Retail shrinkage analytics focuses on identifying and reducing losses caused by theft, errors, and fraud to improve profitability. Inventory optimization uses data-driven techniques to balance stock levels, minimize carrying costs, and meet customer demand efficiently. Explore how integrating shrinkage analytics with inventory optimization can significantly enhance retail operations.

Why it is important

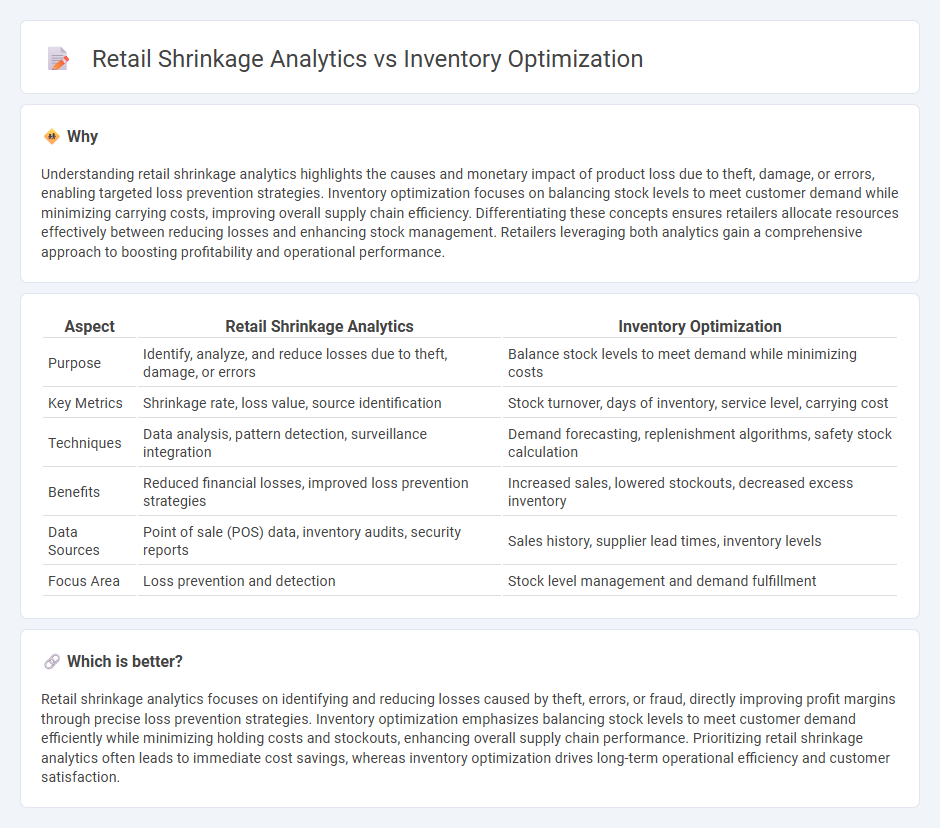

Understanding retail shrinkage analytics highlights the causes and monetary impact of product loss due to theft, damage, or errors, enabling targeted loss prevention strategies. Inventory optimization focuses on balancing stock levels to meet customer demand while minimizing carrying costs, improving overall supply chain efficiency. Differentiating these concepts ensures retailers allocate resources effectively between reducing losses and enhancing stock management. Retailers leveraging both analytics gain a comprehensive approach to boosting profitability and operational performance.

Comparison Table

| Aspect | Retail Shrinkage Analytics | Inventory Optimization |

|---|---|---|

| Purpose | Identify, analyze, and reduce losses due to theft, damage, or errors | Balance stock levels to meet demand while minimizing costs |

| Key Metrics | Shrinkage rate, loss value, source identification | Stock turnover, days of inventory, service level, carrying cost |

| Techniques | Data analysis, pattern detection, surveillance integration | Demand forecasting, replenishment algorithms, safety stock calculation |

| Benefits | Reduced financial losses, improved loss prevention strategies | Increased sales, lowered stockouts, decreased excess inventory |

| Data Sources | Point of sale (POS) data, inventory audits, security reports | Sales history, supplier lead times, inventory levels |

| Focus Area | Loss prevention and detection | Stock level management and demand fulfillment |

Which is better?

Retail shrinkage analytics focuses on identifying and reducing losses caused by theft, errors, or fraud, directly improving profit margins through precise loss prevention strategies. Inventory optimization emphasizes balancing stock levels to meet customer demand efficiently while minimizing holding costs and stockouts, enhancing overall supply chain performance. Prioritizing retail shrinkage analytics often leads to immediate cost savings, whereas inventory optimization drives long-term operational efficiency and customer satisfaction.

Connection

Retail shrinkage analytics identifies patterns and causes of inventory loss, enabling retailers to implement targeted strategies that reduce theft, damage, and administrative errors. Inventory optimization uses these insights to maintain accurate stock levels, improving replenishment efficiency and minimizing overstock or stockouts. Together, these approaches enhance profitability by reducing shrinkage-related costs and ensuring product availability.

Key Terms

**Inventory Optimization:**

Inventory optimization maximizes stock efficiency by analyzing demand forecasts, lead times, and carrying costs to reduce excess inventory and stockouts. It leverages advanced algorithms and real-time data integration for precise replenishment and improved cash flow management. Explore how inventory optimization techniques can drive profitability and operational excellence.

Demand Forecasting

Inventory optimization leverages demand forecasting to balance stock levels, minimizing overstock and understock risks. Retail shrinkage analytics focuses on identifying and reducing losses due to theft, damage, or errors, which indirectly impacts accurate demand planning. Explore detailed strategies to enhance demand forecasting accuracy and improve retail inventory management.

Replenishment Planning

Inventory optimization and retail shrinkage analytics both play critical roles in replenishment planning by enhancing stock accuracy and reducing losses. Inventory optimization focuses on maintaining the right stock levels to meet demand without overstocking, while retail shrinkage analytics identifies and mitigates losses from theft, damage, or administrative errors. Explore how integrating these strategies can improve replenishment efficiency and boost retail profitability.

Source and External Links

What Is Inventory Optimization? Benefits and Techniques - NetSuite - Inventory optimization is the process of balancing stock with demand to minimize costs while ensuring product availability, using techniques like demand forecasting and inventory turnover ratio to manage supply and reduce risks such as overstocking or stockouts.

What Is Inventory Optimization? | IBM - Inventory optimization uses data, analytics, and advanced algorithms to maintain the right inventory levels for each SKU by predicting demand, setting reorder points, managing safety stock, and applying strategies like ABC analysis to prioritize items.

Inventory Optimization Guide - ShipBob - Techniques for inventory optimization include demand forecasting using historical sales data and determining safety stock levels to buffer against supply chain disruptions or demand surges, supported by tools that track SKU performance for better planning.

dowidth.com

dowidth.com