Consulting in digital twin strategy focuses on creating virtual replicas of physical assets to optimize performance, reduce downtime, and predict maintenance needs. Supply chain digitization consulting emphasizes integrating IoT, AI, and blockchain technologies to enhance transparency, agility, and efficiency across the supply network. Explore how these approaches can transform your business operations by learning more about their distinct benefits and implementation methods.

Why it is important

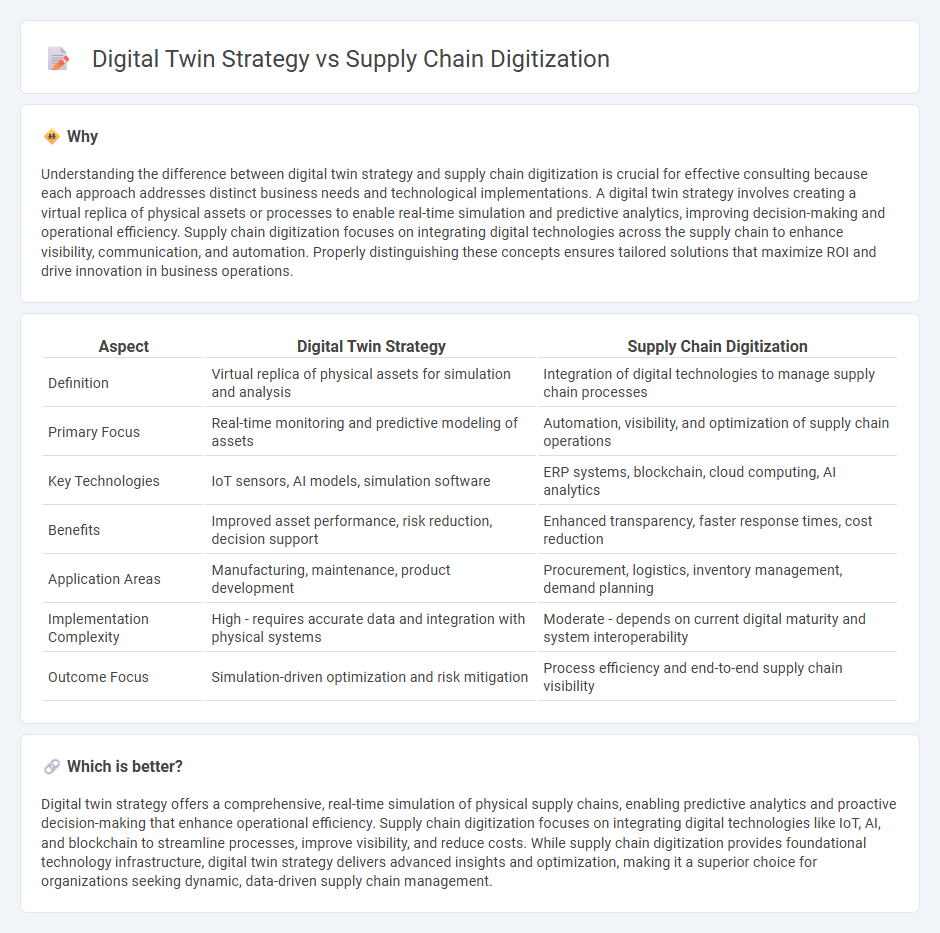

Understanding the difference between digital twin strategy and supply chain digitization is crucial for effective consulting because each approach addresses distinct business needs and technological implementations. A digital twin strategy involves creating a virtual replica of physical assets or processes to enable real-time simulation and predictive analytics, improving decision-making and operational efficiency. Supply chain digitization focuses on integrating digital technologies across the supply chain to enhance visibility, communication, and automation. Properly distinguishing these concepts ensures tailored solutions that maximize ROI and drive innovation in business operations.

Comparison Table

| Aspect | Digital Twin Strategy | Supply Chain Digitization |

|---|---|---|

| Definition | Virtual replica of physical assets for simulation and analysis | Integration of digital technologies to manage supply chain processes |

| Primary Focus | Real-time monitoring and predictive modeling of assets | Automation, visibility, and optimization of supply chain operations |

| Key Technologies | IoT sensors, AI models, simulation software | ERP systems, blockchain, cloud computing, AI analytics |

| Benefits | Improved asset performance, risk reduction, decision support | Enhanced transparency, faster response times, cost reduction |

| Application Areas | Manufacturing, maintenance, product development | Procurement, logistics, inventory management, demand planning |

| Implementation Complexity | High - requires accurate data and integration with physical systems | Moderate - depends on current digital maturity and system interoperability |

| Outcome Focus | Simulation-driven optimization and risk mitigation | Process efficiency and end-to-end supply chain visibility |

Which is better?

Digital twin strategy offers a comprehensive, real-time simulation of physical supply chains, enabling predictive analytics and proactive decision-making that enhance operational efficiency. Supply chain digitization focuses on integrating digital technologies like IoT, AI, and blockchain to streamline processes, improve visibility, and reduce costs. While supply chain digitization provides foundational technology infrastructure, digital twin strategy delivers advanced insights and optimization, making it a superior choice for organizations seeking dynamic, data-driven supply chain management.

Connection

Digital twin strategy enables real-time simulation and analysis of supply chain processes, enhancing visibility and decision-making accuracy. Supply chain digitization integrates IoT, AI, and data analytics, providing comprehensive data that powers the digital twin models for precise forecasting and risk management. Together, they drive operational efficiency, reduce downtime, and optimize inventory levels in complex supply networks.

Key Terms

Real-time Data Integration

Supply chain digitization involves converting traditional supply chain processes into digital formats to enhance visibility and efficiency through real-time data integration across suppliers, inventory, and transportation networks. Digital twin strategy creates a virtual replica of the entire supply chain, enabling simulation and proactive decision-making by analyzing real-time data streams for predictive insights and risk mitigation. Discover how leveraging real-time data integration in both approaches can revolutionize supply chain management.

Process Automation

Supply chain digitization enhances process automation by integrating IoT devices, AI analytics, and real-time data to streamline operations and reduce manual interventions. Digital twin strategies create virtual replicas of supply chain systems, enabling advanced simulation and predictive maintenance to optimize workflows and identify bottlenecks before they occur. Discover how combining these technologies can revolutionize your supply chain efficiency.

Simulation Modeling

Supply chain digitization enhances data integration and real-time visibility across logistics, inventory, and demand forecasting, streamlining operations for greater efficiency. Digital twin strategy leverages advanced simulation modeling to create virtual replicas of supply chain processes, allowing scenario testing and predictive analysis to optimize decision-making. Explore how combining these approaches transforms supply chain resilience and performance.

Source and External Links

What Is Supply Chain Digitization & Why Is It Important? - Supply chain digitization replaces manual or analog processes in ecommerce with digital solutions, optimizing data management, process integration, and the use of digital tools in physical execution for greater efficiency and flexibility.

What Is Supply Chain Digitization? Benefits, Challenges ... - It automates and optimizes supply chain operations by eliminating paper-based, siloed processes and implementing technology for interconnected, data-driven workflows, enabling real-time tracking, automation, and advanced analytics.

Navigating the Digital Supply Chain Revolution - Digital supply chains leverage automation, data analytics, and integrated software platforms, along with technologies like IoT, AI, ML, and blockchain, to enhance efficiency, visibility, and responsiveness across the supply network.

dowidth.com

dowidth.com