Design sprint facilitation accelerates innovation by condensing product design and user feedback into a focused, time-boxed workshop, fostering rapid prototyping and decision-making. Lean process improvement emphasizes eliminating waste and enhancing operational efficiency through continuous, data-driven analysis and employee empowerment. Explore how each methodology can transform your business by streamlining innovation or optimizing workflows.

Why it is important

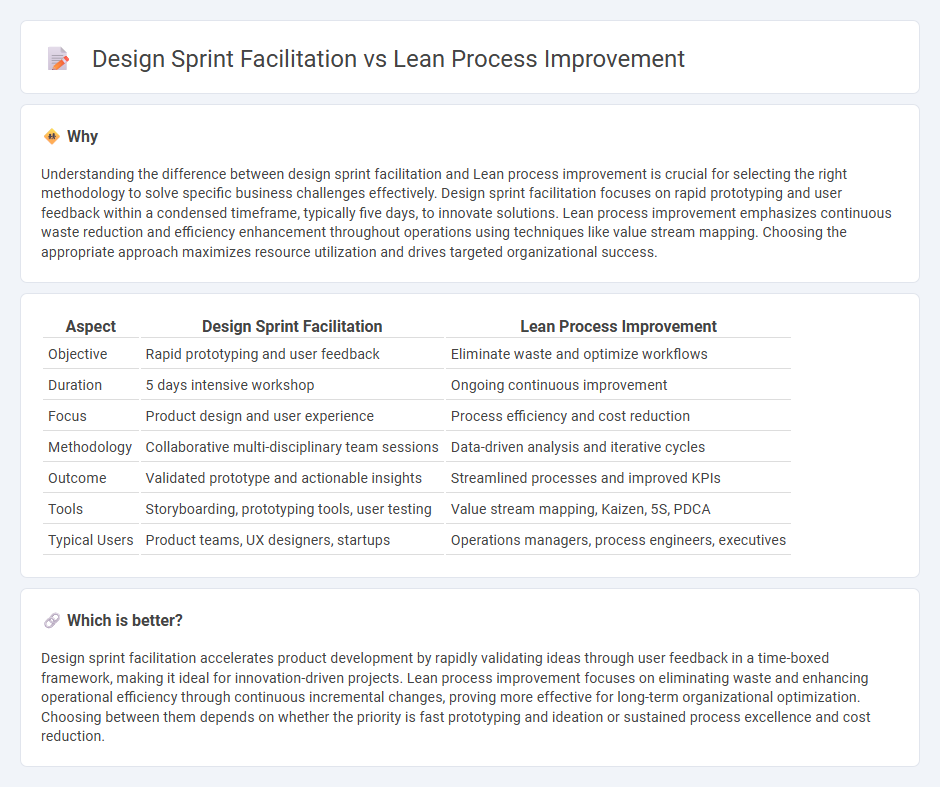

Understanding the difference between design sprint facilitation and Lean process improvement is crucial for selecting the right methodology to solve specific business challenges effectively. Design sprint facilitation focuses on rapid prototyping and user feedback within a condensed timeframe, typically five days, to innovate solutions. Lean process improvement emphasizes continuous waste reduction and efficiency enhancement throughout operations using techniques like value stream mapping. Choosing the appropriate approach maximizes resource utilization and drives targeted organizational success.

Comparison Table

| Aspect | Design Sprint Facilitation | Lean Process Improvement |

|---|---|---|

| Objective | Rapid prototyping and user feedback | Eliminate waste and optimize workflows |

| Duration | 5 days intensive workshop | Ongoing continuous improvement |

| Focus | Product design and user experience | Process efficiency and cost reduction |

| Methodology | Collaborative multi-disciplinary team sessions | Data-driven analysis and iterative cycles |

| Outcome | Validated prototype and actionable insights | Streamlined processes and improved KPIs |

| Tools | Storyboarding, prototyping tools, user testing | Value stream mapping, Kaizen, 5S, PDCA |

| Typical Users | Product teams, UX designers, startups | Operations managers, process engineers, executives |

Which is better?

Design sprint facilitation accelerates product development by rapidly validating ideas through user feedback in a time-boxed framework, making it ideal for innovation-driven projects. Lean process improvement focuses on eliminating waste and enhancing operational efficiency through continuous incremental changes, proving more effective for long-term organizational optimization. Choosing between them depends on whether the priority is fast prototyping and ideation or sustained process excellence and cost reduction.

Connection

Design sprint facilitation accelerates problem-solving by rapidly prototyping and testing ideas within a focused timeframe, directly supporting Lean process improvement goals of eliminating waste and enhancing value delivery. Both methodologies emphasize iterative development, cross-functional collaboration, and data-driven decision-making to optimize workflows and customer outcomes. Integrating design sprint facilitation into Lean process improvement frameworks drives innovation while maintaining operational efficiency and continuous improvement.

Key Terms

Value Stream Mapping

Lean process improvement emphasizes identifying and eliminating waste within value streams to enhance efficiency and increase customer value, with Value Stream Mapping (VSM) as a core tool for visualizing workflows and pinpointing bottlenecks. Design sprint facilitation incorporates VSM to rapidly prototype and test solutions, aligning multi-disciplinary teams on user-centric innovations within condensed timeframes. Explore how integrating Lean's strategic clarity with design sprints' agile execution can transform your value stream optimization efforts.

Rapid Prototyping

Lean process improvement emphasizes eliminating waste and enhancing workflow efficiency through continuous iterations, leading to progressive product refinement. Design sprint facilitation concentrates on rapid prototyping within a structured timeframe, enabling swift validation of ideas and user feedback integration. Explore the contrasting approaches to rapid prototyping in Lean and design sprints for optimized innovation outcomes.

Continuous Improvement

Lean process improvement emphasizes eliminating waste and optimizing workflows through iterative cycles like Plan-Do-Check-Act to drive continuous operational enhancements. Design sprint facilitation accelerates product development and innovation by condensing user-centered problem solving into a time-boxed, collaborative workshop format. Discover how integrating both methods can maximize efficiency and innovation in your organization.

Source and External Links

7 Lean Process Improvement Steps for Successful Optimization - Outlines seven practical steps to identify waste, engage employees, and implement solutions for continuous process optimization.

Lean Process Improvement [What is it & How to Implement] - Atlassian - Describes how to apply Lean principles by identifying improvement areas, using techniques like Kanban and the 5 Whys, and focusing on value-added activities.

3 Key Concepts of Lean Process Improvement - Planview - Highlights the use of Kanban and WIP limits to visualize workflows, reduce bottlenecks, and enhance team collaboration for sustained improvement.

dowidth.com

dowidth.com