Microfulfillment centers optimize last-mile delivery by utilizing compact, automated storage solutions to quickly process online orders within urban areas. Cross-docking facilities streamline supply chains by transferring products directly from inbound to outbound transportation, minimizing storage time and reducing inventory costs. Explore the key differences and benefits of each to enhance your retail logistics strategy.

Why it is important

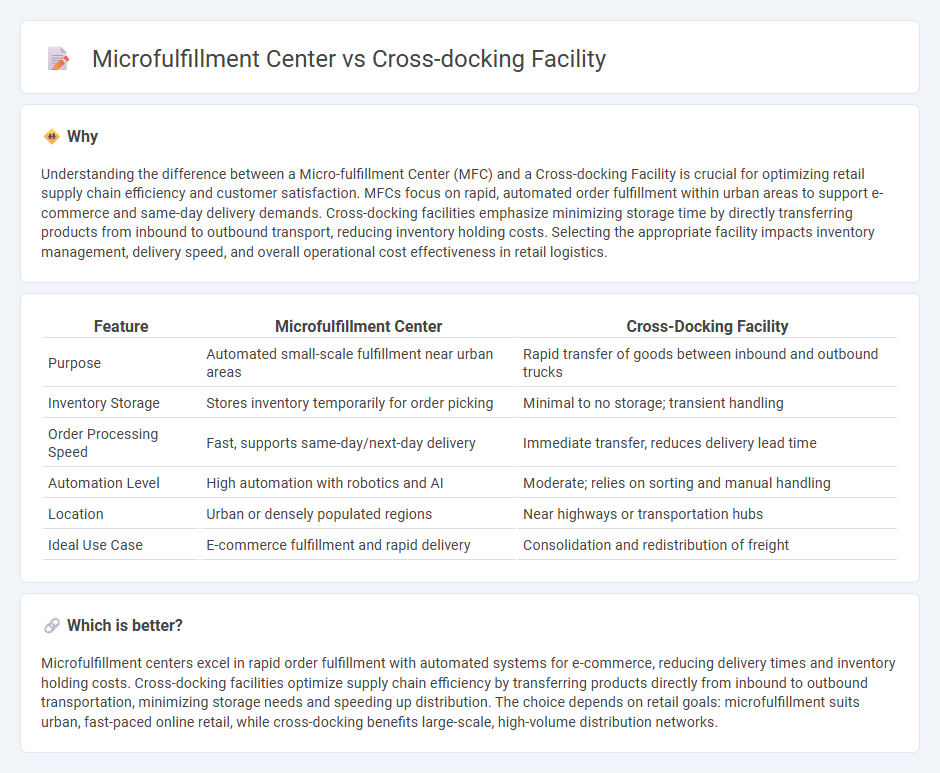

Understanding the difference between a Micro-fulfillment Center (MFC) and a Cross-docking Facility is crucial for optimizing retail supply chain efficiency and customer satisfaction. MFCs focus on rapid, automated order fulfillment within urban areas to support e-commerce and same-day delivery demands. Cross-docking facilities emphasize minimizing storage time by directly transferring products from inbound to outbound transport, reducing inventory holding costs. Selecting the appropriate facility impacts inventory management, delivery speed, and overall operational cost effectiveness in retail logistics.

Comparison Table

| Feature | Microfulfillment Center | Cross-Docking Facility |

|---|---|---|

| Purpose | Automated small-scale fulfillment near urban areas | Rapid transfer of goods between inbound and outbound trucks |

| Inventory Storage | Stores inventory temporarily for order picking | Minimal to no storage; transient handling |

| Order Processing Speed | Fast, supports same-day/next-day delivery | Immediate transfer, reduces delivery lead time |

| Automation Level | High automation with robotics and AI | Moderate; relies on sorting and manual handling |

| Location | Urban or densely populated regions | Near highways or transportation hubs |

| Ideal Use Case | E-commerce fulfillment and rapid delivery | Consolidation and redistribution of freight |

Which is better?

Microfulfillment centers excel in rapid order fulfillment with automated systems for e-commerce, reducing delivery times and inventory holding costs. Cross-docking facilities optimize supply chain efficiency by transferring products directly from inbound to outbound transportation, minimizing storage needs and speeding up distribution. The choice depends on retail goals: microfulfillment suits urban, fast-paced online retail, while cross-docking benefits large-scale, high-volume distribution networks.

Connection

Microfulfillment centers and cross-docking facilities both streamline retail supply chains by reducing inventory holding and accelerating order fulfillment. Microfulfillment centers focus on rapid picking and packing near urban areas, while cross-docking facilities transfer products directly from inbound to outbound transportation with minimal storage. Integrating these strategies enhances efficiency, cuts delivery times, and supports just-in-time inventory practices in retail operations.

Key Terms

Inventory Turnover

Cross-docking facilities significantly enhance inventory turnover by minimizing storage time and directly transferring goods from inbound to outbound transportation, enabling faster product movement and reduced holding costs. Microfulfillment centers, while also improving turnover rates, primarily optimize last-mile delivery with automated, small-scale storage systems strategically located near urban centers, supporting rapid order fulfillment of e-commerce and grocery items. Explore detailed comparisons and operational benefits to determine which solution best boosts inventory turnover for your supply chain.

Last-Mile Delivery

Cross-docking facilities streamline last-mile delivery by quickly transferring goods from inbound to outbound transportation without long-term storage, reducing handling time and costs. Microfulfillment centers, situated closer to urban consumers, enable rapid order processing and delivery by leveraging automation and smaller footprints. Discover how these last-mile delivery solutions transform supply chain efficiency and customer satisfaction.

Order Consolidation

Cross-docking facilities streamline order consolidation by directly transferring products from inbound to outbound transportation with minimal storage, significantly reducing handling time and inventory holding costs. Microfulfillment centers enhance order consolidation by using automated systems within urban warehouses to gather items efficiently, catering to faster delivery demands and smaller order sizes. Explore the differences in order consolidation strategies to optimize your supply chain efficiency.

Source and External Links

Understanding cross-docking: A comprehensive guide - Maersk - A cross-docking facility is designed to transfer goods quickly from inbound to outbound transportation with minimal or no storage, using layouts like U-, I-, or L-shaped warehouses, optimized dock doors, real-time systems, and trained staff to streamline operations efficiently.

What is Cross-Docking? Warehousing Benefits & Strategies - ShipBob - Cross-docking facilities function as sorting centers that quickly route products from inbound to outbound shipments with minimal storage, using methods such as continuous cross-docking, consolidation, and deconsolidation to handle various shipping needs.

How Does Cross Docking Work in Industrial Real Estate? - A cross-docking facility typically features docks on opposite sides with a short distance between them to enable direct transfer of goods from inbound trucks to outbound trucks, reducing storage needs and improving supply chain efficiency.

dowidth.com

dowidth.com