Operational Excellence Mapping focuses on aligning processes with strategic objectives to enhance efficiency, quality, and customer satisfaction, leveraging data-driven insights for continuous improvement. Lean Mapping targets waste reduction by visualizing workflows and identifying non-value-added activities, primarily using Value Stream Mapping to streamline production and service delivery. Explore further to understand how these methodologies can transform your organizational performance.

Why it is important

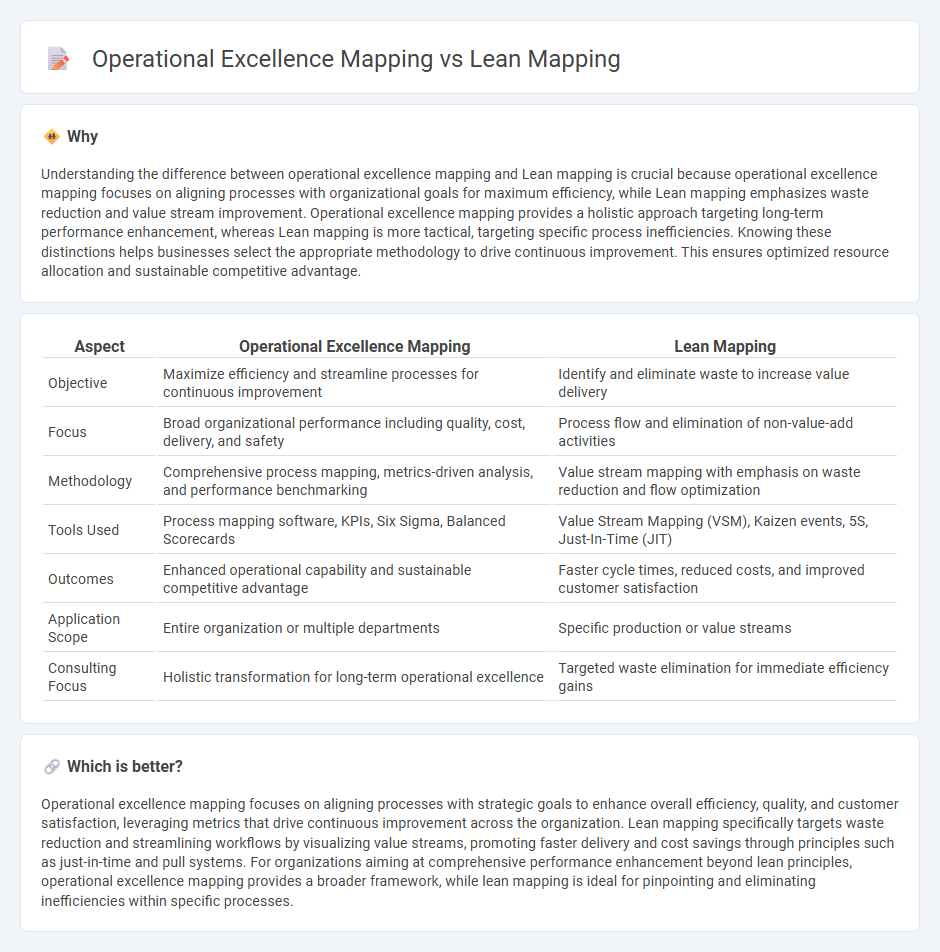

Understanding the difference between operational excellence mapping and Lean mapping is crucial because operational excellence mapping focuses on aligning processes with organizational goals for maximum efficiency, while Lean mapping emphasizes waste reduction and value stream improvement. Operational excellence mapping provides a holistic approach targeting long-term performance enhancement, whereas Lean mapping is more tactical, targeting specific process inefficiencies. Knowing these distinctions helps businesses select the appropriate methodology to drive continuous improvement. This ensures optimized resource allocation and sustainable competitive advantage.

Comparison Table

| Aspect | Operational Excellence Mapping | Lean Mapping |

|---|---|---|

| Objective | Maximize efficiency and streamline processes for continuous improvement | Identify and eliminate waste to increase value delivery |

| Focus | Broad organizational performance including quality, cost, delivery, and safety | Process flow and elimination of non-value-add activities |

| Methodology | Comprehensive process mapping, metrics-driven analysis, and performance benchmarking | Value stream mapping with emphasis on waste reduction and flow optimization |

| Tools Used | Process mapping software, KPIs, Six Sigma, Balanced Scorecards | Value Stream Mapping (VSM), Kaizen events, 5S, Just-In-Time (JIT) |

| Outcomes | Enhanced operational capability and sustainable competitive advantage | Faster cycle times, reduced costs, and improved customer satisfaction |

| Application Scope | Entire organization or multiple departments | Specific production or value streams |

| Consulting Focus | Holistic transformation for long-term operational excellence | Targeted waste elimination for immediate efficiency gains |

Which is better?

Operational excellence mapping focuses on aligning processes with strategic goals to enhance overall efficiency, quality, and customer satisfaction, leveraging metrics that drive continuous improvement across the organization. Lean mapping specifically targets waste reduction and streamlining workflows by visualizing value streams, promoting faster delivery and cost savings through principles such as just-in-time and pull systems. For organizations aiming at comprehensive performance enhancement beyond lean principles, operational excellence mapping provides a broader framework, while lean mapping is ideal for pinpointing and eliminating inefficiencies within specific processes.

Connection

Operational excellence mapping and Lean Mapping are closely connected through their shared focus on improving business processes by identifying inefficiencies and eliminating waste. Both methodologies use visual tools to analyze workflows, streamline operations, and enhance value delivery to customers. Implementing Lean Mapping within operational excellence frameworks drives continuous improvement and operational efficiency across organizations.

Key Terms

Value Stream Mapping

Value Stream Mapping (VSM) is a core tool in Lean Mapping focused on visualizing and analyzing the flow of materials and information to identify and eliminate waste within processes. Operational excellence mapping integrates VSM with broader strategic and performance metrics, aiming to enhance overall organizational efficiency, quality, and customer satisfaction. Explore the distinctions and applications of Lean and operational excellence mapping to optimize your value streams effectively.

Process Improvement

Lean mapping emphasizes the identification and elimination of waste within processes to enhance flow and reduce cycle times, targeting value creation from the customer's perspective. Operational excellence mapping integrates lean principles with strategic goals, risk management, and performance metrics to drive sustainable process improvements and organizational alignment. Explore how combining these approaches can optimize efficiency and achieve superior operational results.

Waste Elimination

Lean Mapping targets identifying and eliminating the seven types of waste to streamline processes and increase value delivery by emphasizing value stream visualization and flow efficiency. Operational Excellence Mapping expands the scope by integrating waste elimination with strategic goals, continuous improvement practices, and performance metrics to ensure sustainable operational improvements across the organization. Explore the detailed methodologies and benefits of both approaches to enhance your organization's waste elimination strategies.

Source and External Links

What is Lean Process Mapping and the Best Tool to Create it - Lean process mapping is the creation of a process map focused on reducing waste, mainly targeting time efficiency between activities to optimize processes in terms of time, cost, and quality through continuous improvement.

Value Stream Mapping Overview - Lean Enterprise Institute - Value-stream mapping is a lean tool diagramming all steps in material and information flows from order to delivery, highlighting process flow times and efficiency for lean transformation.

Process Mapping | Lean Construction Institute - Lean process mapping involves visually defining process steps clearly, starting from identification to continuous improvement, to standardize and optimize work processes within teams.

dowidth.com

dowidth.com