Digital twin consulting focuses on creating virtual replicas of physical assets to optimize performance and predict maintenance needs, enhancing operational efficiency. Smart manufacturing consulting integrates IoT, AI, and data analytics to streamline production processes and improve product quality through real-time decision-making. Explore our expert consulting services to discover how digital twin and smart manufacturing solutions can transform your business.

Why it is important

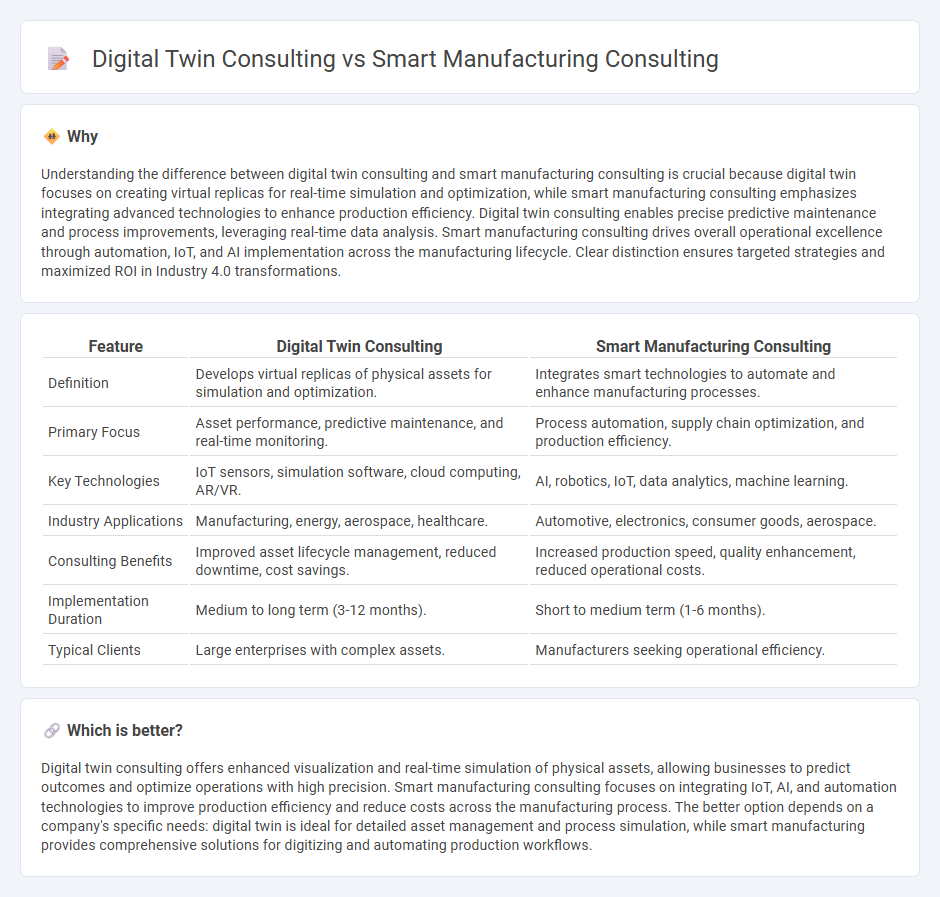

Understanding the difference between digital twin consulting and smart manufacturing consulting is crucial because digital twin focuses on creating virtual replicas for real-time simulation and optimization, while smart manufacturing consulting emphasizes integrating advanced technologies to enhance production efficiency. Digital twin consulting enables precise predictive maintenance and process improvements, leveraging real-time data analysis. Smart manufacturing consulting drives overall operational excellence through automation, IoT, and AI implementation across the manufacturing lifecycle. Clear distinction ensures targeted strategies and maximized ROI in Industry 4.0 transformations.

Comparison Table

| Feature | Digital Twin Consulting | Smart Manufacturing Consulting |

|---|---|---|

| Definition | Develops virtual replicas of physical assets for simulation and optimization. | Integrates smart technologies to automate and enhance manufacturing processes. |

| Primary Focus | Asset performance, predictive maintenance, and real-time monitoring. | Process automation, supply chain optimization, and production efficiency. |

| Key Technologies | IoT sensors, simulation software, cloud computing, AR/VR. | AI, robotics, IoT, data analytics, machine learning. |

| Industry Applications | Manufacturing, energy, aerospace, healthcare. | Automotive, electronics, consumer goods, aerospace. |

| Consulting Benefits | Improved asset lifecycle management, reduced downtime, cost savings. | Increased production speed, quality enhancement, reduced operational costs. |

| Implementation Duration | Medium to long term (3-12 months). | Short to medium term (1-6 months). |

| Typical Clients | Large enterprises with complex assets. | Manufacturers seeking operational efficiency. |

Which is better?

Digital twin consulting offers enhanced visualization and real-time simulation of physical assets, allowing businesses to predict outcomes and optimize operations with high precision. Smart manufacturing consulting focuses on integrating IoT, AI, and automation technologies to improve production efficiency and reduce costs across the manufacturing process. The better option depends on a company's specific needs: digital twin is ideal for detailed asset management and process simulation, while smart manufacturing provides comprehensive solutions for digitizing and automating production workflows.

Connection

Digital twin consulting and smart manufacturing consulting collaborate by integrating real-time digital replicas of physical assets to optimize manufacturing processes. Leveraging data analytics and simulation, digital twins provide actionable insights that enhance smart manufacturing strategies for improved efficiency and reduced downtime. This synergy drives predictive maintenance, process automation, and quality control within Industry 4.0 frameworks.

Key Terms

**Smart manufacturing consulting:**

Smart manufacturing consulting emphasizes integrating advanced technologies like IoT, AI, and automation to optimize production processes, reduce operational costs, and enhance product quality. Consultants analyze data-driven insights and implement smart factory solutions that improve efficiency and scalability across manufacturing systems. Discover how smart manufacturing consulting can transform your operations and drive innovation.

Industrial IoT (IIoT)

Smart manufacturing consulting emphasizes optimizing production processes using Industrial IoT (IIoT) technologies to enhance efficiency, reduce downtime, and enable real-time data analytics across factory operations. Digital twin consulting specializes in creating virtual replicas of physical assets and systems through IIoT sensors, facilitating predictive maintenance, performance simulation, and process optimization. Explore how integrating these consulting approaches can drive Industry 4.0 transformation in your manufacturing operations.

Advanced analytics

Smart manufacturing consulting integrates advanced analytics to optimize production processes, enhance predictive maintenance, and improve supply chain efficiency through real-time data insights. Digital twin consulting leverages advanced analytics to create virtual replicas of physical assets, enabling detailed simulations, performance monitoring, and scenario testing to drive operational excellence. Explore how advanced analytics in these consulting services can transform your industrial strategies and yield data-driven decisions.

Source and External Links

Industry 4.0 and Smart Manufacturing Consulting - Grantek - Grantek offers expert consulting on Industry 4.0 technologies, focusing on a holistic approach to design and manage smart manufacturing operations to enable data-driven decisions and market opportunities.

Smart Manufacturing | Rockwell Automation | US - Rockwell Automation supports digital transformation with services and products to optimize productivity, quality, risk management, and sustainability in smart manufacturing.

Smart Factory: PwC - PwC's smart factory consulting combines digital and manufacturing capabilities using a value-first approach to enhance flexibility, efficiency, and reduce interruptions through analytics and essential Industry 4.0 technologies.

dowidth.com

dowidth.com