Digital twin simulation offers a dynamic, real-time virtual replica of physical systems, enabling continuous monitoring and predictive maintenance, while Computational Fluid Dynamics (CFD) focuses on analyzing fluid flow and heat transfer through complex calculations and modeling. By integrating digital twin technology with CFD, businesses can enhance operational efficiency, reduce downtime, and optimize system designs with higher precision. Explore how combining these advanced consulting solutions can transform your engineering and operational strategies.

Why it is important

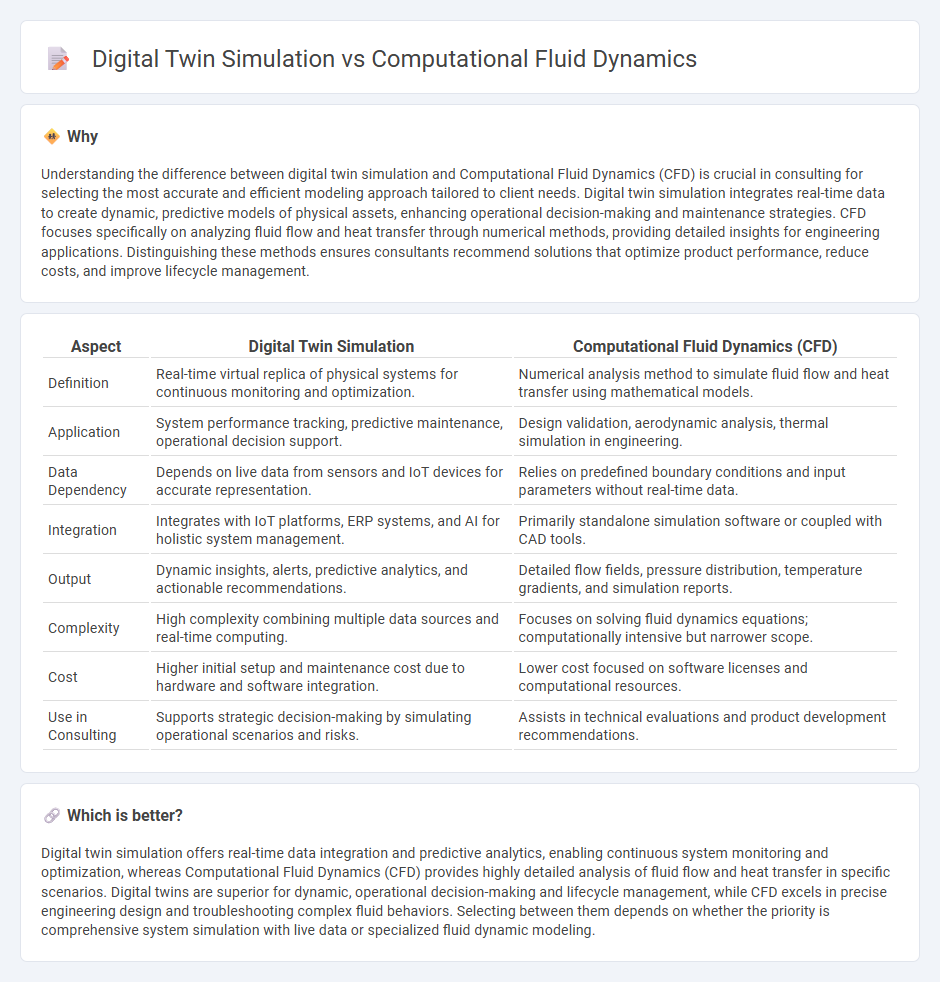

Understanding the difference between digital twin simulation and Computational Fluid Dynamics (CFD) is crucial in consulting for selecting the most accurate and efficient modeling approach tailored to client needs. Digital twin simulation integrates real-time data to create dynamic, predictive models of physical assets, enhancing operational decision-making and maintenance strategies. CFD focuses specifically on analyzing fluid flow and heat transfer through numerical methods, providing detailed insights for engineering applications. Distinguishing these methods ensures consultants recommend solutions that optimize product performance, reduce costs, and improve lifecycle management.

