Operational excellence mapping focuses on aligning business processes with strategic goals to enhance efficiency and reduce waste, ensuring continuous improvement across all organizational levels. Value Stream Mapping specifically targets identifying and eliminating non-value-added activities within a production or service workflow, highlighting opportunities for streamlined operations and cost savings. Discover how these methodologies can transform your business processes by exploring their unique benefits and applications.

Why it is important

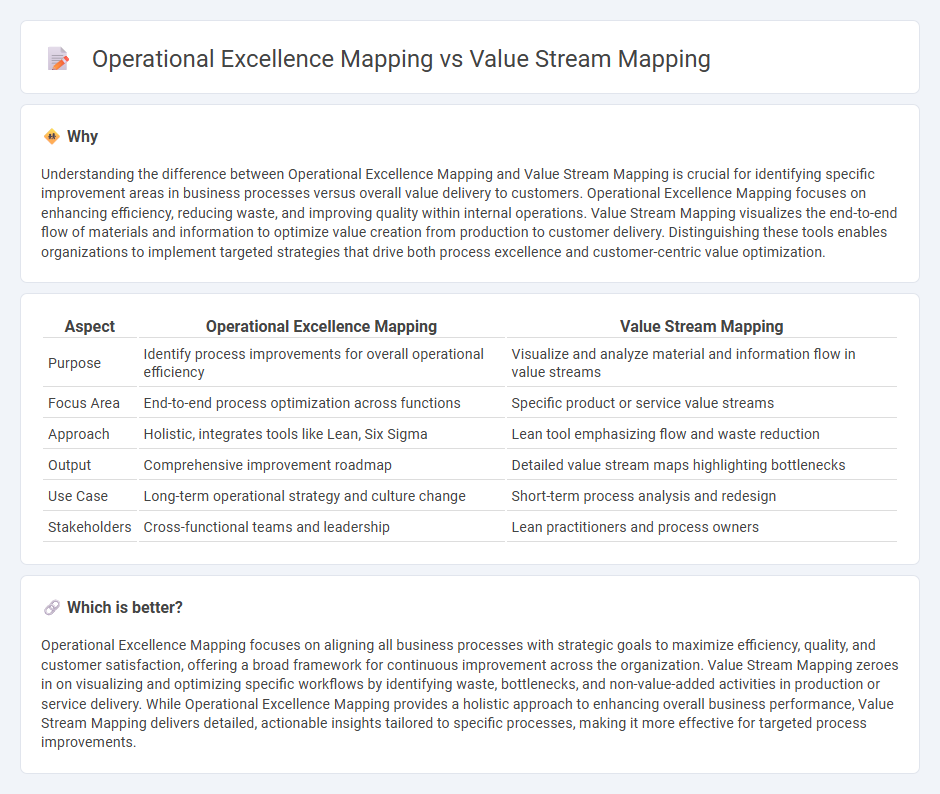

Understanding the difference between Operational Excellence Mapping and Value Stream Mapping is crucial for identifying specific improvement areas in business processes versus overall value delivery to customers. Operational Excellence Mapping focuses on enhancing efficiency, reducing waste, and improving quality within internal operations. Value Stream Mapping visualizes the end-to-end flow of materials and information to optimize value creation from production to customer delivery. Distinguishing these tools enables organizations to implement targeted strategies that drive both process excellence and customer-centric value optimization.

Comparison Table

| Aspect | Operational Excellence Mapping | Value Stream Mapping |

|---|---|---|

| Purpose | Identify process improvements for overall operational efficiency | Visualize and analyze material and information flow in value streams |

| Focus Area | End-to-end process optimization across functions | Specific product or service value streams |

| Approach | Holistic, integrates tools like Lean, Six Sigma | Lean tool emphasizing flow and waste reduction |

| Output | Comprehensive improvement roadmap | Detailed value stream maps highlighting bottlenecks |

| Use Case | Long-term operational strategy and culture change | Short-term process analysis and redesign |

| Stakeholders | Cross-functional teams and leadership | Lean practitioners and process owners |

Which is better?

Operational Excellence Mapping focuses on aligning all business processes with strategic goals to maximize efficiency, quality, and customer satisfaction, offering a broad framework for continuous improvement across the organization. Value Stream Mapping zeroes in on visualizing and optimizing specific workflows by identifying waste, bottlenecks, and non-value-added activities in production or service delivery. While Operational Excellence Mapping provides a holistic approach to enhancing overall business performance, Value Stream Mapping delivers detailed, actionable insights tailored to specific processes, making it more effective for targeted process improvements.

Connection

Operational excellence mapping and Value Stream Mapping (VSM) are interconnected tools used to identify inefficiencies and streamline processes in consulting engagements. Operational excellence mapping provides a strategic framework for continuous improvement, while VSM offers a detailed visual representation of workflows to pinpoint value-adding and non-value-adding activities. Together, they enable consultants to optimize process performance by aligning operational goals with value creation throughout the organization.

Key Terms

Process Flow

Value Stream Mapping (VSM) focuses on visualizing the flow of materials and information through the entire production process to identify waste and improve efficiency, while Operational Excellence mapping emphasizes aligning processes with strategic goals to enhance overall organizational performance. Both techniques analyze process flow but differ in scope and objectives; VSM targets specific value-added activities, whereas Operational Excellence mapping incorporates broader performance metrics and continuous improvement frameworks. Explore detailed methodologies and practical applications to maximize process optimization.

Waste Identification

Value Stream Mapping (VSM) targets the entire production process to identify bottlenecks and non-value-added activities, emphasizing waste elimination in manufacturing and service operations. Operational Excellence Mapping expands beyond waste by integrating lean principles and continuous improvement strategies across organizational functions for sustainable performance. Explore the nuances between these methodologies to enhance your waste identification and operational efficiency.

Continuous Improvement

Value Stream Mapping (VSM) targets identifying waste and optimizing processes within production or service delivery to enhance flow and reduce lead times. Operational Excellence Mapping extends beyond VSM by integrating strategic goals, performance metrics, and cultural change initiatives to embed continuous improvement organization-wide. Explore how each methodology drives sustainable improvement and aligns with your business objectives in greater detail.

Source and External Links

Value Stream Mapping [Definition, Process & Examples] - Value Stream Mapping (VSM) is a method where a team maps all steps of a recurring process to analyze and identify which steps add value and which are wasteful, aiming to improve efficiency and reduce waste by visualizing the entire process flow, including materials and information.

Value-stream mapping - VSM is a lean-management tool that visually represents all critical steps of a process from start to delivery, quantifying time and volume, to identify and remove waste, thereby increasing efficiency and productivity across industries such as manufacturing, logistics, healthcare, and software development.

Value Stream Mapping Overview - VSM diagrams every step involved in the material and information flows required to bring a product from order to delivery, starting with a current state map followed by a future state map to guide continuous improvement and waste elimination, rooted in Toyota Production System practices.

dowidth.com

dowidth.com