Circular supply chains emphasize resource efficiency by reusing, recycling, and refurbishing products to minimize waste and environmental impact, contrasting with traditional supply chains that follow a linear model of production, consumption, and disposal. Companies adopting circular supply chains can reduce costs, enhance sustainability, and meet growing consumer demand for eco-friendly practices. Explore how transitioning to a circular supply chain drives innovation and long-term competitive advantage.

Why it is important

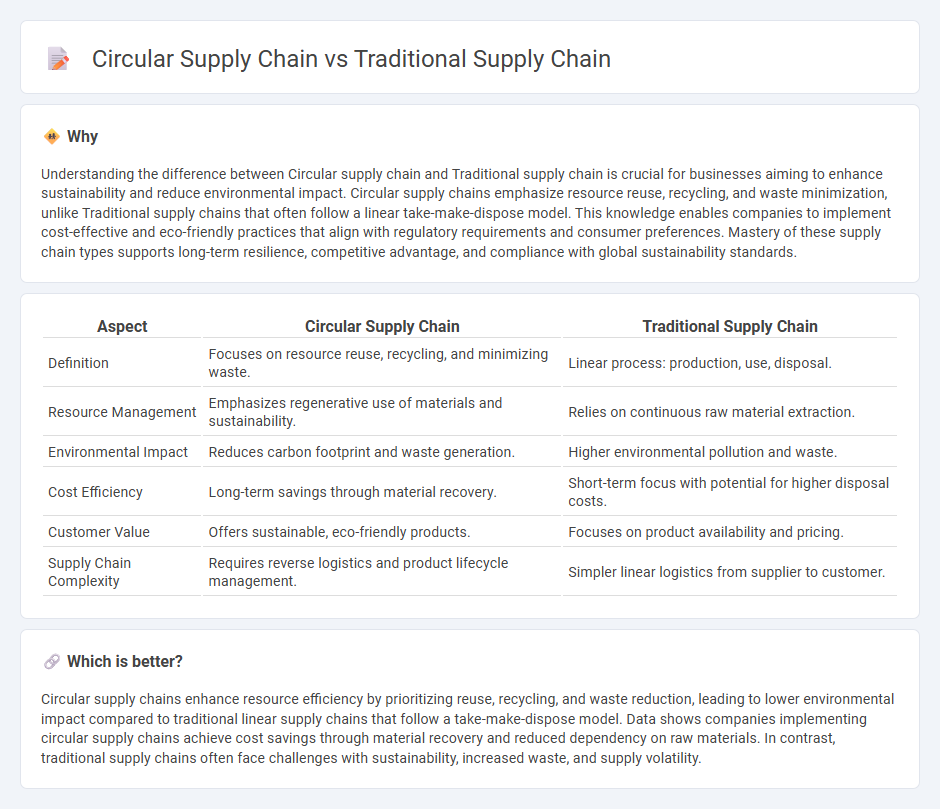

Understanding the difference between Circular supply chain and Traditional supply chain is crucial for businesses aiming to enhance sustainability and reduce environmental impact. Circular supply chains emphasize resource reuse, recycling, and waste minimization, unlike Traditional supply chains that often follow a linear take-make-dispose model. This knowledge enables companies to implement cost-effective and eco-friendly practices that align with regulatory requirements and consumer preferences. Mastery of these supply chain types supports long-term resilience, competitive advantage, and compliance with global sustainability standards.

Comparison Table

| Aspect | Circular Supply Chain | Traditional Supply Chain |

|---|---|---|

| Definition | Focuses on resource reuse, recycling, and minimizing waste. | Linear process: production, use, disposal. |

| Resource Management | Emphasizes regenerative use of materials and sustainability. | Relies on continuous raw material extraction. |

| Environmental Impact | Reduces carbon footprint and waste generation. | Higher environmental pollution and waste. |

| Cost Efficiency | Long-term savings through material recovery. | Short-term focus with potential for higher disposal costs. |

| Customer Value | Offers sustainable, eco-friendly products. | Focuses on product availability and pricing. |

| Supply Chain Complexity | Requires reverse logistics and product lifecycle management. | Simpler linear logistics from supplier to customer. |

Which is better?

Circular supply chains enhance resource efficiency by prioritizing reuse, recycling, and waste reduction, leading to lower environmental impact compared to traditional linear supply chains that follow a take-make-dispose model. Data shows companies implementing circular supply chains achieve cost savings through material recovery and reduced dependency on raw materials. In contrast, traditional supply chains often face challenges with sustainability, increased waste, and supply volatility.

Connection

Circular supply chains and traditional supply chains are connected through the integration of resource recovery and waste reduction practices into existing procurement, production, and distribution processes. Traditional supply chains focus on linear resource flow, while circular supply chains enhance sustainability by implementing recycling, remanufacturing, and refurbishing loops that feed materials back into the system. This connection enables businesses to optimize inventory management, reduce environmental impact, and improve supply chain resilience.

Key Terms

Linear Flow vs. Closed Loop

Traditional supply chains follow a linear flow where materials move from production to consumption and end in waste, emphasizing resource extraction and disposal. Circular supply chains implement a closed-loop system prioritizing resource recovery, reuse, and recycling to minimize waste and environmental impact. Explore deeper insights into how closed-loop strategies drive sustainable business models.

Waste Generation vs. Resource Recovery

Traditional supply chains generate significant waste by prioritizing linear processes of production, consumption, and disposal, leading to resource depletion and environmental pollution. Circular supply chains emphasize resource recovery by designing products for reuse, recycling, and remanufacturing, thus minimizing waste generation and enhancing sustainability. Explore how shifting from waste generation to resource recovery can transform industries and promote a resilient economy.

End-of-Life Disposal vs. Product Lifecycle Extension

Traditional supply chains often focus on end-of-life disposal, leading to waste accumulation and resource depletion. Circular supply chains prioritize product lifecycle extension by designing for reuse, repair, and recycling, reducing environmental impact and enhancing resource efficiency. Explore how shifting to circular supply models can drive sustainability and economic benefits.

Source and External Links

Traditional Supply Chain Management | Diggipacks - dyjybks - Traditional supply chain management involves designing, planning, implementing, and controlling supply chain activities to achieve net value and competitive infrastructure, focusing mainly on coordinating supply and demand with manual problem-solving and global logistics services usage.

Traditional Supply Chain vs. Digital Supply Chain - ZenGRC - Traditional supply chains are reactive systems based on historical rules, characterized by siloed standalone systems, manual processes, limited real-time data, and lack of agility and visibility, which delays problem resolution and reduces efficiency.

Key Differences Between Traditional and Modern Supply Chains - Traditional supply chains follow a linear, sequential flow of goods and information, marked by siloed operations, minimal collaboration, limited visibility, manual documentation, and a reactive approach to demand, leading to challenges in today's complex global market.

dowidth.com

dowidth.com