Digital twin consulting focuses on creating precise virtual replicas of physical assets to optimize performance and enable predictive maintenance, while Industry 4.0 consulting encompasses a broader approach integrating IoT, automation, and data analytics to transform entire manufacturing processes. Companies leveraging digital twin technology gain detailed, real-time insights for product lifecycle management, whereas Industry 4.0 strategies drive overall smart factory implementation and operational efficiency. Discover how tailored consulting services can accelerate your digital transformation journey.

Why it is important

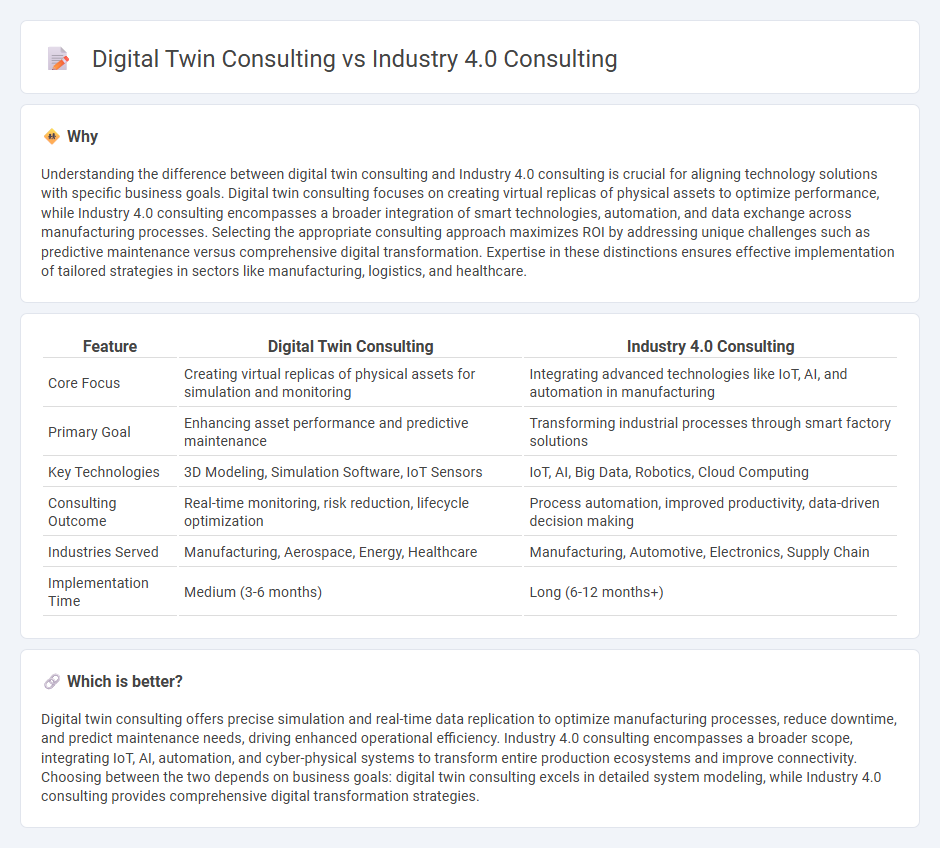

Understanding the difference between digital twin consulting and Industry 4.0 consulting is crucial for aligning technology solutions with specific business goals. Digital twin consulting focuses on creating virtual replicas of physical assets to optimize performance, while Industry 4.0 consulting encompasses a broader integration of smart technologies, automation, and data exchange across manufacturing processes. Selecting the appropriate consulting approach maximizes ROI by addressing unique challenges such as predictive maintenance versus comprehensive digital transformation. Expertise in these distinctions ensures effective implementation of tailored strategies in sectors like manufacturing, logistics, and healthcare.

Comparison Table

| Feature | Digital Twin Consulting | Industry 4.0 Consulting |

|---|---|---|

| Core Focus | Creating virtual replicas of physical assets for simulation and monitoring | Integrating advanced technologies like IoT, AI, and automation in manufacturing |

| Primary Goal | Enhancing asset performance and predictive maintenance | Transforming industrial processes through smart factory solutions |

| Key Technologies | 3D Modeling, Simulation Software, IoT Sensors | IoT, AI, Big Data, Robotics, Cloud Computing |

| Consulting Outcome | Real-time monitoring, risk reduction, lifecycle optimization | Process automation, improved productivity, data-driven decision making |

| Industries Served | Manufacturing, Aerospace, Energy, Healthcare | Manufacturing, Automotive, Electronics, Supply Chain |

| Implementation Time | Medium (3-6 months) | Long (6-12 months+) |

Which is better?

Digital twin consulting offers precise simulation and real-time data replication to optimize manufacturing processes, reduce downtime, and predict maintenance needs, driving enhanced operational efficiency. Industry 4.0 consulting encompasses a broader scope, integrating IoT, AI, automation, and cyber-physical systems to transform entire production ecosystems and improve connectivity. Choosing between the two depends on business goals: digital twin consulting excels in detailed system modeling, while Industry 4.0 consulting provides comprehensive digital transformation strategies.

Connection

Digital twin consulting and Industry 4.0 consulting are interconnected through their focus on leveraging advanced digital technologies to optimize industrial processes. Digital twins provide real-time virtual simulations of physical assets, enabling predictive maintenance and enhanced decision-making, which are core components of Industry 4.0 strategies. By integrating digital twin models with Industry 4.0 frameworks, organizations can achieve smart manufacturing, increased operational efficiency, and data-driven insights.

Key Terms

**Industry 4.0 consulting:**

Industry 4.0 consulting specializes in integrating advanced technologies such as IoT, AI, and automation into manufacturing and industrial processes to enhance efficiency, flexibility, and data-driven decision-making. This consulting service targets smart factory implementation, predictive maintenance, and supply chain optimization by leveraging real-time data and interconnected systems. Discover how Industry 4.0 consulting can transform your operations and drive innovation in your enterprise.

Smart Manufacturing

Industry 4.0 consulting emphasizes integrating cyber-physical systems, IoT, and data analytics to enhance overall manufacturing efficiency and agility. Digital twin consulting specifically leverages virtual replicas of physical assets to simulate processes, predict maintenance needs, and optimize production in real time. Explore how combining both approaches can revolutionize Smart Manufacturing for your enterprise.

IoT Integration

Industry 4.0 consulting emphasizes IoT integration to create smart manufacturing environments through interconnected devices and data analytics. Digital twin consulting leverages IoT data to develop virtual replicas of physical assets, enabling real-time monitoring and predictive maintenance. Explore how these consulting approaches differ in maximizing IoT potential for business innovation.

Source and External Links

Consulting 4.0: Looking beyond People into Business Sustainability - Industry 4.0 consulting embraces not only people and processes but also integrates technology and business sustainability to enable meaningful digital transformation and lasting value for companies.

How Industry 4.0 Consultants Help with Digital Transformation - Industry 4.0 consultants guide companies in adopting modern technologies like IoT, AI, and data analytics to improve manufacturing processes gradually and strategically for better decision-making and competitiveness.

Industry 4.0 Consulting - CRB Group - Industry 4.0 consulting here focuses on identifying operational gaps, developing digital roadmaps, leveraging AI, and optimizing processes to enhance productivity and facilitate digital transformation aligned with regulatory and business needs.

dowidth.com

dowidth.com