Digital twin strategy leverages advanced simulations and real-time data to optimize asset performance and predict maintenance needs, driving innovation across industries. Operational excellence focuses on streamlining processes, reducing waste, and improving efficiency to enhance overall organizational performance. Explore how integrating digital twin technology with operational excellence can transform your business outcomes.

Why it is important

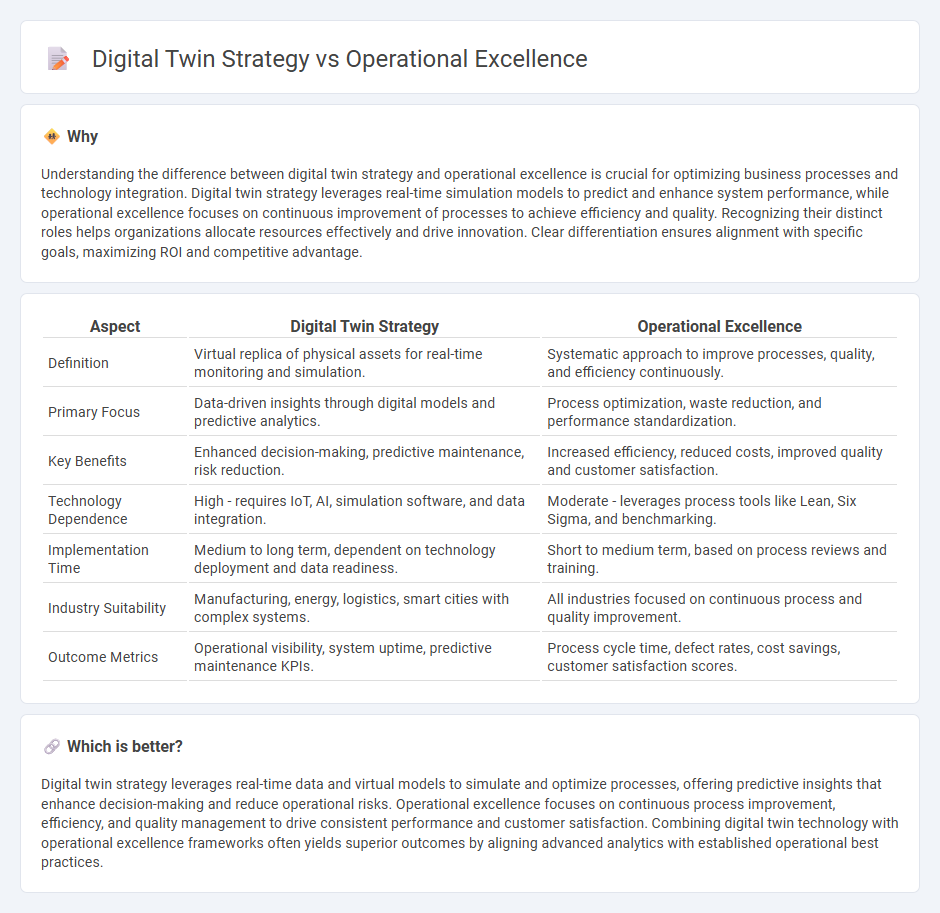

Understanding the difference between digital twin strategy and operational excellence is crucial for optimizing business processes and technology integration. Digital twin strategy leverages real-time simulation models to predict and enhance system performance, while operational excellence focuses on continuous improvement of processes to achieve efficiency and quality. Recognizing their distinct roles helps organizations allocate resources effectively and drive innovation. Clear differentiation ensures alignment with specific goals, maximizing ROI and competitive advantage.

Comparison Table

| Aspect | Digital Twin Strategy | Operational Excellence |

|---|---|---|

| Definition | Virtual replica of physical assets for real-time monitoring and simulation. | Systematic approach to improve processes, quality, and efficiency continuously. |

| Primary Focus | Data-driven insights through digital models and predictive analytics. | Process optimization, waste reduction, and performance standardization. |

| Key Benefits | Enhanced decision-making, predictive maintenance, risk reduction. | Increased efficiency, reduced costs, improved quality and customer satisfaction. |

| Technology Dependence | High - requires IoT, AI, simulation software, and data integration. | Moderate - leverages process tools like Lean, Six Sigma, and benchmarking. |

| Implementation Time | Medium to long term, dependent on technology deployment and data readiness. | Short to medium term, based on process reviews and training. |

| Industry Suitability | Manufacturing, energy, logistics, smart cities with complex systems. | All industries focused on continuous process and quality improvement. |

| Outcome Metrics | Operational visibility, system uptime, predictive maintenance KPIs. | Process cycle time, defect rates, cost savings, customer satisfaction scores. |

Which is better?

Digital twin strategy leverages real-time data and virtual models to simulate and optimize processes, offering predictive insights that enhance decision-making and reduce operational risks. Operational excellence focuses on continuous process improvement, efficiency, and quality management to drive consistent performance and customer satisfaction. Combining digital twin technology with operational excellence frameworks often yields superior outcomes by aligning advanced analytics with established operational best practices.

Connection

Digital twin strategy enhances operational excellence by providing real-time simulations and data analytics that optimize process efficiency and reduce downtime. Implementing digital twins enables predictive maintenance and informed decision-making, directly improving key performance indicators such as asset utilization and throughput. Enterprises adopting this approach achieve continuous improvement and operational agility through accurate virtual modeling of physical systems.

Key Terms

Process Optimization

Operational excellence drives continuous improvement in manufacturing through lean practices and data analytics, enhancing efficiency and reducing waste. Digital twin strategy leverages real-time simulations of physical processes to predict outcomes and optimize performance dynamically. Discover how integrating these approaches can revolutionize your process optimization efforts.

Real-time Data Integration

Operational excellence leverages real-time data integration to optimize processes, reduce downtime, and boost productivity through continuous monitoring and automated decision-making. Digital twin strategy uses real-time data integration to create dynamic, virtual replicas of physical assets, enabling predictive maintenance and scenario simulation for enhanced operational insights. Explore how integrating real-time data drives both operational excellence and digital twin innovations to transform your business performance.

Performance Simulation

Operational excellence emphasizes continuous improvement in processes to enhance efficiency and reduce costs, leveraging data analytics and real-time monitoring. Digital twin strategy focuses on creating virtual replicas of physical assets to simulate performance, predict issues, and optimize decision-making through advanced performance simulation. Explore how integrating operational excellence with digital twin technology can drive superior performance outcomes.

Source and External Links

Continuous Improvement vs Operational Excellence - Operational excellence is a strategic management philosophy focused on streamlining production, eliminating waste, optimizing resources, and delivering high-quality customer value, representing a long-term, ongoing pursuit rather than a passing trend.

What is Operational Excellence? 2025 Guide - Operational excellence means outperforming competition by adopting core principles including customer focus, continuous improvement, lean thinking, and process standardization to foster efficiency, innovation, and superior customer experiences.

Operational excellence - Operational excellence involves systematic implementation of principles and tools such as Juran's Model, emphasizing integrated management systems, operational discipline, leadership involvement, change infrastructure, and enhancing business process agility.

dowidth.com

dowidth.com