Retail shrinkage analytics leverages advanced data monitoring to identify and reduce losses caused by theft, errors, and fraud within inventory management. Supply chain visibility provides real-time tracking and insights into the flow of goods from suppliers to store shelves, enhancing operational efficiency and reducing disruptions. Explore how integrating retail shrinkage analytics with supply chain visibility can strengthen loss prevention and optimize inventory control.

Why it is important

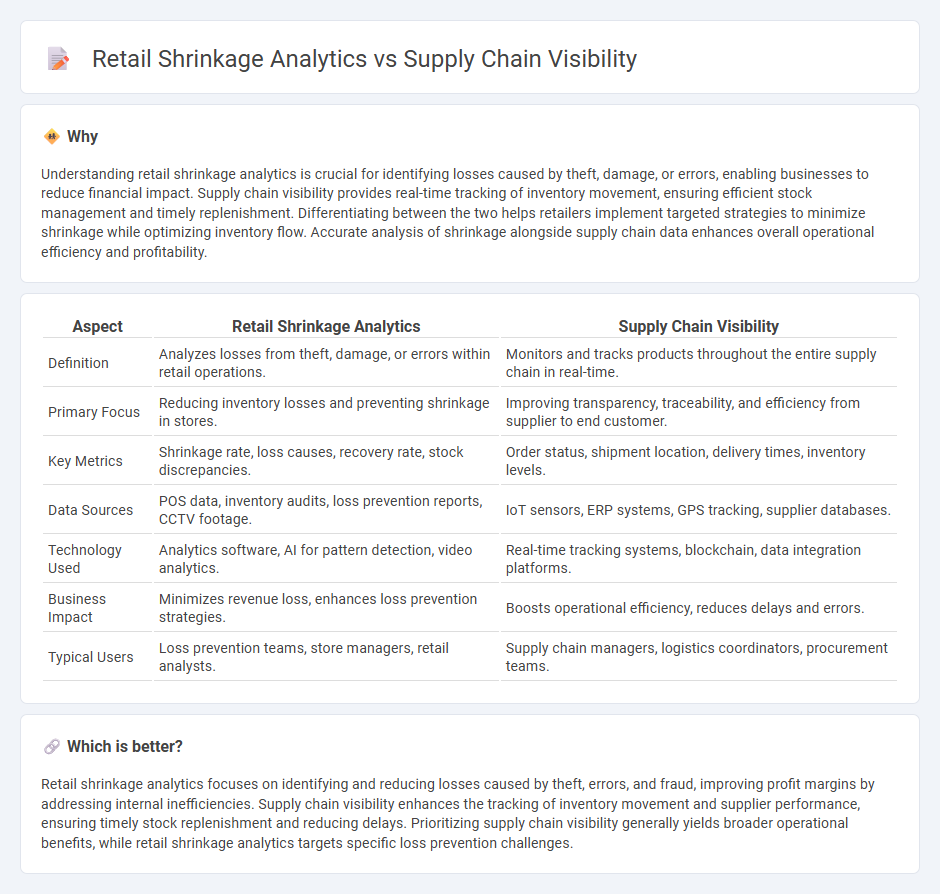

Understanding retail shrinkage analytics is crucial for identifying losses caused by theft, damage, or errors, enabling businesses to reduce financial impact. Supply chain visibility provides real-time tracking of inventory movement, ensuring efficient stock management and timely replenishment. Differentiating between the two helps retailers implement targeted strategies to minimize shrinkage while optimizing inventory flow. Accurate analysis of shrinkage alongside supply chain data enhances overall operational efficiency and profitability.

Comparison Table

| Aspect | Retail Shrinkage Analytics | Supply Chain Visibility |

|---|---|---|

| Definition | Analyzes losses from theft, damage, or errors within retail operations. | Monitors and tracks products throughout the entire supply chain in real-time. |

| Primary Focus | Reducing inventory losses and preventing shrinkage in stores. | Improving transparency, traceability, and efficiency from supplier to end customer. |

| Key Metrics | Shrinkage rate, loss causes, recovery rate, stock discrepancies. | Order status, shipment location, delivery times, inventory levels. |

| Data Sources | POS data, inventory audits, loss prevention reports, CCTV footage. | IoT sensors, ERP systems, GPS tracking, supplier databases. |

| Technology Used | Analytics software, AI for pattern detection, video analytics. | Real-time tracking systems, blockchain, data integration platforms. |

| Business Impact | Minimizes revenue loss, enhances loss prevention strategies. | Boosts operational efficiency, reduces delays and errors. |

| Typical Users | Loss prevention teams, store managers, retail analysts. | Supply chain managers, logistics coordinators, procurement teams. |

Which is better?

Retail shrinkage analytics focuses on identifying and reducing losses caused by theft, errors, and fraud, improving profit margins by addressing internal inefficiencies. Supply chain visibility enhances the tracking of inventory movement and supplier performance, ensuring timely stock replenishment and reducing delays. Prioritizing supply chain visibility generally yields broader operational benefits, while retail shrinkage analytics targets specific loss prevention challenges.

Connection

Retail shrinkage analytics leverages data on inventory discrepancies to identify and quantify losses caused by theft, errors, or damage, providing actionable insights for loss prevention strategies. Enhanced supply chain visibility enables real-time tracking of products from suppliers to shelves, improving inventory accuracy and reducing opportunities for shrinkage. Integrating shrinkage analytics with supply chain visibility empowers retailers to optimize stock management, minimize losses, and increase overall operational efficiency.

Key Terms

**Supply Chain Visibility:**

Supply chain visibility enhances real-time tracking of inventory, shipment status, and demand fluctuations, enabling proactive decision-making and reducing delays. Advanced technologies like IoT sensors and AI-driven analytics improve transparency across all supply chain stages, minimizing stockouts and overstock situations. Explore how optimizing supply chain visibility can transform operational efficiency and profitability.

Real-time Tracking

Real-time tracking in supply chain visibility enables continuous monitoring of inventory movement, reducing delays and improving accuracy in demand forecasting. Retail shrinkage analytics leverage real-time data to identify theft, spoilage, and administrative errors, minimizing losses and enhancing store profitability. Explore more insights on integrating these technologies for optimized retail operations and loss prevention.

Data Integration

Supply chain visibility emphasizes real-time data integration across procurement, logistics, and inventory systems to enhance transparency and operational efficiency. Retail shrinkage analytics relies on integrating point-of-sale, loss prevention, and inventory data to identify patterns of theft, errors, and fraud. Explore how seamless data integration drives both supply chain optimization and shrinkage reduction strategies.

Source and External Links

What is Supply Chain Visibility? Meaning and Definition - GEP - Supply chain visibility is the ability to track inventory and shipments in real-time throughout the supply chain, enabling data-driven decisions to optimize inventory, improve coordination, reduce costs, and build resilient supply chains via AI-driven platforms.

What is Supply Chain Visibility? - Tibco - Supply chain visibility tracks a product from raw materials to customers, providing a transparent, unified view across all supply chain steps to reduce errors and improve customer satisfaction and efficiency.

What Is Supply Chain Visibility (SCV)? Definition & Examples - Supply chain visibility offers transparency by tracking components and products from suppliers through manufacturing to customers, enhancing communication, enabling quick issue resolution, and maintaining accurate inventories and shipment status.

dowidth.com

dowidth.com