Comparison Table

| Aspect | Digital Twin Simulation | Computational Fluid Dynamics (CFD) |

|---|---|---|

| Definition | Real-time virtual replica of physical systems for continuous monitoring and optimization. | Numerical analysis method to simulate fluid flow and heat transfer using mathematical models. |

| Application | System performance tracking, predictive maintenance, operational decision support. | Design validation, aerodynamic analysis, thermal simulation in engineering. |

| Data Dependency | Depends on live data from sensors and IoT devices for accurate representation. | Relies on predefined boundary conditions and input parameters without real-time data. |

| Integration | Integrates with IoT platforms, ERP systems, and AI for holistic system management. | Primarily standalone simulation software or coupled with CAD tools. |

| Output | Dynamic insights, alerts, predictive analytics, and actionable recommendations. | Detailed flow fields, pressure distribution, temperature gradients, and simulation reports. |

| Complexity | High complexity combining multiple data sources and real-time computing. | Focuses on solving fluid dynamics equations; computationally intensive but narrower scope. |

| Cost | Higher initial setup and maintenance cost due to hardware and software integration. | Lower cost focused on software licenses and computational resources. |

| Use in Consulting | Supports strategic decision-making by simulating operational scenarios and risks. | Assists in technical evaluations and product development recommendations. |

Which is better?

Digital twin simulation offers real-time data integration and predictive analytics, enabling continuous system monitoring and optimization, whereas Computational Fluid Dynamics (CFD) provides highly detailed analysis of fluid flow and heat transfer in specific scenarios. Digital twins are superior for dynamic, operational decision-making and lifecycle management, while CFD excels in precise engineering design and troubleshooting complex fluid behaviors. Selecting between them depends on whether the priority is comprehensive system simulation with live data or specialized fluid dynamic modeling.

Connection

Digital twin simulation leverages computational fluid dynamics (CFD) to create accurate, real-time models of fluid behavior in physical systems, enhancing predictive maintenance and operational efficiency. CFD provides detailed analysis of fluid flow, heat transfer, and related phenomena, which digital twins integrate to simulate and optimize complex processes across industries. By combining these technologies, consulting firms deliver data-driven solutions that improve performance, reduce costs, and enable proactive decision-making.

Key Terms

Fluid Flow Modeling

Computational Fluid Dynamics (CFD) offers detailed fluid flow modeling by solving numerical equations that describe fluid behavior, enabling precise analysis of velocity, pressure, and turbulence in complex systems. Digital twin simulation integrates real-time sensor data with CFD models, enhancing predictive accuracy and operational optimization by continuously updating the virtual replica of the physical system. Explore more about how combining CFD and digital twins revolutionizes fluid flow analysis and system performance.

Real-time Data Integration

Computational Fluid Dynamics (CFD) provides detailed fluid flow analysis using numerical methods, but often lacks real-time data updates during simulation. Digital twin simulation integrates real-time sensor data to continuously update and optimize models, enabling dynamic and adaptive analysis of fluid systems. Explore how real-time data integration transforms simulation accuracy and operational efficiency.

Virtual Prototype

Computational Fluid Dynamics (CFD) provides detailed analysis of fluid flow and heat transfer within virtual prototypes, enabling precise evaluation of aerodynamic and thermal performance in engineering designs. Digital twin simulation integrates CFD results with real-time sensor data and system behaviors to create dynamic, predictive models that replicate real-world operations and lifecycle conditions. Explore how combining CFD with digital twin technology enhances virtual prototyping and accelerates product development.

Source and External Links

What is Computational Fluid Dynamics (CFD)? - CFD is a branch of fluid mechanics using computational methods to model fluid flow and heat transfer, solving the Navier-Stokes equations to simulate complex scenarios across aerospace, automotive, and environmental engineering fields.

Computational fluid dynamics (CFD) simulation - CFD applies numerical methods and computing to solve fluid dynamics problems based on fundamental physics and the Navier-Stokes equations, often supplementing or replacing experimental approaches in engineering design.

What is Computational Fluid Dynamics (CFD)? - CFD involves identifying a fluid flow domain, discretizing it into a computational mesh, and solving fluid governing equations on it, addressing complex multiphysics interactions and nonlinear fluid behavior using high-performance computing.

dowidth.com

dowidth.com