Pick and pack and cross docking are two critical logistics strategies that optimize warehouse efficiency and order fulfillment. Pick and pack involves selecting individual items from inventory to assemble customer orders, enhancing customization and accuracy in shipments. Explore the differences and applications of these methods to improve your supply chain management.

Why it is important

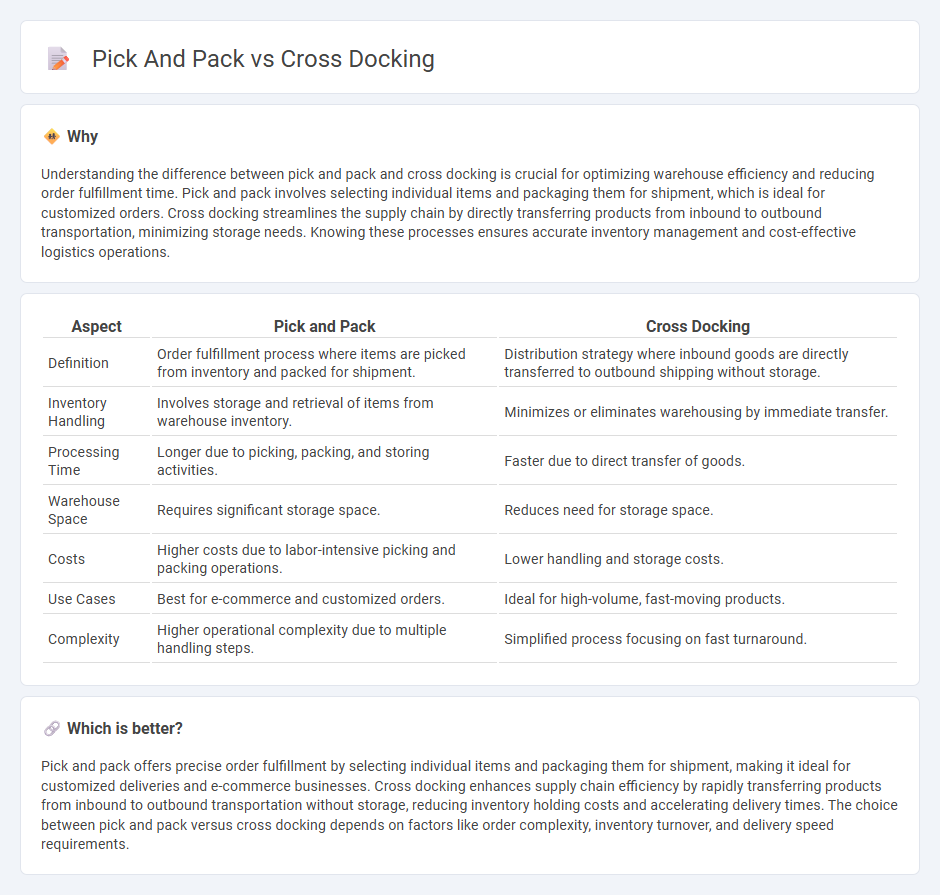

Understanding the difference between pick and pack and cross docking is crucial for optimizing warehouse efficiency and reducing order fulfillment time. Pick and pack involves selecting individual items and packaging them for shipment, which is ideal for customized orders. Cross docking streamlines the supply chain by directly transferring products from inbound to outbound transportation, minimizing storage needs. Knowing these processes ensures accurate inventory management and cost-effective logistics operations.

Comparison Table

| Aspect | Pick and Pack | Cross Docking |

|---|---|---|

| Definition | Order fulfillment process where items are picked from inventory and packed for shipment. | Distribution strategy where inbound goods are directly transferred to outbound shipping without storage. |

| Inventory Handling | Involves storage and retrieval of items from warehouse inventory. | Minimizes or eliminates warehousing by immediate transfer. |

| Processing Time | Longer due to picking, packing, and storing activities. | Faster due to direct transfer of goods. |

| Warehouse Space | Requires significant storage space. | Reduces need for storage space. |

| Costs | Higher costs due to labor-intensive picking and packing operations. | Lower handling and storage costs. |

| Use Cases | Best for e-commerce and customized orders. | Ideal for high-volume, fast-moving products. |

| Complexity | Higher operational complexity due to multiple handling steps. | Simplified process focusing on fast turnaround. |

Which is better?

Pick and pack offers precise order fulfillment by selecting individual items and packaging them for shipment, making it ideal for customized deliveries and e-commerce businesses. Cross docking enhances supply chain efficiency by rapidly transferring products from inbound to outbound transportation without storage, reducing inventory holding costs and accelerating delivery times. The choice between pick and pack versus cross docking depends on factors like order complexity, inventory turnover, and delivery speed requirements.

Connection

Pick and pack and cross docking are integral components of efficient logistics operations focused on reducing handling time and improving order fulfillment accuracy. Pick and pack involves selecting items from inventory and packaging them for shipment, while cross docking streamlines distribution by directly transferring goods from inbound to outbound transportation without long-term storage. Combining pick and pack with cross docking enhances supply chain speed, minimizes inventory holding costs, and optimizes warehouse throughput.

Key Terms

Inventory Flow

Cross docking accelerates inventory flow by transferring products directly from receiving to shipping with minimal storage, reducing handling time and storage costs. Pick and pack involves storing inventory until orders are received, then picking items from shelves and packing them for shipment, which increases storage requirements and processing time. Explore detailed strategies to optimize inventory flow and choose the best method for your supply chain needs.

Order Fulfillment

Cross docking minimizes storage time by directly transferring incoming goods to outbound shipments, streamlining order fulfillment and reducing lead times. Pick and pack involves selecting items from inventory and packaging them for shipment, offering more customization for complex orders. Discover how these strategies impact efficiency and customer satisfaction in order fulfillment.

Handling Time

Cross docking minimizes handling time by transferring products directly from inbound to outbound transportation, reducing storage delays and labor-intensive processes. Pick and pack involves handling individual items for order fulfillment, increasing handling time due to sorting, packing, and inventory movement. Explore deeper differences in efficiency and operational impacts between cross docking and pick and pack.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method that transfers goods directly from one transportation mode to another, minimizing storage by using methods such as continuous cross docking, consolidation arrangements, and de-consolidation to speed up handling and reduce costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy transferring goods from inbound to outbound vehicles with minimal or no storage, used to accelerate delivery, optimize inventory, reduce warehouse space, and cut transportation and labor costs.

Cross-docking: meaning, benefits, types, uses | Red Stag Fulfillment - Cross-docking moves inbound inventory directly to outbound trucks bypassing storage and picking, which is especially useful for eCommerce and retail distribution centers to speed fulfillment and support just-in-time inventory management.

dowidth.com

dowidth.com