Phantom inventory occurs when a retail system shows stock available that physically isn't present, leading to discrepancies in order fulfillment and inventory management. Stockout represents the complete depletion of a product, causing missed sales opportunities and dissatisfied customers. Explore how understanding phantom inventory and stockout impacts retail efficiency and customer satisfaction.

Why it is important

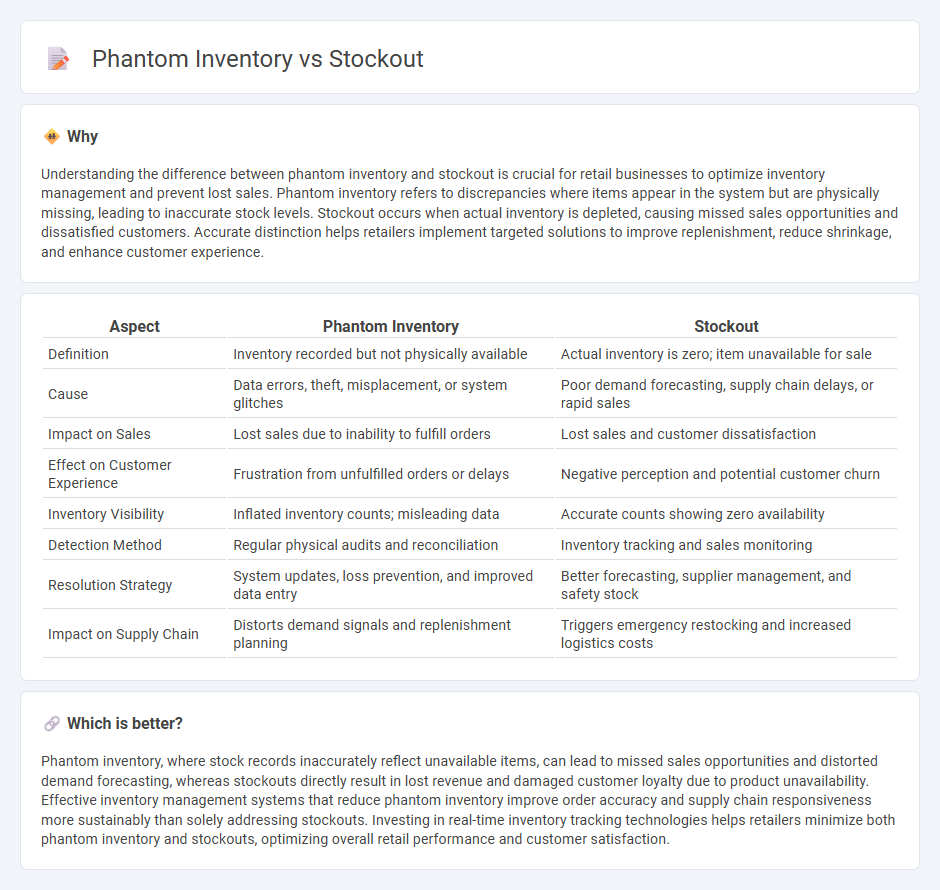

Understanding the difference between phantom inventory and stockout is crucial for retail businesses to optimize inventory management and prevent lost sales. Phantom inventory refers to discrepancies where items appear in the system but are physically missing, leading to inaccurate stock levels. Stockout occurs when actual inventory is depleted, causing missed sales opportunities and dissatisfied customers. Accurate distinction helps retailers implement targeted solutions to improve replenishment, reduce shrinkage, and enhance customer experience.

Comparison Table

| Aspect | Phantom Inventory | Stockout |

|---|---|---|

| Definition | Inventory recorded but not physically available | Actual inventory is zero; item unavailable for sale |

| Cause | Data errors, theft, misplacement, or system glitches | Poor demand forecasting, supply chain delays, or rapid sales |

| Impact on Sales | Lost sales due to inability to fulfill orders | Lost sales and customer dissatisfaction |

| Effect on Customer Experience | Frustration from unfulfilled orders or delays | Negative perception and potential customer churn |

| Inventory Visibility | Inflated inventory counts; misleading data | Accurate counts showing zero availability |

| Detection Method | Regular physical audits and reconciliation | Inventory tracking and sales monitoring |

| Resolution Strategy | System updates, loss prevention, and improved data entry | Better forecasting, supplier management, and safety stock |

| Impact on Supply Chain | Distorts demand signals and replenishment planning | Triggers emergency restocking and increased logistics costs |

Which is better?

Phantom inventory, where stock records inaccurately reflect unavailable items, can lead to missed sales opportunities and distorted demand forecasting, whereas stockouts directly result in lost revenue and damaged customer loyalty due to product unavailability. Effective inventory management systems that reduce phantom inventory improve order accuracy and supply chain responsiveness more sustainably than solely addressing stockouts. Investing in real-time inventory tracking technologies helps retailers minimize both phantom inventory and stockouts, optimizing overall retail performance and customer satisfaction.

Connection

Phantom inventory occurs when a retail system shows stock on hand that is not physically available, leading to inaccurate inventory counts. This discrepancy directly contributes to stockouts, where customer demand cannot be met despite system records indicating sufficient inventory levels. Effective inventory management systems and regular audits are essential to minimize phantom inventory and prevent costly stockouts in retail operations.

Key Terms

Inventory Accuracy

Stockout occurs when physical inventory is depleted despite customer demand, causing missed sales, while phantom inventory arises when recorded stock exists in the system but is unavailable physically, leading to inaccurate inventory data. Inventory accuracy is crucial to minimizing both issues, which disrupt supply chains and inflate operational costs by triggering unnecessary replenishments or lost revenue due to unfulfilled orders. Explore effective strategies for improving inventory accuracy and overcoming the challenges of stockouts and phantom inventory.

Replenishment

Stockout occurs when actual inventory is completely depleted, leading to lost sales and unmet customer demand, while phantom inventory refers to inaccurate stock data that falsely indicates availability due to errors in tracking or reporting. Effective replenishment strategies depend on accurate inventory visibility to prevent stockouts by timely restocking and to correct phantom inventory through regular audits and system updates. Explore advanced replenishment techniques to optimize inventory accuracy and maintain seamless product availability.

Point-of-Sale (POS)

Stockout occurs when the Point-of-Sale (POS) system shows zero available stock, leading to missed sales and dissatisfied customers, while phantom inventory results from discrepancies where the POS displays inventory incorrectly, causing overstocking or misguided replenishment. Effective POS inventory management requires accurate data synchronization between physical stock and digital records to prevent revenue loss and improve supply chain efficiency. Explore advanced POS solutions to optimize inventory accuracy and boost retail performance.

Source and External Links

Stockout: Meaning, Calculation, Impact and Examples - A stockout occurs when a company runs out of a particular good, causing lost sales and dissatisfied customers, and is often due to supply not meeting demand or inventory control failures; managing inventory and demand forecasting can help avoid this issue.

What are Stockouts and How to Prevent Them? - Stockouts happen when inventory for a demanded item is zero with outstanding orders, disrupting supply chains and manufacturing, distinguished from out-of-stock or backorder situations, with prevention relying on effective inventory management.

Stockout - A stockout or out-of-stock event occurs when inventory is depleted, widely seen in retail sectors, often caused by poor shelf replenishment rather than upstream supply issues, resulting in lost sales and customer dissatisfaction.

dowidth.com

dowidth.com