Productivity theater focuses on creating an illusion of efficiency through superficial metrics and constant activity, often leading to wasted resources and employee burnout. Lean management emphasizes value-driven processes, continuous improvement, and waste reduction to optimize operational performance and deliver genuine results. Explore how shifting from productivity theater to lean management can transform organizational success.

Why it is important

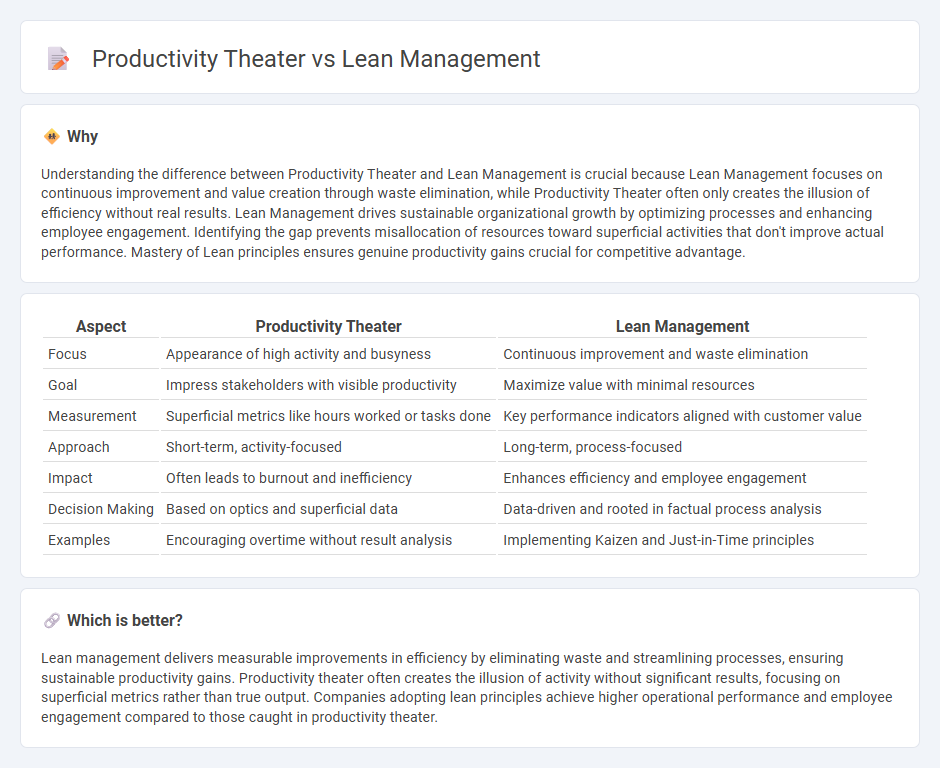

Understanding the difference between Productivity Theater and Lean Management is crucial because Lean Management focuses on continuous improvement and value creation through waste elimination, while Productivity Theater often only creates the illusion of efficiency without real results. Lean Management drives sustainable organizational growth by optimizing processes and enhancing employee engagement. Identifying the gap prevents misallocation of resources toward superficial activities that don't improve actual performance. Mastery of Lean principles ensures genuine productivity gains crucial for competitive advantage.

Comparison Table

| Aspect | Productivity Theater | Lean Management |

|---|---|---|

| Focus | Appearance of high activity and busyness | Continuous improvement and waste elimination |

| Goal | Impress stakeholders with visible productivity | Maximize value with minimal resources |

| Measurement | Superficial metrics like hours worked or tasks done | Key performance indicators aligned with customer value |

| Approach | Short-term, activity-focused | Long-term, process-focused |

| Impact | Often leads to burnout and inefficiency | Enhances efficiency and employee engagement |

| Decision Making | Based on optics and superficial data | Data-driven and rooted in factual process analysis |

| Examples | Encouraging overtime without result analysis | Implementing Kaizen and Just-in-Time principles |

Which is better?

Lean management delivers measurable improvements in efficiency by eliminating waste and streamlining processes, ensuring sustainable productivity gains. Productivity theater often creates the illusion of activity without significant results, focusing on superficial metrics rather than true output. Companies adopting lean principles achieve higher operational performance and employee engagement compared to those caught in productivity theater.

Connection

Productivity theater, characterized by superficial efficiency measures without real impact, contrasts sharply with Lean management, which emphasizes continuous improvement and waste reduction to enhance value delivery. Lean management targets root causes of inefficiencies through actionable data and standardized processes, preventing the inefficacy often seen in productivity theater. Organizations adopting Lean frameworks typically experience sustainable productivity gains by fostering a culture of transparency and employee empowerment rather than relying on performative metrics.

Key Terms

**Lean Management:**

Lean management emphasizes continuous improvement, waste reduction, and delivering value to customers through efficient processes and employee engagement. Unlike productivity theater, which relies on superficial metrics and busywork, lean focuses on measurable outcomes and sustainable operational excellence. Explore how lean management transforms organizations by driving real productivity and innovation.

Value Stream

Lean management emphasizes continuous improvement and waste elimination within the value stream to enhance operational efficiency and deliver maximum value to customers. Productivity theater, in contrast, often prioritizes superficial metrics and busywork that do not contribute to genuine value creation or process optimization. Explore the core principles and real impacts of lean management in transforming value streams for sustainable productivity gains.

Waste Elimination

Lean management prioritizes the systematic elimination of waste through continuous improvement, focusing on value stream mapping, just-in-time production, and empowering employees to identify inefficiencies. Productivity theater, on the other hand, involves superficial efforts that create the appearance of efficiency without substantial impact on waste reduction or process optimization. Discover effective strategies to distinguish genuine lean practices from productivity theater and maximize operational excellence.

Source and External Links

What is Lean Management? - Lean management is an approach to organizational management focused on continuous improvement, eliminating waste, and optimizing resources to produce value for customers.

Definition, tools and advantages of Lean Management - Lean Management is a method aimed at improving performance and profitability by streamlining processes and creating a continuous workflow based on customer demand.

Definition and Advantages of Lean Management - Lean Management is a systematic approach to improve processes by eliminating waste and maximizing customer value, utilizing tools like Six Sigma and Kaizen.

dowidth.com

dowidth.com