Digital twin strategy leverages real-time virtual models to optimize operations, enhance decision-making, and predict system behaviors in manufacturing, construction, and urban planning. Lean transformation focuses on eliminating waste, improving process efficiency, and fostering a culture of continuous improvement across organizational workflows. Discover how integrating digital twin technology with lean principles can drive unprecedented operational agility and value creation.

Why it is important

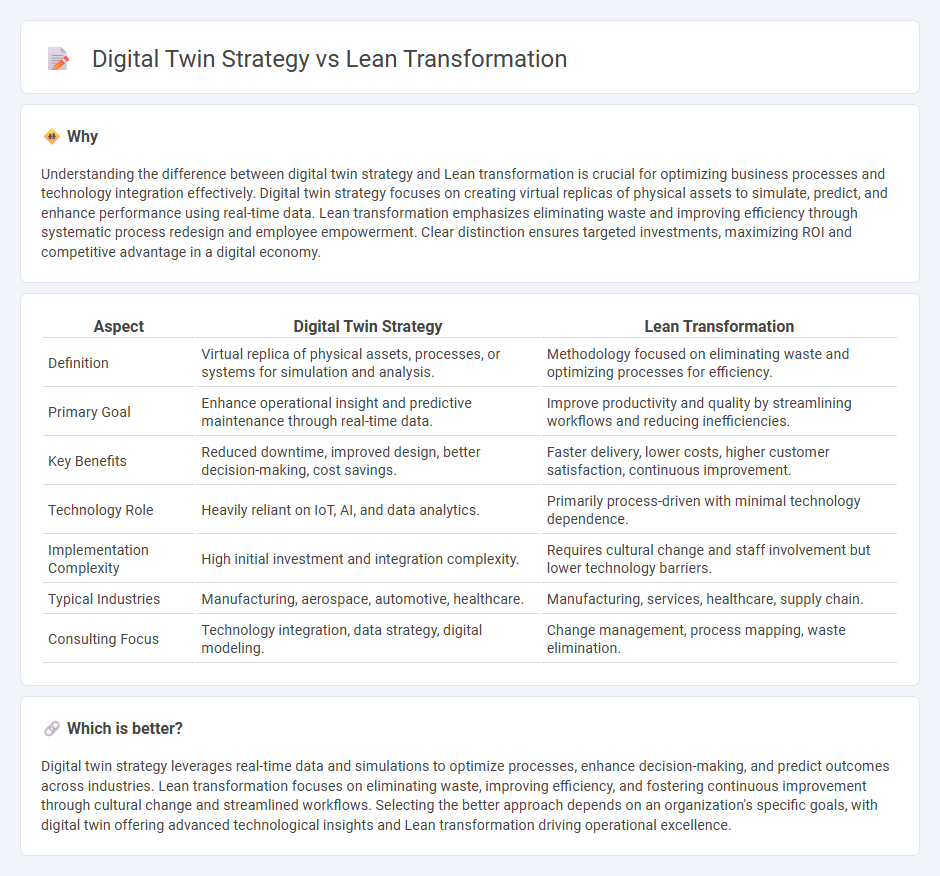

Understanding the difference between digital twin strategy and Lean transformation is crucial for optimizing business processes and technology integration effectively. Digital twin strategy focuses on creating virtual replicas of physical assets to simulate, predict, and enhance performance using real-time data. Lean transformation emphasizes eliminating waste and improving efficiency through systematic process redesign and employee empowerment. Clear distinction ensures targeted investments, maximizing ROI and competitive advantage in a digital economy.

Comparison Table

| Aspect | Digital Twin Strategy | Lean Transformation |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems for simulation and analysis. | Methodology focused on eliminating waste and optimizing processes for efficiency. |

| Primary Goal | Enhance operational insight and predictive maintenance through real-time data. | Improve productivity and quality by streamlining workflows and reducing inefficiencies. |

| Key Benefits | Reduced downtime, improved design, better decision-making, cost savings. | Faster delivery, lower costs, higher customer satisfaction, continuous improvement. |

| Technology Role | Heavily reliant on IoT, AI, and data analytics. | Primarily process-driven with minimal technology dependence. |

| Implementation Complexity | High initial investment and integration complexity. | Requires cultural change and staff involvement but lower technology barriers. |

| Typical Industries | Manufacturing, aerospace, automotive, healthcare. | Manufacturing, services, healthcare, supply chain. |

| Consulting Focus | Technology integration, data strategy, digital modeling. | Change management, process mapping, waste elimination. |

Which is better?

Digital twin strategy leverages real-time data and simulations to optimize processes, enhance decision-making, and predict outcomes across industries. Lean transformation focuses on eliminating waste, improving efficiency, and fostering continuous improvement through cultural change and streamlined workflows. Selecting the better approach depends on an organization's specific goals, with digital twin offering advanced technological insights and Lean transformation driving operational excellence.

Connection

Digital twin strategy leverages real-time virtual models to simulate and optimize operational processes, directly complementing Lean transformation's focus on eliminating waste and enhancing efficiency. Integrating digital twins enables continuous monitoring and rapid iteration, which aligns with Lean principles by driving data-driven decision-making and process improvements. This synergy accelerates organizational agility and operational excellence in consulting engagements.

Key Terms

Value Stream Mapping

Value Stream Mapping (VSM) is pivotal in both Lean transformation and digital twin strategies for enhancing process efficiency and eliminating waste. Lean transformation leverages VSM to visually identify bottlenecks and non-value-added activities in physical workflows, driving continuous improvement. Explore how integrating VSM within digital twin models can simulate changes digitally to optimize entire value streams before implementation.

Simulation Modeling

Lean transformation emphasizes waste reduction and process efficiency by streamlining workflows and enhancing value delivery. Digital twin strategy leverages advanced simulation modeling to create real-time virtual replicas of physical assets, enabling predictive maintenance and optimized performance. Explore how combining lean principles with digital twin simulation can revolutionize operational excellence.

Continuous Improvement

Lean transformation emphasizes eliminating waste and optimizing processes through continuous improvement cycles such as Kaizen and PDCA, fostering a culture of efficiency and employee engagement. Digital twin strategy leverages real-time data and virtual simulations to monitor, analyze, and predict operational performance, enabling proactive decision-making and rapid iteration. Explore how integrating Lean principles with digital twin technology can accelerate continuous improvement and maximize organizational value.

Source and External Links

The Power of Lean Transformation: A Guide to Manufacturing Excellence - Lean transformation focuses on optimizing processes, eliminating non-value-added activities, and fostering continuous improvement through steps such as assessment, leadership commitment, employee training, value stream mapping, and kaizen events for sustained efficiency gains.

What is Lean Transformation, and how does it help your business? - Lean transformation involves strategic, tactical, and operational improvements guided by a roadmap of evaluation, initiation, training, tooling, value stream mapping, and continuous improvement to create more value for customers.

What is Lean Transformation and Why is It Important? - Planview Blog - Lean transformation is driven by a value-driven purpose to consistently deliver more value with less waste, emphasizing continuous improvement, capability development, and lean management systems for sustainable organizational change.

dowidth.com

dowidth.com