Micro fulfillment centers (MFCs) are compact, automated facilities positioned close to urban areas, speeding up order processing and delivery for retailers. Centralized fulfillment centers operate on a larger scale, consolidating inventory in a single location to optimize storage costs but may face longer transit times to customers. Explore the advantages and challenges of each fulfillment strategy to enhance your retail supply chain efficiency.

Why it is important

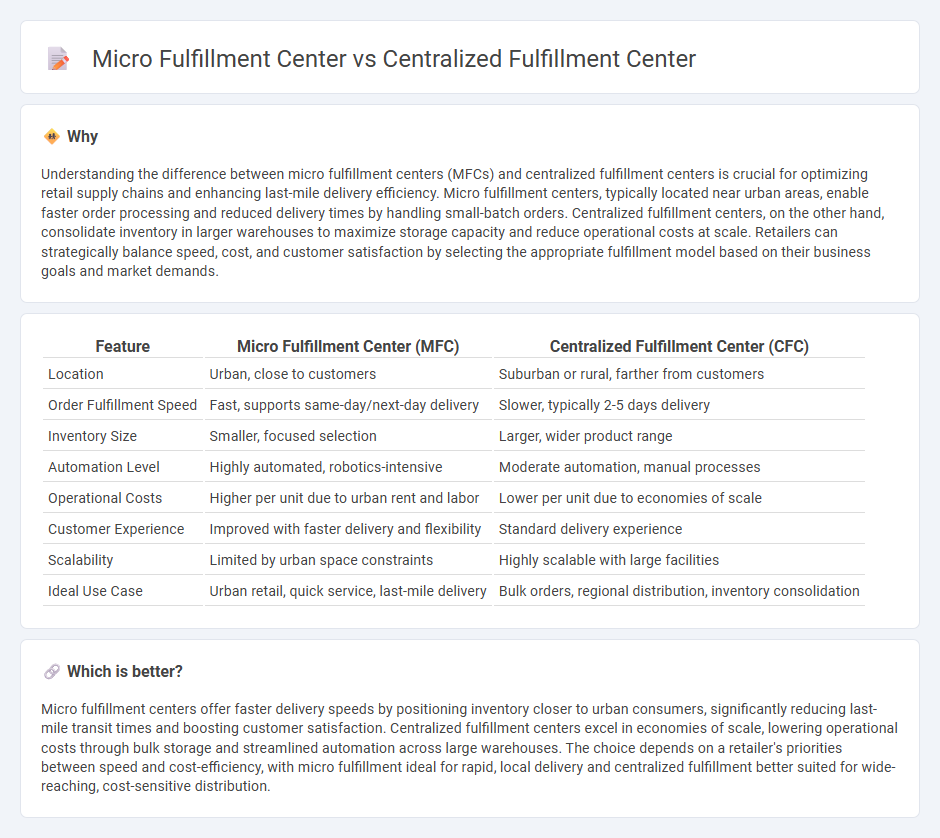

Understanding the difference between micro fulfillment centers (MFCs) and centralized fulfillment centers is crucial for optimizing retail supply chains and enhancing last-mile delivery efficiency. Micro fulfillment centers, typically located near urban areas, enable faster order processing and reduced delivery times by handling small-batch orders. Centralized fulfillment centers, on the other hand, consolidate inventory in larger warehouses to maximize storage capacity and reduce operational costs at scale. Retailers can strategically balance speed, cost, and customer satisfaction by selecting the appropriate fulfillment model based on their business goals and market demands.

Comparison Table

| Feature | Micro Fulfillment Center (MFC) | Centralized Fulfillment Center (CFC) |

|---|---|---|

| Location | Urban, close to customers | Suburban or rural, farther from customers |

| Order Fulfillment Speed | Fast, supports same-day/next-day delivery | Slower, typically 2-5 days delivery |

| Inventory Size | Smaller, focused selection | Larger, wider product range |

| Automation Level | Highly automated, robotics-intensive | Moderate automation, manual processes |

| Operational Costs | Higher per unit due to urban rent and labor | Lower per unit due to economies of scale |

| Customer Experience | Improved with faster delivery and flexibility | Standard delivery experience |

| Scalability | Limited by urban space constraints | Highly scalable with large facilities |

| Ideal Use Case | Urban retail, quick service, last-mile delivery | Bulk orders, regional distribution, inventory consolidation |

Which is better?

Micro fulfillment centers offer faster delivery speeds by positioning inventory closer to urban consumers, significantly reducing last-mile transit times and boosting customer satisfaction. Centralized fulfillment centers excel in economies of scale, lowering operational costs through bulk storage and streamlined automation across large warehouses. The choice depends on a retailer's priorities between speed and cost-efficiency, with micro fulfillment ideal for rapid, local delivery and centralized fulfillment better suited for wide-reaching, cost-sensitive distribution.

Connection

Micro fulfillment centers and centralized fulfillment centers are interconnected through an integrated supply chain network that optimizes inventory distribution and order processing. Centralized fulfillment centers store bulk inventory and manage large-scale order consolidation, while micro fulfillment centers, located closer to urban consumers, rapidly handle last-mile delivery with higher efficiency. Leveraging real-time data synchronization and advanced Automation systems ensures seamless collaboration, reducing delivery times and operational costs in the retail sector.

Key Terms

Inventory Management

Centralized fulfillment centers consolidate inventory in large warehouses, optimizing bulk storage and reducing overall stock levels through economies of scale. Micro fulfillment centers distribute inventory across smaller, strategically located facilities to enhance agility and speed in last-mile delivery, leveraging advanced inventory tracking technology for real-time stock management. Explore deeper insights into inventory management strategies for both fulfillment models to optimize supply chain efficiency.

Order Processing Speed

Centralized fulfillment centers handle large-scale order processing with expansive storage but often face slower order processing speeds due to longer picking and shipping routes. Micro fulfillment centers, strategically located near high-demand areas, significantly enhance order processing speed by reducing transit times and enabling faster pick-and-pack operations. Explore the advantages of each fulfillment model to optimize your supply chain efficiency.

Last-Mile Delivery

Centralized fulfillment centers consolidate inventory in large warehouses, optimizing storage efficiency but often increasing last-mile delivery times and costs due to greater distances from customers. Micro fulfillment centers are strategically located near urban areas, reducing delivery times and enhancing customer satisfaction by enabling faster, more flexible last-mile logistics. Explore the latest strategies and technologies improving last-mile delivery in both fulfillment models for a competitive edge.

Source and External Links

Importance Of Centralized Fulfillment Centers For E-commerce - Centralized fulfillment centers consolidate inventory from various sources into one location, optimizing storage and distribution for businesses.

Regional vs. Centralized Distribution: Evaluating Approaches for ... - Centralized distribution involves consolidating inventory and logistics activities in a single hub to achieve economies of scale and streamline shipping over large geographic areas.

Centralized or Decentralized Fulfillment? - PFS Commerce - Centralized fulfillment offers simplified inventory planning, reduces operational costs with a single stockpile, and provides accurate data for predicting consumer demand.

dowidth.com

dowidth.com