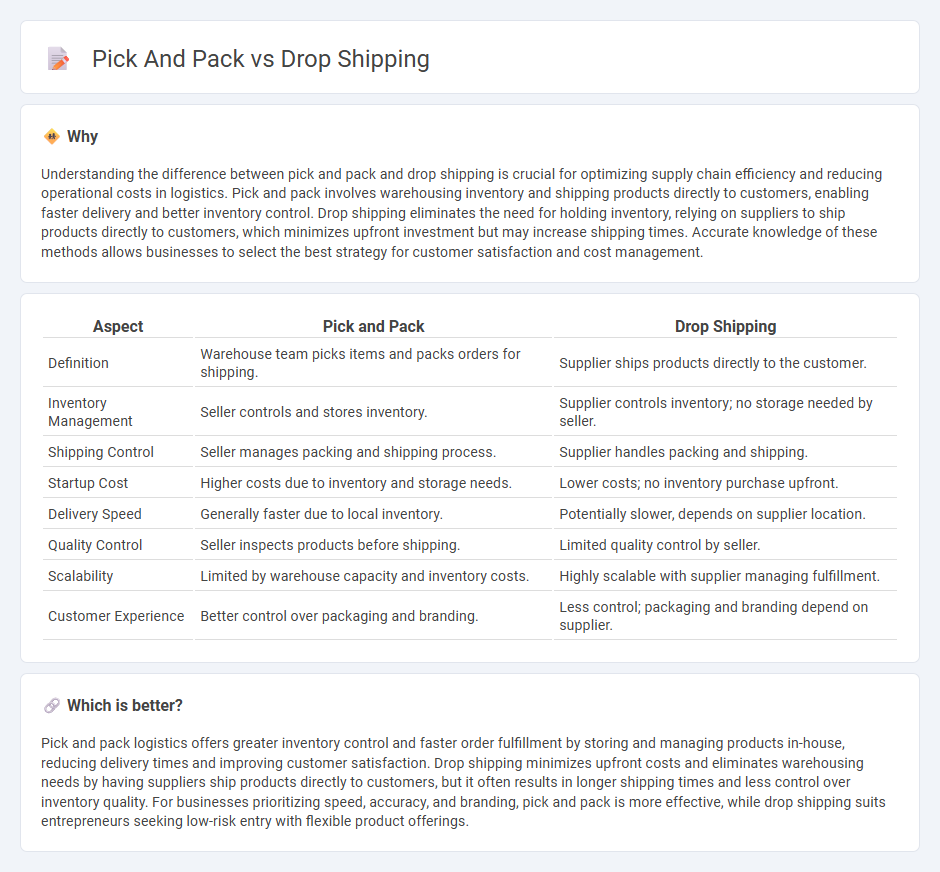

Understanding the difference between pick and pack and drop shipping is crucial for optimizing supply chain efficiency and reducing operational costs in logistics. Pick and pack involves warehousing inventory and shipping products directly to customers, enabling faster delivery and better inventory control. Drop shipping eliminates the need for holding inventory, relying on suppliers to ship products directly to customers, which minimizes upfront investment but may increase shipping times. Accurate knowledge of these methods allows businesses to select the best strategy for customer satisfaction and cost management.

Comparison Table

| Aspect | Pick and Pack | Drop Shipping |

|---|---|---|

| Definition | Warehouse team picks items and packs orders for shipping. | Supplier ships products directly to the customer. |

| Inventory Management | Seller controls and stores inventory. | Supplier controls inventory; no storage needed by seller. |

| Shipping Control | Seller manages packing and shipping process. | Supplier handles packing and shipping. |

| Startup Cost | Higher costs due to inventory and storage needs. | Lower costs; no inventory purchase upfront. |

| Delivery Speed | Generally faster due to local inventory. | Potentially slower, depends on supplier location. |

| Quality Control | Seller inspects products before shipping. | Limited quality control by seller. |

| Scalability | Limited by warehouse capacity and inventory costs. | Highly scalable with supplier managing fulfillment. |

| Customer Experience | Better control over packaging and branding. | Less control; packaging and branding depend on supplier. |

Which is better?

Pick and pack logistics offers greater inventory control and faster order fulfillment by storing and managing products in-house, reducing delivery times and improving customer satisfaction. Drop shipping minimizes upfront costs and eliminates warehousing needs by having suppliers ship products directly to customers, but it often results in longer shipping times and less control over inventory quality. For businesses prioritizing speed, accuracy, and branding, pick and pack is more effective, while drop shipping suits entrepreneurs seeking low-risk entry with flexible product offerings.

Connection

Pick and pack and drop shipping are connected through the streamlined order fulfillment process in logistics, where pick and pack involves selecting and packaging products from a warehouse, and drop shipping bypasses the seller's inventory by shipping directly from suppliers to customers. Efficient coordination between pick and pack operations and drop shipping ensures timely delivery, reduces inventory costs, and enhances supply chain agility. Integrating these methods optimizes order accuracy and customer satisfaction while minimizing handling and storage expenses.

Key Terms

Inventory Management

Drop shipping eliminates the need for inventory management by relying on suppliers to store and ship products directly to customers, reducing overhead costs and minimizing stock risks. Pick and pack requires businesses to maintain inventory in warehouses, where products are carefully stored, picked per order, and packed for shipment, providing greater control over stock and fulfillment quality. Explore the advantages and challenges of both models to optimize your inventory management strategy effectively.

Order Fulfillment

Drop shipping eliminates the need for inventory management by directly shipping products from suppliers to customers, while pick and pack involves storing, picking, and packaging items in a warehouse before shipment. Order fulfillment in drop shipping relies heavily on supplier reliability and real-time inventory updates, whereas pick and pack allows greater control over packaging quality and shipping speed. Explore the key differences and benefits of each method to optimize your order fulfillment strategy.

Shipping Model

Drop shipping involves shipping products directly from the supplier to the customer, eliminating the need for inventory storage and reducing fulfillment time. Pick and pack requires storing inventory in a warehouse where items are picked, packed, and shipped by the retailer, offering greater control over stock and packaging. Explore our in-depth guide to understand which shipping model best suits your business needs.

Source and External Links

Drop shipping - Wikipedia - Drop shipping is a retail business model where the seller accepts orders without holding stock, forwarding order details to a supplier who ships directly to customers; it minimizes initial investment and overhead but limits control over product quality and shipping logistics.

What Is Dropshipping and How Does It Work? (2025) - Shopify - Dropshipping involves partnering with a supplier who handles inventory, packaging, and shipping, while the retailer manages marketing and sales through an online store, forwarding customer orders to the supplier who ships directly to customers.

What Is Dropshipping and How Does It Work? - Wix.com - Dropshipping is a fulfillment method where the retailer does not stock inventory but sells products online and forwards orders to a third-party supplier who fulfills and ships the products directly to customers, focusing the retailer's role primarily on marketing and customer experience.

dowidth.com

dowidth.com