Microfulfillment centers leverage automation to enable rapid order processing within urban areas, reducing delivery times and transportation costs. Centralized fulfillment centers consolidate large inventories in single locations, optimizing storage efficiency and bulk shipping but often extending delivery windows. Explore the advantages and challenges of each fulfillment model to determine the best fit for your retail strategy.

Why it is important

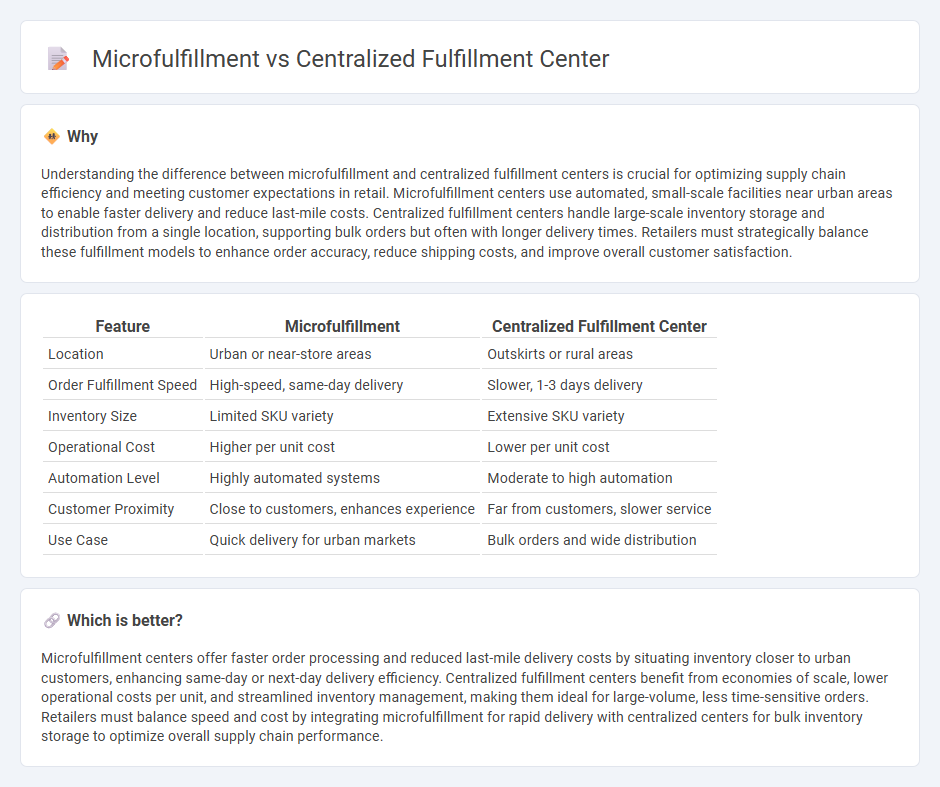

Understanding the difference between microfulfillment and centralized fulfillment centers is crucial for optimizing supply chain efficiency and meeting customer expectations in retail. Microfulfillment centers use automated, small-scale facilities near urban areas to enable faster delivery and reduce last-mile costs. Centralized fulfillment centers handle large-scale inventory storage and distribution from a single location, supporting bulk orders but often with longer delivery times. Retailers must strategically balance these fulfillment models to enhance order accuracy, reduce shipping costs, and improve overall customer satisfaction.

Comparison Table

| Feature | Microfulfillment | Centralized Fulfillment Center |

|---|---|---|

| Location | Urban or near-store areas | Outskirts or rural areas |

| Order Fulfillment Speed | High-speed, same-day delivery | Slower, 1-3 days delivery |

| Inventory Size | Limited SKU variety | Extensive SKU variety |

| Operational Cost | Higher per unit cost | Lower per unit cost |

| Automation Level | Highly automated systems | Moderate to high automation |

| Customer Proximity | Close to customers, enhances experience | Far from customers, slower service |

| Use Case | Quick delivery for urban markets | Bulk orders and wide distribution |

Which is better?

Microfulfillment centers offer faster order processing and reduced last-mile delivery costs by situating inventory closer to urban customers, enhancing same-day or next-day delivery efficiency. Centralized fulfillment centers benefit from economies of scale, lower operational costs per unit, and streamlined inventory management, making them ideal for large-volume, less time-sensitive orders. Retailers must balance speed and cost by integrating microfulfillment for rapid delivery with centralized centers for bulk inventory storage to optimize overall supply chain performance.

Connection

Microfulfillment centers and centralized fulfillment centers are interconnected by their roles in optimizing retail supply chains to enhance order accuracy and delivery speed. Microfulfillment centers utilize localized, automated storage and retrieval systems positioned close to customers, while centralized fulfillment centers manage larger inventories at a regional scale to support bulk processing. This synergy enables retailers to balance inventory availability with rapid, last-mile delivery, improving overall operational efficiency and customer satisfaction.

Key Terms

Inventory Management

Centralized fulfillment centers consolidate inventory in a single large warehouse, enabling streamlined stock control and bulk inventory management, which reduces carrying costs but may slow response times for local delivery. Microfulfillment centers distribute inventory across multiple smaller facilities closer to end customers, improving inventory turnover rates and enabling rapid replenishment, though this approach requires sophisticated real-time inventory tracking systems to avoid stockouts. Explore detailed comparisons to determine which inventory strategy best aligns with your supply chain goals.

Order Processing Speed

Centralized fulfillment centers handle large volumes of orders from a single location, often resulting in longer processing times due to batch handling and extended shipping distances. Microfulfillment centers, strategically located near urban areas, enable faster order processing by minimizing last-mile delivery challenges and enhancing real-time inventory access. Explore how these fulfillment models impact your supply chain efficiency and customer satisfaction in greater detail.

Last-Mile Delivery

Centralized fulfillment centers consolidate inventory in large warehouses, optimizing bulk processing but often facing challenges in fast last-mile delivery due to distance from end consumers. Microfulfillment centers, typically located within urban areas, leverage automation and proximity to drastically reduce delivery times and enhance customer satisfaction. Explore further to understand which model best suits your retail strategy and last-mile efficiency needs.

Source and External Links

Importance Of Centralized Fulfillment Centers For E-commerce - Centralized fulfillment centers gather inventory from multiple locations into a single hub, optimizing storage, order processing, and distribution for businesses.

Central Dist. Center: Logistics Guide | Fulfill.com Glossary - A centralized fulfillment center receives goods from suppliers, manages inventory, processes orders, and ships products directly to customers or retail outlets in a unified operation.

Regional vs. Centralized Distribution: Evaluating Approaches for Success - Centralized distribution uses a single hub for inventory, sorting, and dispatch, offering streamlined logistics and economies of scale for businesses operating over wide areas.

dowidth.com

dowidth.com