Milk run logistics involves a scheduled, circular route to collect goods from multiple suppliers, optimizing load efficiency and reducing transportation costs. Cross docking streamlines distribution by transferring products directly from inbound to outbound transportation with minimal storage, accelerating delivery times and lowering inventory holding costs. Explore the benefits and applications of milk run logistics versus cross docking to enhance your supply chain management.

Why it is important

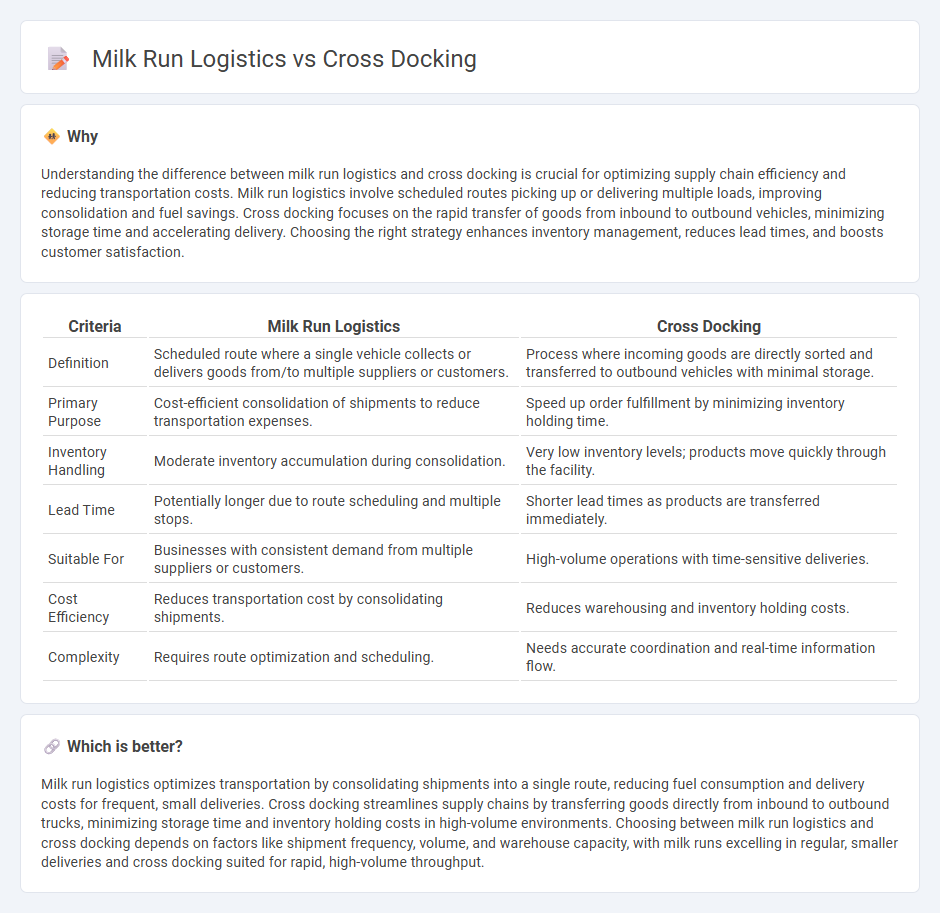

Understanding the difference between milk run logistics and cross docking is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run logistics involve scheduled routes picking up or delivering multiple loads, improving consolidation and fuel savings. Cross docking focuses on the rapid transfer of goods from inbound to outbound vehicles, minimizing storage time and accelerating delivery. Choosing the right strategy enhances inventory management, reduces lead times, and boosts customer satisfaction.

Comparison Table

| Criteria | Milk Run Logistics | Cross Docking |

|---|---|---|

| Definition | Scheduled route where a single vehicle collects or delivers goods from/to multiple suppliers or customers. | Process where incoming goods are directly sorted and transferred to outbound vehicles with minimal storage. |

| Primary Purpose | Cost-efficient consolidation of shipments to reduce transportation expenses. | Speed up order fulfillment by minimizing inventory holding time. |

| Inventory Handling | Moderate inventory accumulation during consolidation. | Very low inventory levels; products move quickly through the facility. |

| Lead Time | Potentially longer due to route scheduling and multiple stops. | Shorter lead times as products are transferred immediately. |

| Suitable For | Businesses with consistent demand from multiple suppliers or customers. | High-volume operations with time-sensitive deliveries. |

| Cost Efficiency | Reduces transportation cost by consolidating shipments. | Reduces warehousing and inventory holding costs. |

| Complexity | Requires route optimization and scheduling. | Needs accurate coordination and real-time information flow. |

Which is better?

Milk run logistics optimizes transportation by consolidating shipments into a single route, reducing fuel consumption and delivery costs for frequent, small deliveries. Cross docking streamlines supply chains by transferring goods directly from inbound to outbound trucks, minimizing storage time and inventory holding costs in high-volume environments. Choosing between milk run logistics and cross docking depends on factors like shipment frequency, volume, and warehouse capacity, with milk runs excelling in regular, smaller deliveries and cross docking suited for rapid, high-volume throughput.

Connection

Milk run logistics and cross docking are connected by their focus on optimizing supply chain efficiency through streamlined transportation and handling processes. Milk run logistics involves scheduled, multi-stop routes to collect or deliver goods, reducing transportation costs and inventory levels, while cross docking facilitates rapid transfer of products from inbound to outbound shipments without storage, minimizing warehouse time. Integrating milk run logistics with cross docking enhances synchronization of deliveries and shipments, leading to faster turnaround times and reduced operational expenses.

Key Terms

Transshipment Point

Cross docking streamlines distribution by unloading inbound goods directly onto outbound transport at a transshipment point, minimizing storage time and handling costs. Milk run logistics involves scheduled, consolidated pick-ups and deliveries to optimize routing and reduce transportation expenses through a central transshipment hub. Explore how selecting the ideal transshipment point enhances efficiency in both cross docking and milk run operations.

Route Optimization

Cross docking minimizes warehouse storage time by directly transferring goods from inbound to outbound transportation, enhancing route efficiency and reducing delivery times. Milk run logistics consolidates multiple deliveries into a single route, optimizing vehicle capacity and reducing transportation costs through systematic route planning. Explore detailed comparisons and strategies to optimize your supply chain routes effectively.

Inventory Turnover

Cross docking significantly increases inventory turnover by minimizing storage time and moving goods directly from receiving to shipping, reducing holding costs and accelerating cash flow. Milk run logistics optimizes inventory turnover through scheduled, consolidated deliveries that reduce stock variability and improve supply chain synchronization. Explore how these strategies can enhance your inventory management and operational efficiency.

Source and External Links

Cross Docking: Definition, History, and Process - Cross docking is a shipping method that transfers goods directly from inbound to outbound transportation to minimize storage and speed delivery; it includes methods like continuous cross docking, consolidation, and de-consolidation.

What Is Cross-Docking? Definition, Types & Advantages - Cross-docking is a supply chain technique where goods move from receiving docks directly to shipping docks with little or no storage time, improving efficiency and speed especially for high-volume or perishable goods.

Cross-docking: meaning, benefits, types, uses - Cross-docking accelerates order fulfillment by moving products straight from receiving to outbound trucks without inventory storage, commonly used in retail and eCommerce distribution to reduce handling time and costs.

dowidth.com

dowidth.com