Dropshop and Vendor Managed Inventory (VMI) represent two distinct retail inventory management models that impact supply chain efficiency and cost control. Dropshop allows retailers to sell products without holding inventory, as suppliers ship directly to customers, reducing storage costs and risks. Explore the differences between Dropshop and VMI to optimize your retail strategy and enhance inventory management.

Why it is important

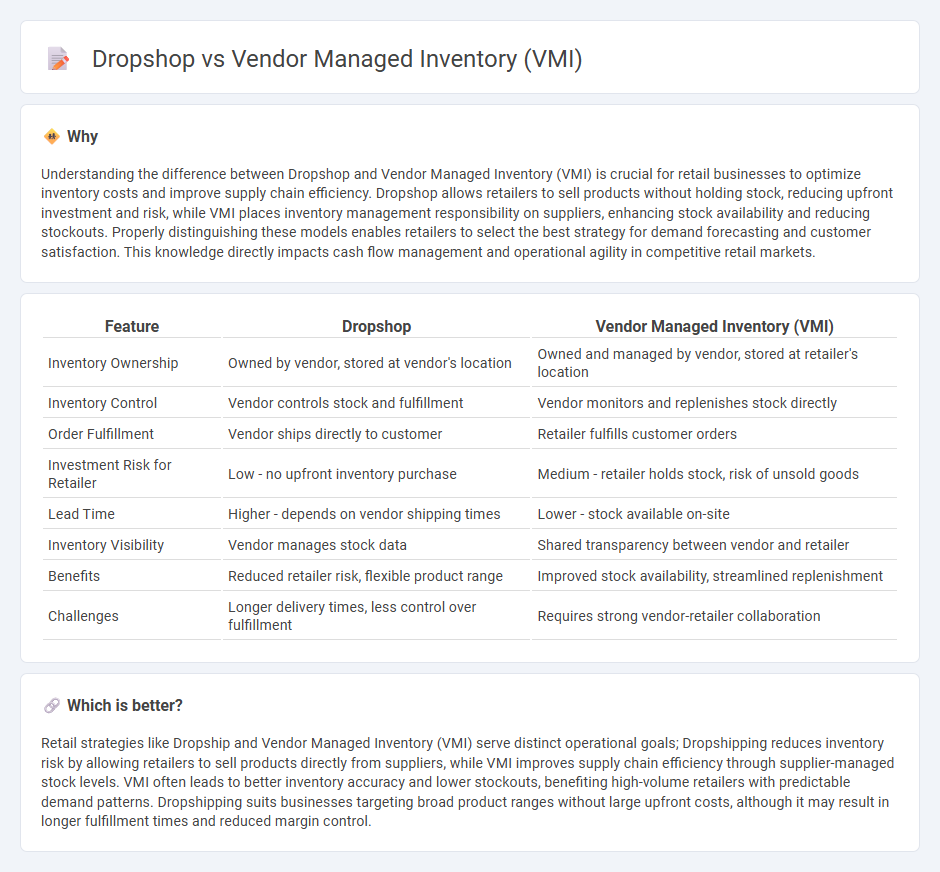

Understanding the difference between Dropshop and Vendor Managed Inventory (VMI) is crucial for retail businesses to optimize inventory costs and improve supply chain efficiency. Dropshop allows retailers to sell products without holding stock, reducing upfront investment and risk, while VMI places inventory management responsibility on suppliers, enhancing stock availability and reducing stockouts. Properly distinguishing these models enables retailers to select the best strategy for demand forecasting and customer satisfaction. This knowledge directly impacts cash flow management and operational agility in competitive retail markets.

Comparison Table

| Feature | Dropshop | Vendor Managed Inventory (VMI) |

|---|---|---|

| Inventory Ownership | Owned by vendor, stored at vendor's location | Owned and managed by vendor, stored at retailer's location |

| Inventory Control | Vendor controls stock and fulfillment | Vendor monitors and replenishes stock directly |

| Order Fulfillment | Vendor ships directly to customer | Retailer fulfills customer orders |

| Investment Risk for Retailer | Low - no upfront inventory purchase | Medium - retailer holds stock, risk of unsold goods |

| Lead Time | Higher - depends on vendor shipping times | Lower - stock available on-site |

| Inventory Visibility | Vendor manages stock data | Shared transparency between vendor and retailer |

| Benefits | Reduced retailer risk, flexible product range | Improved stock availability, streamlined replenishment |

| Challenges | Longer delivery times, less control over fulfillment | Requires strong vendor-retailer collaboration |

Which is better?

Retail strategies like Dropship and Vendor Managed Inventory (VMI) serve distinct operational goals; Dropshipping reduces inventory risk by allowing retailers to sell products directly from suppliers, while VMI improves supply chain efficiency through supplier-managed stock levels. VMI often leads to better inventory accuracy and lower stockouts, benefiting high-volume retailers with predictable demand patterns. Dropshipping suits businesses targeting broad product ranges without large upfront costs, although it may result in longer fulfillment times and reduced margin control.

Connection

Dropshop and Vendor Managed Inventory (VMI) streamline retail supply chains by enabling vendors to directly manage stock levels at retail locations, reducing stockouts and overstock situations. VMI systems provide real-time inventory data to vendors, allowing Dropshop platforms to automate order replenishment based on accurate demand forecasts. This integration enhances inventory accuracy, lowers carrying costs, and improves customer satisfaction across retail channels.

Key Terms

Inventory Ownership

Vendor Managed Inventory (VMI) shifts inventory ownership to the supplier, enabling them to monitor stock levels and replenish as needed, which reduces the buyer's risk and carrying costs. Dropshop maintains inventory ownership with the retailer or dropshipper, who relies on a third party to fulfill orders directly to customers without holding stock. Explore how each model impacts supply chain efficiency and cost structures for your business needs.

Order Fulfillment

Vendor Managed Inventory (VMI) optimizes order fulfillment by allowing suppliers to manage stock levels directly at the retailer's location, reducing stockouts and excess inventory through real-time data sharing. Dropshop streamlines order fulfillment by enabling direct shipping from the supplier to the customer, minimizing handling times and reducing logistical costs. Explore how these strategies impact supply chain efficiency and improve customer satisfaction.

Stock Replenishment

Vendor Managed Inventory (VMI) optimizes stock replenishment by allowing suppliers to monitor inventory levels and automatically restock based on real-time data, reducing stockouts and excess inventory. Dropshop relies on direct order fulfillment without prior inventory holding, which minimizes warehouse costs but can lead to longer delivery times and potential stock discrepancies. Explore the advantages and challenges of each approach to determine the best stock replenishment strategy for your business.

Source and External Links

What is vendor-managed inventory (VMI)? | Definition from TechTarget - Vendor-managed inventory (VMI) is an inventory management approach where the supplier manages and maintains inventory at the retailer's location, taking responsibility for replenishment and minimizing stockouts or overstock situations using real-time inventory data.

Vendor-managed inventory - Wikipedia - VMI is a practice in which the supplier optimizes the inventory held by a distributor, making ordering decisions based on shared inventory and sales data, unlike traditional models where the retailer controls ordering.

What Is Vendor-Managed Inventory (VMI)? - NetSuite - VMI is a supply chain strategy where suppliers use real-time sales and stock data to control replenishment orders, improving stock availability and efficiency for both suppliers and customers.

dowidth.com

dowidth.com