Smart shelves use sensors and RFID technology to track inventory in real-time, enhancing product visibility and reducing out-of-stock situations. Automated stock replenishment relies on AI-driven systems to predict demand and trigger restocking processes without human intervention, optimizing supply chain efficiency. Explore how integrating these technologies can transform retail operations and boost customer satisfaction.

Why it is important

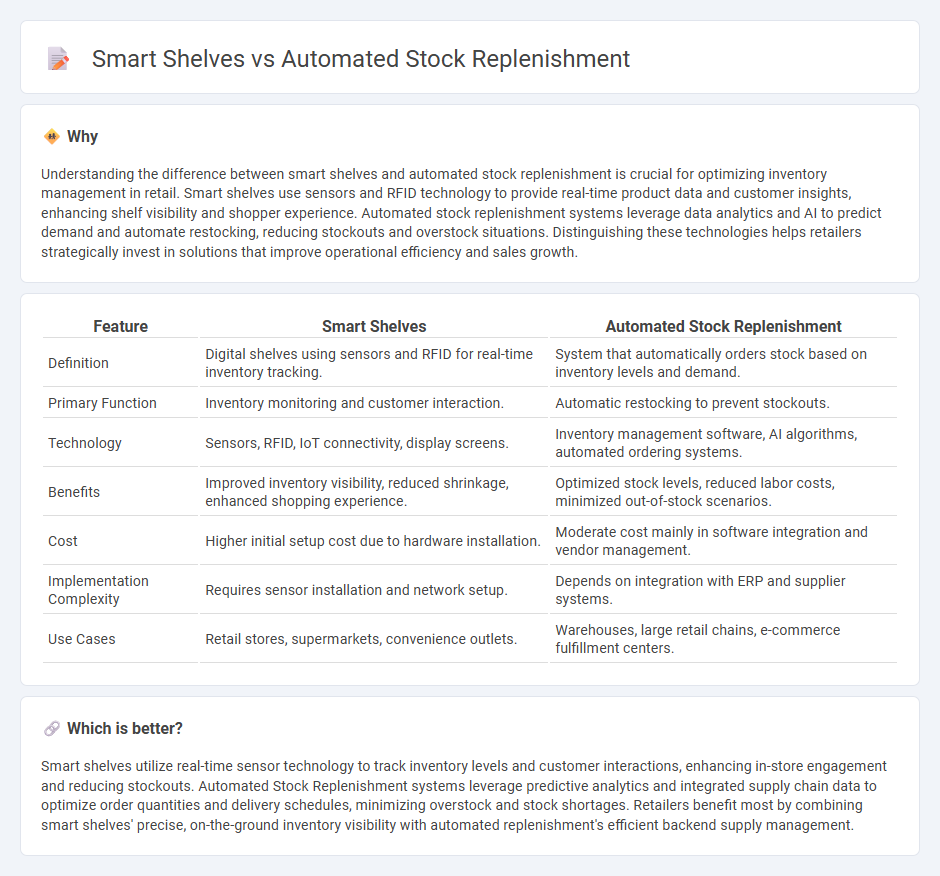

Understanding the difference between smart shelves and automated stock replenishment is crucial for optimizing inventory management in retail. Smart shelves use sensors and RFID technology to provide real-time product data and customer insights, enhancing shelf visibility and shopper experience. Automated stock replenishment systems leverage data analytics and AI to predict demand and automate restocking, reducing stockouts and overstock situations. Distinguishing these technologies helps retailers strategically invest in solutions that improve operational efficiency and sales growth.

Comparison Table

| Feature | Smart Shelves | Automated Stock Replenishment |

|---|---|---|

| Definition | Digital shelves using sensors and RFID for real-time inventory tracking. | System that automatically orders stock based on inventory levels and demand. |

| Primary Function | Inventory monitoring and customer interaction. | Automatic restocking to prevent stockouts. |

| Technology | Sensors, RFID, IoT connectivity, display screens. | Inventory management software, AI algorithms, automated ordering systems. |

| Benefits | Improved inventory visibility, reduced shrinkage, enhanced shopping experience. | Optimized stock levels, reduced labor costs, minimized out-of-stock scenarios. |

| Cost | Higher initial setup cost due to hardware installation. | Moderate cost mainly in software integration and vendor management. |

| Implementation Complexity | Requires sensor installation and network setup. | Depends on integration with ERP and supplier systems. |

| Use Cases | Retail stores, supermarkets, convenience outlets. | Warehouses, large retail chains, e-commerce fulfillment centers. |

Which is better?

Smart shelves utilize real-time sensor technology to track inventory levels and customer interactions, enhancing in-store engagement and reducing stockouts. Automated Stock Replenishment systems leverage predictive analytics and integrated supply chain data to optimize order quantities and delivery schedules, minimizing overstock and stock shortages. Retailers benefit most by combining smart shelves' precise, on-the-ground inventory visibility with automated replenishment's efficient backend supply management.

Connection

Smart shelves utilize sensors and RFID technology to monitor inventory levels in real-time, enabling automated stock replenishment systems to trigger timely restocking orders without manual intervention. These interconnected technologies reduce out-of-stock situations, optimize inventory management, and improve overall retail efficiency. Integration of smart shelves with automated replenishment supports data-driven decision-making, enhancing supply chain responsiveness and customer satisfaction.

Key Terms

Inventory Management Systems

Automated stock replenishment systems utilize real-time data and predictive algorithms to maintain optimal inventory levels, reducing stockouts and overstock situations. Smart shelves integrate sensor technology and RFID to provide instant visibility into product quantities, improving accuracy in inventory tracking and customer experience. Explore the latest advancements in inventory management systems to optimize your supply chain efficiency.

Real-time Data Analytics

Automated stock replenishment systems leverage real-time data analytics to optimize inventory levels by predicting demand and triggering timely restocks, reducing stockouts and overstock scenarios. Smart shelves integrate sensor technology with real-time analytics to monitor product availability and customer interactions, enabling dynamic pricing and improved inventory accuracy. Explore how real-time data analytics can transform retail operations by enhancing both automated stock replenishment and smart shelf technologies.

IoT Sensors

IoT sensors play a crucial role in automated stock replenishment by providing real-time inventory data, reducing stockouts and excess inventory through accurate demand forecasting. Smart shelves leverage these sensors to monitor product levels continuously, ensuring timely restocking and enhancing the customer shopping experience with up-to-date product availability. Discover how IoT sensor technology transforms inventory management and retail efficiency by exploring deeper insights.

Source and External Links

What is Auto Stock Replenishment (ARS) & Why You Need it? - Auto Stock Replenishment uses AI and machine learning to forecast demand based on past sales, enabling intelligent, fully automated ordering to maintain stock levels efficiently and reduce waste.

What is Automatic Replenishment? 8 Advantages & How-To Guide - Automatic replenishment maintains optimal stock levels by setting minimum and maximum thresholds that trigger automatic orders to avoid both stockouts and overstocking, enhancing inventory management efficiency.

Automated Supply Replenishment Systems - eTurns - Automated replenishment systems track real-time usage via barcodes or sensors to calculate optimal inventory levels, reducing carrying costs and preventing stockouts through data-driven stock control.

dowidth.com

dowidth.com