Agile operating models emphasize iterative development, flexibility, and customer collaboration, enabling organizations to respond swiftly to market changes and evolving requirements. Lean operating models focus on eliminating waste, optimizing processes, and maximizing value through continuous improvement and efficiency. Explore the key differences and advantages of Agile versus Lean operating models to determine the best fit for your business strategy.

Why it is important

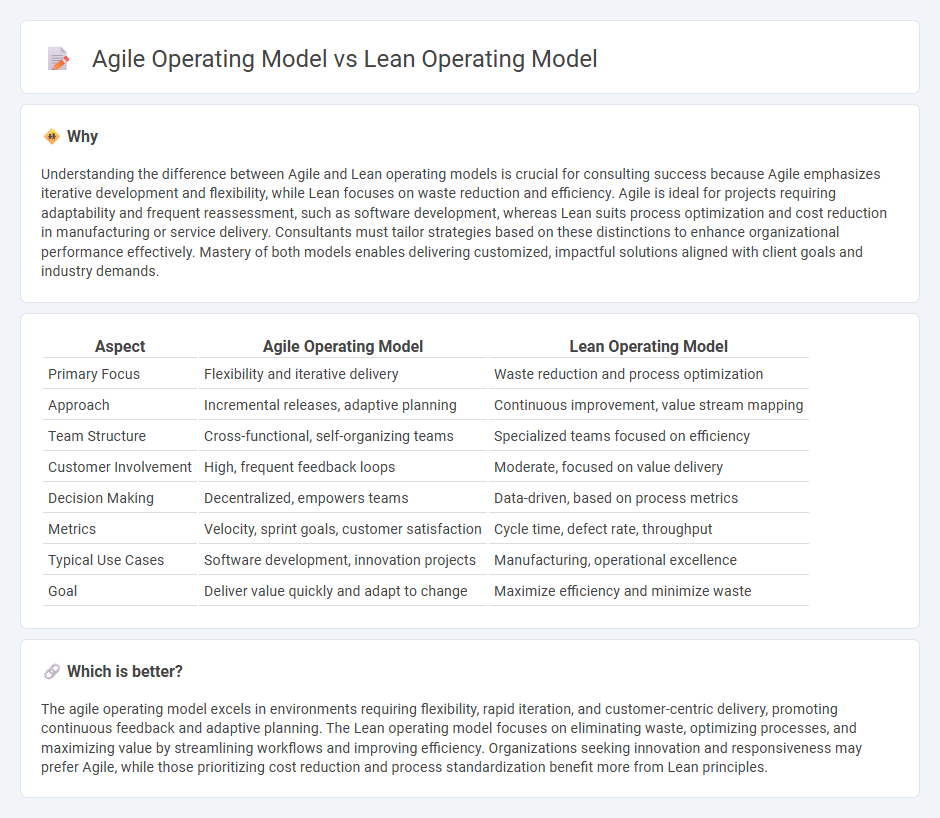

Understanding the difference between Agile and Lean operating models is crucial for consulting success because Agile emphasizes iterative development and flexibility, while Lean focuses on waste reduction and efficiency. Agile is ideal for projects requiring adaptability and frequent reassessment, such as software development, whereas Lean suits process optimization and cost reduction in manufacturing or service delivery. Consultants must tailor strategies based on these distinctions to enhance organizational performance effectively. Mastery of both models enables delivering customized, impactful solutions aligned with client goals and industry demands.

Comparison Table

| Aspect | Agile Operating Model | Lean Operating Model |

|---|---|---|

| Primary Focus | Flexibility and iterative delivery | Waste reduction and process optimization |

| Approach | Incremental releases, adaptive planning | Continuous improvement, value stream mapping |

| Team Structure | Cross-functional, self-organizing teams | Specialized teams focused on efficiency |

| Customer Involvement | High, frequent feedback loops | Moderate, focused on value delivery |

| Decision Making | Decentralized, empowers teams | Data-driven, based on process metrics |

| Metrics | Velocity, sprint goals, customer satisfaction | Cycle time, defect rate, throughput |

| Typical Use Cases | Software development, innovation projects | Manufacturing, operational excellence |

| Goal | Deliver value quickly and adapt to change | Maximize efficiency and minimize waste |

Which is better?

The agile operating model excels in environments requiring flexibility, rapid iteration, and customer-centric delivery, promoting continuous feedback and adaptive planning. The Lean operating model focuses on eliminating waste, optimizing processes, and maximizing value by streamlining workflows and improving efficiency. Organizations seeking innovation and responsiveness may prefer Agile, while those prioritizing cost reduction and process standardization benefit more from Lean principles.

Connection

The Agile operating model and Lean operating model are connected through their shared focus on maximizing value while minimizing waste in business processes. Agile emphasizes iterative development and customer feedback to enhance flexibility and responsiveness, whereas Lean concentrates on streamlining operations to eliminate inefficiencies. Integrating these methodologies enables organizations to improve speed, quality, and adaptability in consulting engagements and project delivery.

Key Terms

Value Stream Mapping (Lean)

Value Stream Mapping in Lean operating models emphasizes identifying and eliminating waste across processes to enhance efficiency and deliver maximum customer value by streamlining workflows. Agile operating models prioritize iterative development and flexibility, focusing on adaptability and continuous feedback rather than detailed process mapping. Explore how these methodologies can transform operational performance and customer satisfaction.

Iterative Development (Agile)

Lean operating models emphasize eliminating waste and streamlining processes to maximize value delivery with minimal resources, while agile operating models prioritize iterative development cycles that foster continuous feedback and adaptability. Agile methods break down projects into small, manageable increments, enabling teams to rapidly respond to changing customer needs and market conditions. Explore how integrating iterative development enhances responsiveness and efficiency in modern operating models.

Continuous Improvement (both)

The Lean operating model emphasizes continuous improvement through waste reduction, value stream mapping, and empowering employees to identify inefficiencies in processes. The Agile operating model drives continuous improvement by fostering iterative development, regular feedback loops, and adaptable team collaboration to enhance product quality and responsiveness. Explore how integrating Lean and Agile principles can optimize continuous improvement and drive operational excellence in your organization.

Source and External Links

Developing a Lean Operations Model for Maximum Efficiency - A lean operating model is centered on three core principles: Clarity of Purpose, Streamlined Execution, and Focused Communication, aiming to maximize impact with minimal waste by aligning teams around what truly moves the business forward.

Lean Operations and How You Can Use It to Save Money - Beekeeper - Lean operations is a minimalist business strategy driven by doing more with less, focusing on continuous improvement to eliminate waste and improve operational excellence through optimized processes and workforce.

What is a Lean Business? - Planview - A lean business model maximizes value and minimizes waste by optimizing the entire value stream, building quality in early, delivering fast in increments, and respecting people, ensuring continuous learning and agile decision-making.

dowidth.com

dowidth.com