Micro fulfillment centers utilize compact automation and robotics within urban areas to rapidly process and deliver online orders, enhancing last-mile delivery efficiency. Pop-up fulfillment centers are temporary, flexible spaces set up during peak demand periods or events to scale fulfillment capacity and reduce delivery times. Explore how these innovative retail solutions can transform your supply chain strategy.

Why it is important

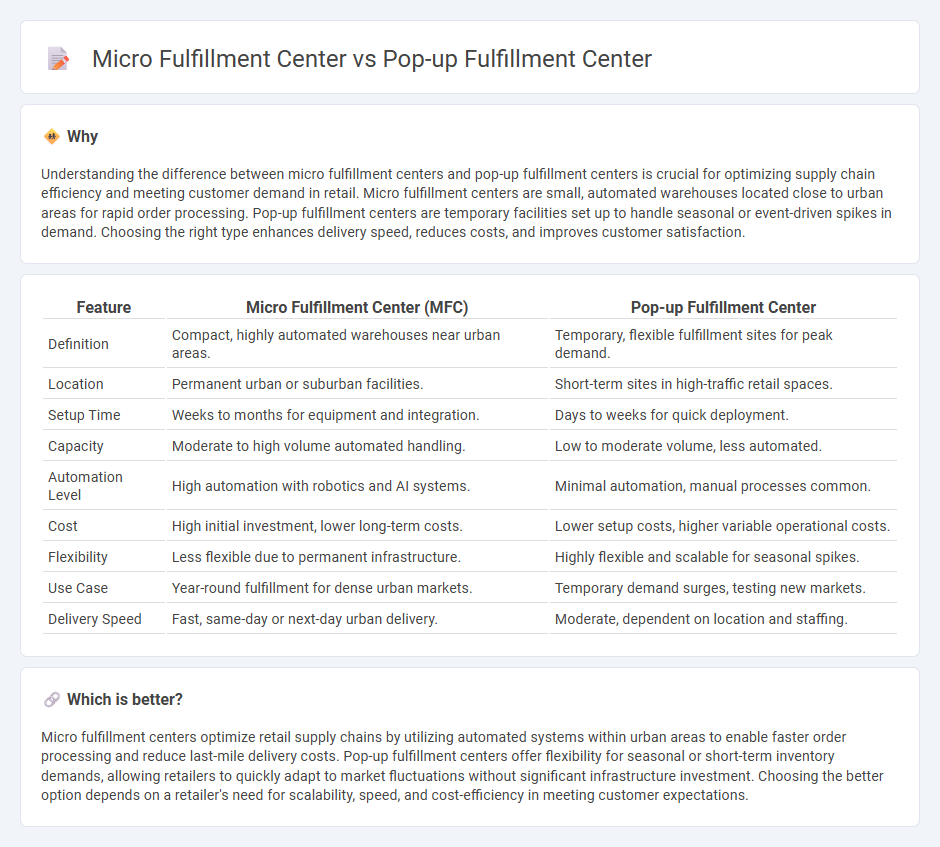

Understanding the difference between micro fulfillment centers and pop-up fulfillment centers is crucial for optimizing supply chain efficiency and meeting customer demand in retail. Micro fulfillment centers are small, automated warehouses located close to urban areas for rapid order processing. Pop-up fulfillment centers are temporary facilities set up to handle seasonal or event-driven spikes in demand. Choosing the right type enhances delivery speed, reduces costs, and improves customer satisfaction.

Comparison Table

| Feature | Micro Fulfillment Center (MFC) | Pop-up Fulfillment Center |

|---|---|---|

| Definition | Compact, highly automated warehouses near urban areas. | Temporary, flexible fulfillment sites for peak demand. |

| Location | Permanent urban or suburban facilities. | Short-term sites in high-traffic retail spaces. |

| Setup Time | Weeks to months for equipment and integration. | Days to weeks for quick deployment. |

| Capacity | Moderate to high volume automated handling. | Low to moderate volume, less automated. |

| Automation Level | High automation with robotics and AI systems. | Minimal automation, manual processes common. |

| Cost | High initial investment, lower long-term costs. | Lower setup costs, higher variable operational costs. |

| Flexibility | Less flexible due to permanent infrastructure. | Highly flexible and scalable for seasonal spikes. |

| Use Case | Year-round fulfillment for dense urban markets. | Temporary demand surges, testing new markets. |

| Delivery Speed | Fast, same-day or next-day urban delivery. | Moderate, dependent on location and staffing. |

Which is better?

Micro fulfillment centers optimize retail supply chains by utilizing automated systems within urban areas to enable faster order processing and reduce last-mile delivery costs. Pop-up fulfillment centers offer flexibility for seasonal or short-term inventory demands, allowing retailers to quickly adapt to market fluctuations without significant infrastructure investment. Choosing the better option depends on a retailer's need for scalability, speed, and cost-efficiency in meeting customer expectations.

Connection

Micro fulfillment centers (MFCs) and pop-up fulfillment centers both aim to enhance retail supply chain efficiency by enabling faster order processing closer to customers. MFCs are small-scale automated warehouses typically located within urban areas or retail stores, while pop-up fulfillment centers are temporary facilities set up to manage demand spikes or serve specific geographic regions. Their connection lies in their shared goal of optimizing last-mile delivery and improving inventory responsiveness in the retail sector.

Key Terms

Temporary deployment

Pop-up fulfillment centers provide rapid, short-term storage and order processing solutions in response to seasonal spikes or promotional campaigns, enabling retailers to scale operations quickly without long-term commitments. Micro fulfillment centers are strategically placed, smaller warehouses designed for ongoing, high-speed order fulfillment near urban areas, improving delivery times and reducing last-mile costs. Explore the differences and benefits of temporary deployment strategies for both fulfillment models to optimize your supply chain efficiency.

Urban proximity

Pop-up fulfillment centers leverage temporary, flexible spaces within urban environments to quickly meet fluctuating demand and reduce last-mile delivery times. Micro fulfillment centers, often automated and compact, are strategically placed in dense urban areas to optimize inventory management and accelerate order processing close to consumers. Explore the benefits and applications of both solutions to enhance urban supply chain efficiency.

Automated picking

Pop-up fulfillment centers provide temporary storage solutions close to high-demand areas, enabling rapid order processing and delivery during peak seasons using basic automated picking technologies. Micro fulfillment centers use advanced robotic systems and AI-driven automated picking processes to optimize inventory management and increase picking accuracy within small, permanent urban spaces. Explore how automated picking innovations differentiate these fulfillment models to enhance efficiency and cost-effectiveness.

Source and External Links

Pop-Up Distribution Centers Overcome Last-Mile Delivery Obstacles - Pop-up fulfillment centers, or micro-fulfillment centers, are temporary distribution points set up close to customers to speed delivery and manage demand surges cost-effectively, especially useful during COVID-19 to shorten supply chains and improve delivery times.

Pop-up Distribution Centers - Pop-up fulfillment centers provide flexible, temporary localized operations ranging in size and duration, enabling retailers to decentralize inventory and meet fast delivery demands while maintaining customer experience quality.

Pop-Up Warehousing: Definition, Risks, and Benefits - Pop-up fulfillment centers make use of underutilized spaces temporarily to add scalable, on-demand e-commerce micro-fulfillment capacity during peak seasons or changing market needs, reducing overhead and optimizing supply chain flexibility.

dowidth.com

dowidth.com