Smart shelf technology integrates RFID sensors and real-time data analytics to monitor product availability and customer interactions directly on store shelves, enhancing inventory accuracy and shopper experience. Inventory management software focuses on tracking stock levels, orders, sales, and deliveries across multiple channels to optimize supply chain efficiency and reduce stockouts or overstocking. Discover how combining smart shelf technology with advanced inventory management software can revolutionize retail operations.

Why it is important

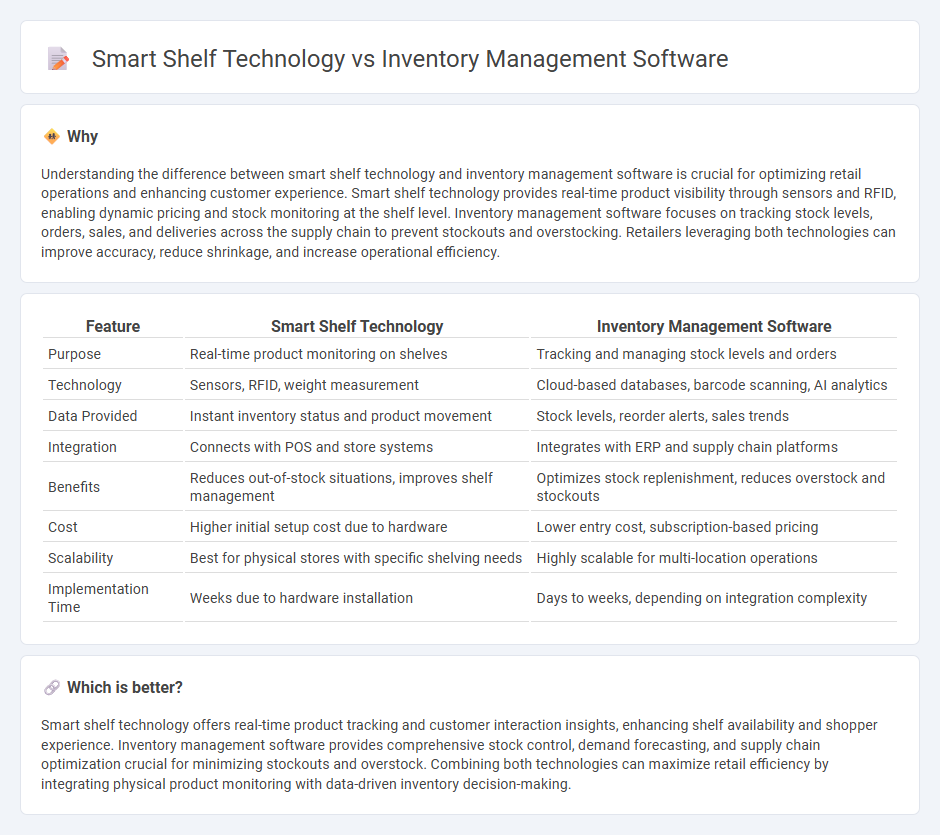

Understanding the difference between smart shelf technology and inventory management software is crucial for optimizing retail operations and enhancing customer experience. Smart shelf technology provides real-time product visibility through sensors and RFID, enabling dynamic pricing and stock monitoring at the shelf level. Inventory management software focuses on tracking stock levels, orders, sales, and deliveries across the supply chain to prevent stockouts and overstocking. Retailers leveraging both technologies can improve accuracy, reduce shrinkage, and increase operational efficiency.

Comparison Table

| Feature | Smart Shelf Technology | Inventory Management Software |

|---|---|---|

| Purpose | Real-time product monitoring on shelves | Tracking and managing stock levels and orders |

| Technology | Sensors, RFID, weight measurement | Cloud-based databases, barcode scanning, AI analytics |

| Data Provided | Instant inventory status and product movement | Stock levels, reorder alerts, sales trends |

| Integration | Connects with POS and store systems | Integrates with ERP and supply chain platforms |

| Benefits | Reduces out-of-stock situations, improves shelf management | Optimizes stock replenishment, reduces overstock and stockouts |

| Cost | Higher initial setup cost due to hardware | Lower entry cost, subscription-based pricing |

| Scalability | Best for physical stores with specific shelving needs | Highly scalable for multi-location operations |

| Implementation Time | Weeks due to hardware installation | Days to weeks, depending on integration complexity |

Which is better?

Smart shelf technology offers real-time product tracking and customer interaction insights, enhancing shelf availability and shopper experience. Inventory management software provides comprehensive stock control, demand forecasting, and supply chain optimization crucial for minimizing stockouts and overstock. Combining both technologies can maximize retail efficiency by integrating physical product monitoring with data-driven inventory decision-making.

Connection

Smart shelf technology integrates real-time data collection with inventory management software to optimize stock levels and reduce out-of-stock incidents. Sensors embedded in shelves track product movement and automatically update inventory databases, enabling accurate demand forecasting and faster replenishment. This seamless connectivity enhances retail operations by improving stock accuracy, minimizing shrinkage, and boosting overall efficiency.

Key Terms

Stock tracking

Inventory management software offers comprehensive stock tracking by automating data entry, real-time inventory updates, and detailed reporting, which helps businesses optimize reorder points and reduce stockouts. Smart shelf technology enhances stock tracking through embedded sensors and RFID tags that provide instant visibility of product levels on shelves, enabling accurate, real-time monitoring and minimizing human error. Explore the latest advancements in stock tracking solutions to discover which technology best fits your operational needs.

Real-time monitoring

Inventory management software provides real-time monitoring by tracking stock levels, sales data, and supply chain movements through cloud-based platforms, ensuring efficient inventory control and reducing stockouts. Smart shelf technology enhances real-time monitoring by using IoT sensors and RFID tags to detect product presence and movement instantly on the shelf, enabling automatic stock updates and alerting staff to restocking needs immediately. Explore how combining these technologies can revolutionize your inventory accuracy and operational efficiency.

Automated replenishment

Inventory management software leverages real-time data analytics and predictive algorithms to automate replenishment processes, reducing stockouts and overstock situations. Smart shelf technology integrates sensors and RFID to monitor product levels instantly, triggering automated restocking alerts or orders without human intervention. Explore how these technologies transform supply chain efficiency and optimize inventory control.

Source and External Links

Zoho Inventory - Free inventory management software for growing businesses - Zoho Inventory offers free software designed for small to growing businesses to manage inventory seamlessly across multiple channels, including features like sales tracking, purchase monitoring, warehouse control, item tracking with serial/batch numbers, and smart automation for reports.

inFlow Inventory Management Software - inFlow provides an easy-to-use inventory system tailored for small to mid-sized businesses, handling stock levels, sales, shipping, barcoding, and manufacturing, with scalable solutions and hardware support like scanners and label printers.

Sortly: Inventory Simplified - Sortly is an all-in-one inventory software suited for businesses of all sizes, offering barcode and QR code scanning, photo uploads, real-time syncing across devices, low-stock alerts, and advanced reporting to help efficiently track inventory anytime, anywhere.

dowidth.com

dowidth.com