Fragmented supply chains involve multiple independent entities operating with limited coordination, leading to inefficiencies and higher risks of disruption, especially in global trade environments. Integrated supply chains utilize seamless collaboration and data sharing across suppliers, manufacturers, and distributors to enhance efficiency, reduce costs, and improve responsiveness to market demands. Discover how choosing the right supply chain model can impact business resilience and competitive advantage.

Why it is important

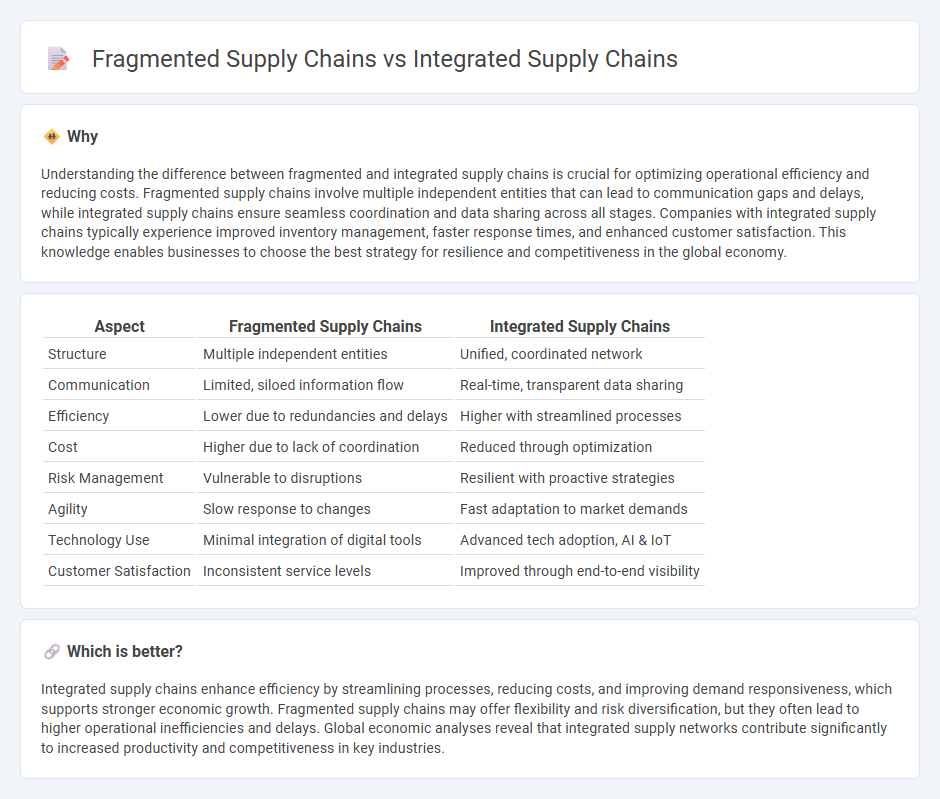

Understanding the difference between fragmented and integrated supply chains is crucial for optimizing operational efficiency and reducing costs. Fragmented supply chains involve multiple independent entities that can lead to communication gaps and delays, while integrated supply chains ensure seamless coordination and data sharing across all stages. Companies with integrated supply chains typically experience improved inventory management, faster response times, and enhanced customer satisfaction. This knowledge enables businesses to choose the best strategy for resilience and competitiveness in the global economy.

Comparison Table

| Aspect | Fragmented Supply Chains | Integrated Supply Chains |

|---|---|---|

| Structure | Multiple independent entities | Unified, coordinated network |

| Communication | Limited, siloed information flow | Real-time, transparent data sharing |

| Efficiency | Lower due to redundancies and delays | Higher with streamlined processes |

| Cost | Higher due to lack of coordination | Reduced through optimization |

| Risk Management | Vulnerable to disruptions | Resilient with proactive strategies |

| Agility | Slow response to changes | Fast adaptation to market demands |

| Technology Use | Minimal integration of digital tools | Advanced tech adoption, AI & IoT |

| Customer Satisfaction | Inconsistent service levels | Improved through end-to-end visibility |

Which is better?

Integrated supply chains enhance efficiency by streamlining processes, reducing costs, and improving demand responsiveness, which supports stronger economic growth. Fragmented supply chains may offer flexibility and risk diversification, but they often lead to higher operational inefficiencies and delays. Global economic analyses reveal that integrated supply networks contribute significantly to increased productivity and competitiveness in key industries.

Connection

Fragmented supply chains rely on multiple independent suppliers, causing delays and inefficiencies, while integrated supply chains unify processes through centralized coordination and real-time data sharing, improving responsiveness and reducing costs. The transition from fragmentation to integration leverages technological advancements like IoT and AI to streamline operations and enhance supply chain visibility. This connection drives economic resilience by optimizing resource allocation, minimizing disruptions, and boosting overall productivity.

Key Terms

Coordination

Integrated supply chains enhance coordination through centralized information systems and collaborative planning, leading to improved efficiency and reduced lead times. Fragmented supply chains suffer from communication gaps and misaligned objectives, causing delays and increased costs. Explore how optimizing coordination can transform supply chain performance.

Efficiency

Integrated supply chains enhance efficiency by enabling seamless communication, real-time data sharing, and coordinated logistics across all partners, reducing delays and costs. Fragmented supply chains often suffer from information silos and misaligned processes, leading to increased lead times and higher operational inefficiencies. Discover how optimizing your supply chain integration can significantly boost your business performance and competitiveness.

Resilience

Integrated supply chains enhance resilience by enabling seamless information flow, real-time data sharing, and coordinated risk management across suppliers and distributors, reducing downtime during disruptions. Fragmented supply chains often suffer from communication gaps and inefficient resource allocation, making them more vulnerable to delays and increased recovery costs. Explore strategies to strengthen supply chain resilience through integration and collaboration for a competitive edge.

Source and External Links

What Is Integrated Supply Chain Management? - Integrated supply chain management involves coordinated planning, execution, and visibility across all segments of the supply chain, leveraging shared software, real-time data, and advanced technologies like AI and automation to streamline operations and respond quickly to disruptions.

An integrated supply chain works like this - An integrated supply chain is a network of suppliers, manufacturers, and distributors that share information and coordinate processes to eliminate cost overruns, improve efficiency, enhance product traceability, and adopt a customer-centric vision by enabling holistic decision-making based on accurate, shared data.

Key Types of Supply Chain Collaboration Explained - Integrated supply chains employ strategies such as collaborative planning, vendor-managed inventory, coordinated production and distribution, and joint ventures to reduce costs, improve inventory management, increase visibility, and enhance customer service through closer coordination between all supply chain partners.

dowidth.com

dowidth.com