Digital lean transformation focuses on integrating advanced technologies like AI and IoT to streamline processes, reduce waste, and enhance efficiency across organizations. Supply chain optimization emphasizes improving logistics, inventory management, and supplier collaboration to minimize costs and maximize delivery speed. Explore how tailored consulting solutions can drive innovation and performance in both domains.

Why it is important

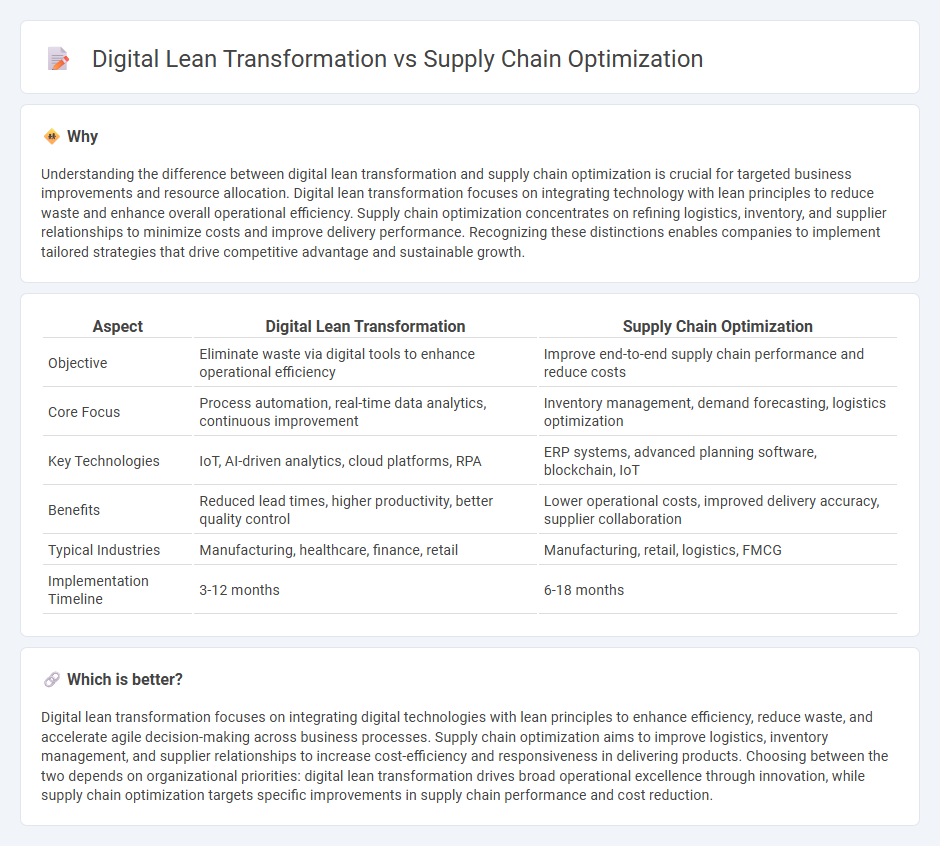

Understanding the difference between digital lean transformation and supply chain optimization is crucial for targeted business improvements and resource allocation. Digital lean transformation focuses on integrating technology with lean principles to reduce waste and enhance overall operational efficiency. Supply chain optimization concentrates on refining logistics, inventory, and supplier relationships to minimize costs and improve delivery performance. Recognizing these distinctions enables companies to implement tailored strategies that drive competitive advantage and sustainable growth.

Comparison Table

| Aspect | Digital Lean Transformation | Supply Chain Optimization |

|---|---|---|

| Objective | Eliminate waste via digital tools to enhance operational efficiency | Improve end-to-end supply chain performance and reduce costs |

| Core Focus | Process automation, real-time data analytics, continuous improvement | Inventory management, demand forecasting, logistics optimization |

| Key Technologies | IoT, AI-driven analytics, cloud platforms, RPA | ERP systems, advanced planning software, blockchain, IoT |

| Benefits | Reduced lead times, higher productivity, better quality control | Lower operational costs, improved delivery accuracy, supplier collaboration |

| Typical Industries | Manufacturing, healthcare, finance, retail | Manufacturing, retail, logistics, FMCG |

| Implementation Timeline | 3-12 months | 6-18 months |

Which is better?

Digital lean transformation focuses on integrating digital technologies with lean principles to enhance efficiency, reduce waste, and accelerate agile decision-making across business processes. Supply chain optimization aims to improve logistics, inventory management, and supplier relationships to increase cost-efficiency and responsiveness in delivering products. Choosing between the two depends on organizational priorities: digital lean transformation drives broad operational excellence through innovation, while supply chain optimization targets specific improvements in supply chain performance and cost reduction.

Connection

Digital lean transformation enhances supply chain optimization by integrating real-time data analytics and automation to eliminate inefficiencies and reduce waste. This alignment enables agile decision-making and improves resource allocation, driving cost savings and faster delivery times. Optimized supply chains leverage digital lean principles to foster continuous improvement and resilience in dynamic market environments.

Key Terms

Process Efficiency

Supply chain optimization enhances process efficiency by integrating advanced analytics and real-time data to minimize waste, reduce lead times, and improve inventory management. Digital lean transformation leverages IoT, AI, and automation to create a seamless workflow that eliminates non-value-added activities while promoting continuous improvement. Explore in-depth strategies and technology impacts on process efficiency in both approaches to maximize operational excellence.

Data-Driven Decision Making

Supply chain optimization leverages advanced analytics to enhance inventory management, demand forecasting, and logistics efficiency, enabling data-driven decision making that reduces costs and improves service levels. Digital lean transformation integrates IoT, AI, and automation to streamline processes, eliminate waste, and foster continuous improvement through real-time data insights. Explore how businesses can harness these strategies to unlock superior operational performance and agility.

End-to-End Visibility

End-to-end visibility in supply chain optimization enhances real-time tracking, reduces bottlenecks, and improves demand forecasting accuracy by integrating IoT sensors, advanced analytics, and AI-driven platforms. Digital lean transformation streamlines processes by eliminating waste, automating workflows, and enhancing transparency across the entire value chain to boost efficiency and responsiveness. Discover how combining these strategies drives innovation and competitive advantage in modern supply networks.

Source and External Links

The Ultimate Guide to Supply Chain Optimization - Order.co - Supply chain optimization improves production and distribution to achieve higher cost efficiency and quality using tactics like assessing current practices, improving planning, continuous negotiation, expanding analytics, and automating processes.

What is Supply Chain Optimization? - Tibco - Supply chain optimization involves adjusting operations for peak efficiency by focusing on cost optimization, inventory optimization, and network optimization to enhance quality, reduce waste, and handle supply chain changes effectively.

What Is Supply Chain Optimization? - IBM - Supply chain optimization uses technologies like AI, blockchain, and IoT to improve efficiency from network design and inventory planning to execution applications, ensuring customer satisfaction while balancing profitability and sustainability.

dowidth.com

dowidth.com