Print on demand offers entrepreneurs a low-risk, scalable solution by producing products only after customer orders, minimizing upfront investment and inventory costs. Manufacturing involves larger initial capital expenditure with bulk production, enabling lower per-unit costs and greater control over product quality and customization. Explore the advantages and challenges of print on demand versus manufacturing to determine the best strategy for your business growth.

Why it is important

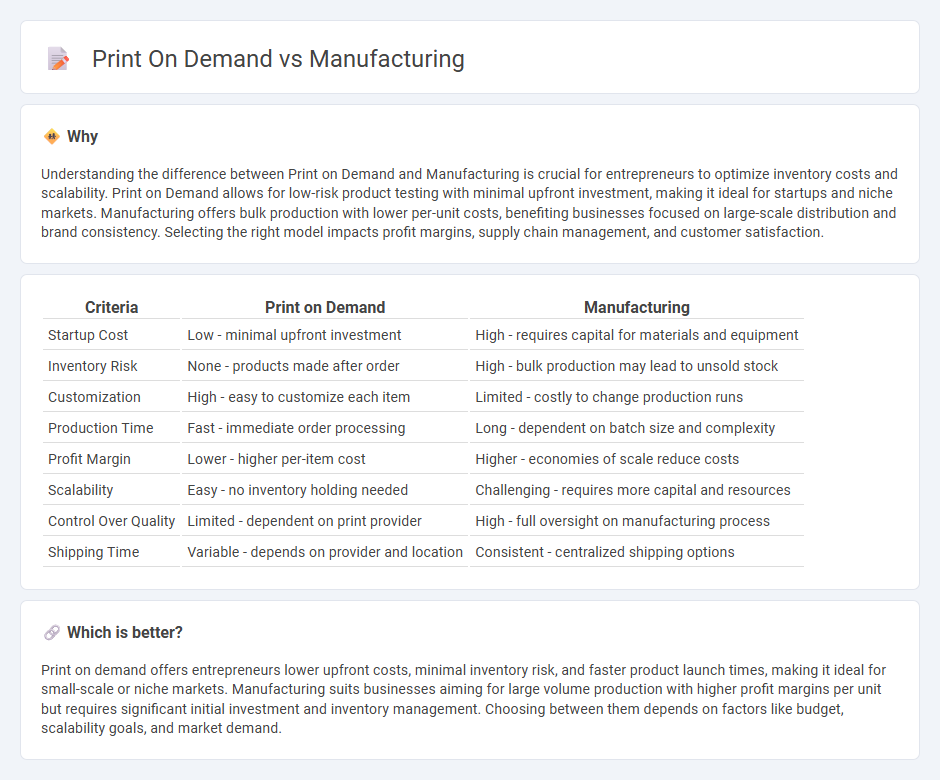

Understanding the difference between Print on Demand and Manufacturing is crucial for entrepreneurs to optimize inventory costs and scalability. Print on Demand allows for low-risk product testing with minimal upfront investment, making it ideal for startups and niche markets. Manufacturing offers bulk production with lower per-unit costs, benefiting businesses focused on large-scale distribution and brand consistency. Selecting the right model impacts profit margins, supply chain management, and customer satisfaction.

Comparison Table

| Criteria | Print on Demand | Manufacturing |

|---|---|---|

| Startup Cost | Low - minimal upfront investment | High - requires capital for materials and equipment |

| Inventory Risk | None - products made after order | High - bulk production may lead to unsold stock |

| Customization | High - easy to customize each item | Limited - costly to change production runs |

| Production Time | Fast - immediate order processing | Long - dependent on batch size and complexity |

| Profit Margin | Lower - higher per-item cost | Higher - economies of scale reduce costs |

| Scalability | Easy - no inventory holding needed | Challenging - requires more capital and resources |

| Control Over Quality | Limited - dependent on print provider | High - full oversight on manufacturing process |

| Shipping Time | Variable - depends on provider and location | Consistent - centralized shipping options |

Which is better?

Print on demand offers entrepreneurs lower upfront costs, minimal inventory risk, and faster product launch times, making it ideal for small-scale or niche markets. Manufacturing suits businesses aiming for large volume production with higher profit margins per unit but requires significant initial investment and inventory management. Choosing between them depends on factors like budget, scalability goals, and market demand.

Connection

Print on demand and manufacturing are interconnected through their shared reliance on production processes tailored to specific customer demands, enabling entrepreneurs to minimize inventory risks and reduce upfront costs. Using digital printing technologies and streamlined manufacturing workflows, entrepreneurs can quickly produce customized products such as apparel, accessories, and home decor, aligning supply closely with market trends and consumer preferences. This synergy empowers small businesses to scale efficiently, leverage rapid prototyping, and respond agilely to changing market conditions.

Key Terms

Inventory Management

Manufacturing requires extensive inventory management to handle raw materials, work-in-progress, and finished goods, creating challenges in storage and capital tied up in stock. Print on demand eliminates the need for large inventory by producing items only after an order is placed, significantly reducing overhead and minimizing risks of unsold products. Explore deeper insights to optimize your supply chain strategies effectively.

Supply Chain

Manufacturing relies on bulk production and extensive inventory management, leading to complex supply chains involving raw materials sourcing, warehousing, and distribution networks. Print on demand streamlines the supply chain by producing items only after order placement, minimizing inventory costs and reducing lead times. Explore the advantages and challenges of each model to optimize your supply chain strategy effectively.

Customization

Manufacturing offers extensive customization through tailored production runs, allowing for unique materials, designs, and intricate details suited to specific client needs. Print on demand provides rapid customization options with lower upfront costs, ideal for personalized products and small batches without inventory risk. Explore how these customization methods impact product quality and market agility to determine the best fit for your business.

Source and External Links

Manufacturing - Manufacturing is the creation of goods using labor, machines, tools, and chemical or biological processes, spanning from handicraft to large-scale industrial production that transforms raw materials into finished products for consumers or other manufacturers.

What is Manufacturing: The Ultimate Guide (2024) -- Katana - Manufacturing involves converting raw materials, parts, and components into finished products via labor, tools, and machinery, and can include continuous or batch production processes tailored to consumer demand.

Manufacturing in the United States - The manufacturing sector contributes about 10% of U.S. GDP, employs 13 million people, and is a key driver of innovation, exports, and economic strength, with ongoing investment in workforce and technology.

dowidth.com

dowidth.com