Drop shipping automation streamlines retail operations by eliminating inventory storage, allowing direct product shipment from suppliers to customers and reducing overhead costs. In-store inventory management involves maintaining physical stock, enabling immediate product availability and enhancing customer experience with tactile shopping. Discover how each approach impacts retail efficiency and customer satisfaction to optimize your business strategy.

Why it is important

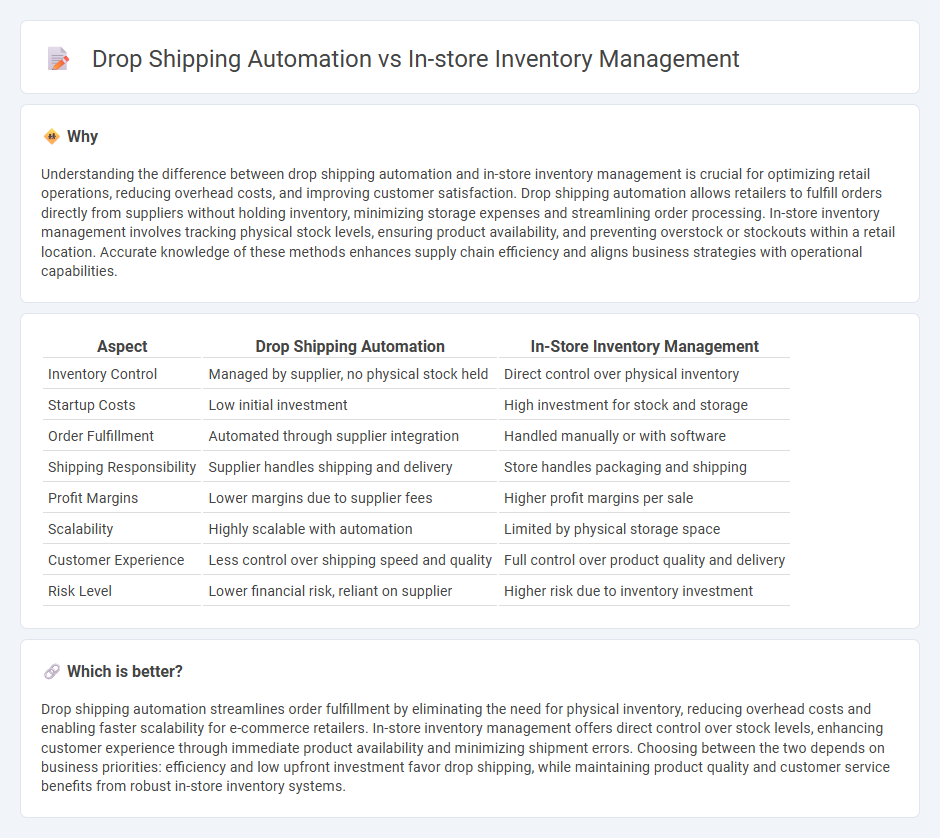

Understanding the difference between drop shipping automation and in-store inventory management is crucial for optimizing retail operations, reducing overhead costs, and improving customer satisfaction. Drop shipping automation allows retailers to fulfill orders directly from suppliers without holding inventory, minimizing storage expenses and streamlining order processing. In-store inventory management involves tracking physical stock levels, ensuring product availability, and preventing overstock or stockouts within a retail location. Accurate knowledge of these methods enhances supply chain efficiency and aligns business strategies with operational capabilities.

Comparison Table

| Aspect | Drop Shipping Automation | In-Store Inventory Management |

|---|---|---|

| Inventory Control | Managed by supplier, no physical stock held | Direct control over physical inventory |

| Startup Costs | Low initial investment | High investment for stock and storage |

| Order Fulfillment | Automated through supplier integration | Handled manually or with software |

| Shipping Responsibility | Supplier handles shipping and delivery | Store handles packaging and shipping |

| Profit Margins | Lower margins due to supplier fees | Higher profit margins per sale |

| Scalability | Highly scalable with automation | Limited by physical storage space |

| Customer Experience | Less control over shipping speed and quality | Full control over product quality and delivery |

| Risk Level | Lower financial risk, reliant on supplier | Higher risk due to inventory investment |

Which is better?

Drop shipping automation streamlines order fulfillment by eliminating the need for physical inventory, reducing overhead costs and enabling faster scalability for e-commerce retailers. In-store inventory management offers direct control over stock levels, enhancing customer experience through immediate product availability and minimizing shipment errors. Choosing between the two depends on business priorities: efficiency and low upfront investment favor drop shipping, while maintaining product quality and customer service benefits from robust in-store inventory systems.

Connection

Drop shipping automation enhances retail efficiency by synchronizing online orders with suppliers, reducing the need for physical stock and enabling seamless order fulfillment. In-store inventory management integrates real-time data to monitor stock levels, preventing overstocking and understocking. The connection lies in coordinated data exchange and predictive analytics that align supply chain responsiveness with accurate inventory availability.

Key Terms

**In-Store Inventory Management:**

In-store inventory management optimizes stock levels by using real-time tracking systems to reduce shrinkage and prevent overstocking, improving cash flow and customer satisfaction. Advanced barcode scanning and RFID technologies streamline auditing processes and enhance accuracy in replenishment decisions. Discover how integrating innovative in-store inventory management tools can transform your retail operations.

Stock Replenishment

In-store inventory management relies on real-time stock monitoring and automated reorder triggers to maintain optimal product levels, reducing stockouts and enhancing customer satisfaction. Drop shipping automation eliminates the need for physical stock by directly syncing supplier inventory with online orders, ensuring accurate availability without holding inventory. Explore the benefits and challenges of each approach to optimize your retail strategy.

Barcode Scanning

Barcode scanning enhances in-store inventory management by providing real-time stock tracking, reducing human errors, and streamlining restocking processes. Drop shipping automation relies less on barcode scanning since products are shipped directly from suppliers, focusing instead on order processing and supplier communication. Explore the advantages and challenges of both methods to optimize your supply chain efficiency.

Source and External Links

Retail Inventory Management: What It Is, Steps, Practices and Tips - In-store inventory management involves creating a centralized record of all products including details like SKU, brand, stock quantities, reorder points, and locations to ensure the right merchandise is in stock without overstocking or stockouts.

What Is Store Inventory Control and Why It Matters for Retail Success - Store inventory control tracks stock levels across physical retail stores, using techniques such as FIFO and LIFO to manage stock availability and prevent dead stock, enhanced by software tools for accuracy and automation.

Retail Inventory Management Fundamentals | Salesforce US - Effective in-store inventory management includes forecasting inventory needs, real-time stock tracking, automated replenishment, and balancing cost management with product availability through integrated retail inventory systems and AI-driven tools.

dowidth.com

dowidth.com