Resilient supply chains prioritize adaptability and risk management by incorporating redundancy, real-time data analytics, and diversified sourcing to withstand disruptions. In contrast, linear supply chains focus on efficiency and cost reduction through streamlined, sequential processes with minimal inventory buffers. Explore how these differing approaches impact economic stability and business continuity.

Why it is important

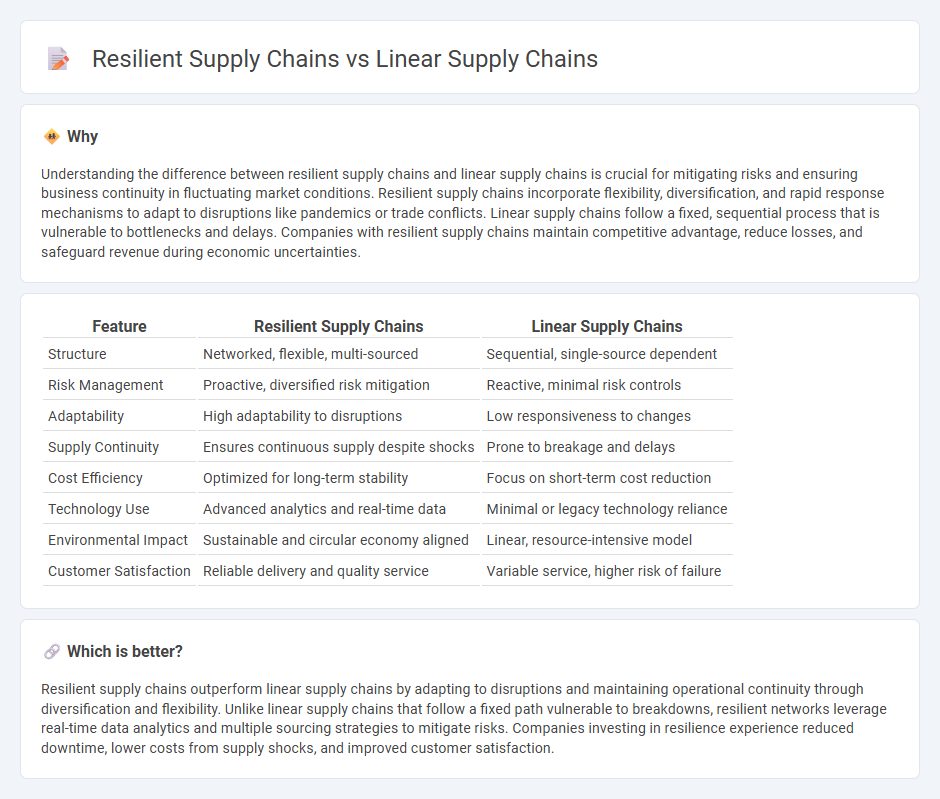

Understanding the difference between resilient supply chains and linear supply chains is crucial for mitigating risks and ensuring business continuity in fluctuating market conditions. Resilient supply chains incorporate flexibility, diversification, and rapid response mechanisms to adapt to disruptions like pandemics or trade conflicts. Linear supply chains follow a fixed, sequential process that is vulnerable to bottlenecks and delays. Companies with resilient supply chains maintain competitive advantage, reduce losses, and safeguard revenue during economic uncertainties.

Comparison Table

| Feature | Resilient Supply Chains | Linear Supply Chains |

|---|---|---|

| Structure | Networked, flexible, multi-sourced | Sequential, single-source dependent |

| Risk Management | Proactive, diversified risk mitigation | Reactive, minimal risk controls |

| Adaptability | High adaptability to disruptions | Low responsiveness to changes |

| Supply Continuity | Ensures continuous supply despite shocks | Prone to breakage and delays |

| Cost Efficiency | Optimized for long-term stability | Focus on short-term cost reduction |

| Technology Use | Advanced analytics and real-time data | Minimal or legacy technology reliance |

| Environmental Impact | Sustainable and circular economy aligned | Linear, resource-intensive model |

| Customer Satisfaction | Reliable delivery and quality service | Variable service, higher risk of failure |

Which is better?

Resilient supply chains outperform linear supply chains by adapting to disruptions and maintaining operational continuity through diversification and flexibility. Unlike linear supply chains that follow a fixed path vulnerable to breakdowns, resilient networks leverage real-time data analytics and multiple sourcing strategies to mitigate risks. Companies investing in resilience experience reduced downtime, lower costs from supply shocks, and improved customer satisfaction.

Connection

Resilient supply chains incorporate flexibility and adaptability to withstand disruptions, unlike traditional linear supply chains that follow a rigid, sequential flow of goods and information. The integration of real-time data analytics and diversified sourcing strategies enhances supply chain resilience by enabling proactive responses to demand fluctuations and supply shocks. Companies shifting from linear to resilient models benefit from increased operational continuity, reduced risk exposure, and improved customer satisfaction in volatile economic environments.

Key Terms

Just-in-Time (JIT)

Linear supply chains rely heavily on Just-in-Time (JIT) inventory systems to minimize costs by reducing stock levels and streamlining production schedules, but they often lack flexibility during disruptions. Resilient supply chains integrate JIT with buffer stocks and diversified suppliers to maintain agility and continuity in the face of unexpected shocks. Explore strategies to balance efficiency and resilience in modern supply chain management.

Redundancy

Linear supply chains operate with minimal redundancy, emphasizing efficiency and cost reduction by maintaining a single sourcing or production path. Resilient supply chains incorporate strategic redundancy, such as multiple suppliers and diversified logistics routes, to mitigate risks and enhance recovery from disruptions. Explore how redundancy transforms supply chain robustness and ensures business continuity in uncertain environments.

Flexibility

Linear supply chains prioritize a straightforward, sequential flow of materials and information, optimizing efficiency but often lacking flexibility to adapt to disruptions. Resilient supply chains incorporate flexibility by enabling alternative sourcing, dynamic inventory management, and rapid response mechanisms to maintain operations amid uncertainties. Explore more about how flexible supply chains enhance robustness and business continuity in volatile markets.

Source and External Links

Linear vs. Circular Supply Chains - This article discusses the traditional linear supply chain model and its limitations, highlighting the shift towards circular supply chains for sustainability and efficiency.

The Anatomy of a Circular Supply Chain - This resource compares linear supply chains with circular ones, focusing on how circular models use reverse logistics and recycling to reduce waste and increase sustainability.

Supply chains and the circular economy - This overview explains how traditional linear supply chains are being reconfigured to align with circular economy principles, emphasizing resilience, cost reduction, and environmental benefits.

dowidth.com

dowidth.com