Digital Twin Simulation creates dynamic virtual replicas of physical assets or processes, enabling real-time data integration and predictive analytics for enhanced decision-making. Discrete Event Simulation models complex systems through sequences of events, focusing on operational workflows and resource allocation over time. Explore the key differences and applications to determine the best simulation approach for your consulting needs.

Why it is important

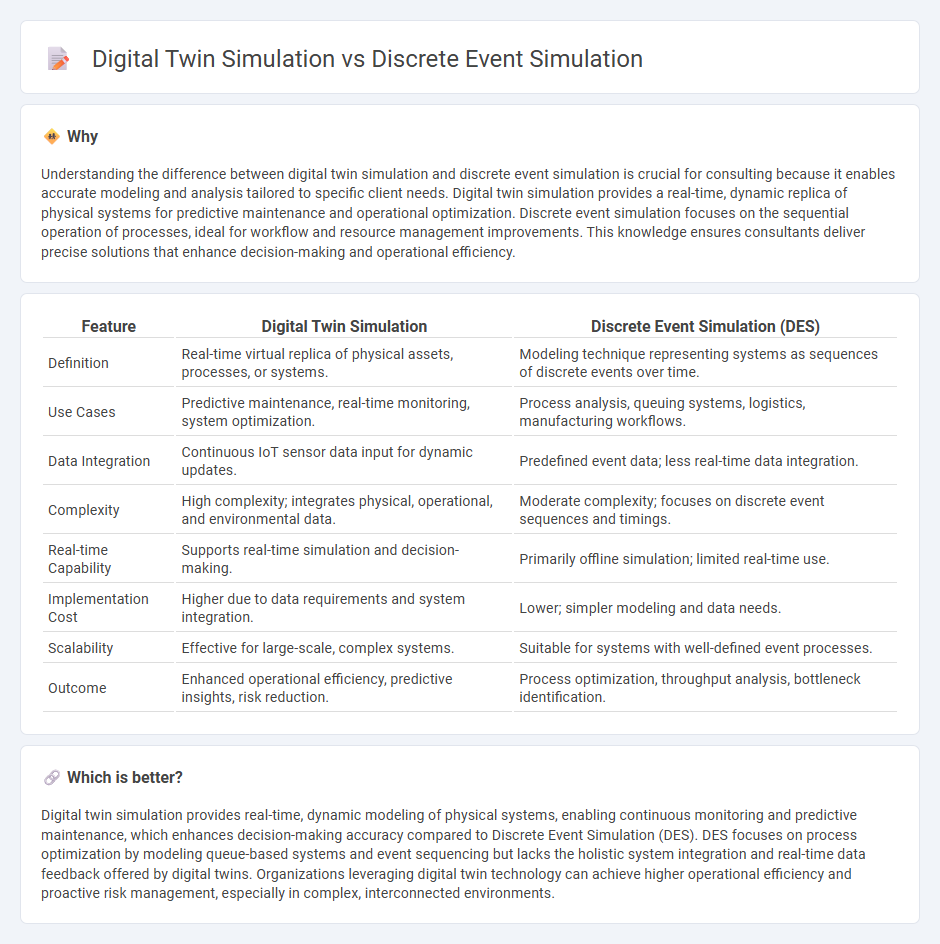

Understanding the difference between digital twin simulation and discrete event simulation is crucial for consulting because it enables accurate modeling and analysis tailored to specific client needs. Digital twin simulation provides a real-time, dynamic replica of physical systems for predictive maintenance and operational optimization. Discrete event simulation focuses on the sequential operation of processes, ideal for workflow and resource management improvements. This knowledge ensures consultants deliver precise solutions that enhance decision-making and operational efficiency.

Comparison Table

| Feature | Digital Twin Simulation | Discrete Event Simulation (DES) |

|---|---|---|

| Definition | Real-time virtual replica of physical assets, processes, or systems. | Modeling technique representing systems as sequences of discrete events over time. |

| Use Cases | Predictive maintenance, real-time monitoring, system optimization. | Process analysis, queuing systems, logistics, manufacturing workflows. |

| Data Integration | Continuous IoT sensor data input for dynamic updates. | Predefined event data; less real-time data integration. |

| Complexity | High complexity; integrates physical, operational, and environmental data. | Moderate complexity; focuses on discrete event sequences and timings. |

| Real-time Capability | Supports real-time simulation and decision-making. | Primarily offline simulation; limited real-time use. |

| Implementation Cost | Higher due to data requirements and system integration. | Lower; simpler modeling and data needs. |

| Scalability | Effective for large-scale, complex systems. | Suitable for systems with well-defined event processes. |

| Outcome | Enhanced operational efficiency, predictive insights, risk reduction. | Process optimization, throughput analysis, bottleneck identification. |

Which is better?

Digital twin simulation provides real-time, dynamic modeling of physical systems, enabling continuous monitoring and predictive maintenance, which enhances decision-making accuracy compared to Discrete Event Simulation (DES). DES focuses on process optimization by modeling queue-based systems and event sequencing but lacks the holistic system integration and real-time data feedback offered by digital twins. Organizations leveraging digital twin technology can achieve higher operational efficiency and proactive risk management, especially in complex, interconnected environments.

Connection

Digital twin simulation and Discrete Event Simulation (DES) are interconnected through their ability to model, analyze, and optimize complex systems in real-time, providing actionable insights for consulting projects. Digital twin technology creates a dynamic virtual replica of physical assets or processes, while DES focuses on simulating the operation sequences within those systems to identify bottlenecks and predict performance. Integrating these methods enables consultants to enhance decision-making accuracy, improve operational efficiency, and reduce costs by simulating multiple scenarios and visualizing system behavior under varying conditions.

Key Terms

Event-driven modeling

Discrete Event Simulation (DES) models systems through event-driven processes, capturing state changes at specific points in time to analyze complex behaviors and resource flows. Digital twin simulation integrates DES with real-time data and IoT connectivity, enabling a dynamic, virtual representation of physical assets for predictive maintenance and operational optimization. Explore how these event-driven modeling approaches enhance decision-making and system performance in various industries.

Real-time data integration

Discrete Event Simulation (DES) models system behavior by representing the occurrence of discrete events over time without continuous feedback from real-world conditions. Digital Twin Simulation continuously integrates real-time data inputs from sensors and IoT devices to reflect the current state of the physical asset or process accurately. Explore how real-time data integration in digital twins revolutionizes predictive analytics and operational efficiency.

System representation fidelity

Discrete Event Simulation models systems by representing state changes at specific event points, providing simplified fidelity ideal for analyzing queue dynamics and process workflows. Digital Twin Simulation offers high-fidelity system representation by integrating real-time data and physics-based models, enabling accurate replication of complex behaviors and operational conditions. Explore more to understand which simulation method best suits your fidelity and analysis needs.

Source and External Links

Discrete Event Simulation - Autodesk - Discrete Event Simulation (DES) is a method that breaks workflows into distinct events to optimize and analyze systems, with steps including goal setting, model creation, data collection, validation, running experiments, and analysis to improve processes such as manufacturing.

Discrete Event Simulation (DES) - EBSCO Research Starters - DES is a computational technique that models complex systems by simulating sequential events to study system behaviors, enabling experimentation with scenarios for optimization and training in various fields.

Discrete-event simulation - Wikipedia - DES models a system as a sequence of distinct events occurring at specific times, allowing the simulation clock to jump between events, making it more efficient than continuous simulations by focusing on state changes only when events occur.

dowidth.com

dowidth.com