Intelligent automation integrates artificial intelligence and machine learning to optimize business processes by reducing manual tasks and increasing operational efficiency. Lean management focuses on eliminating waste and improving workflows through continuous improvement and value stream mapping techniques. Explore how combining intelligent automation with lean management can revolutionize your organizational performance.

Why it is important

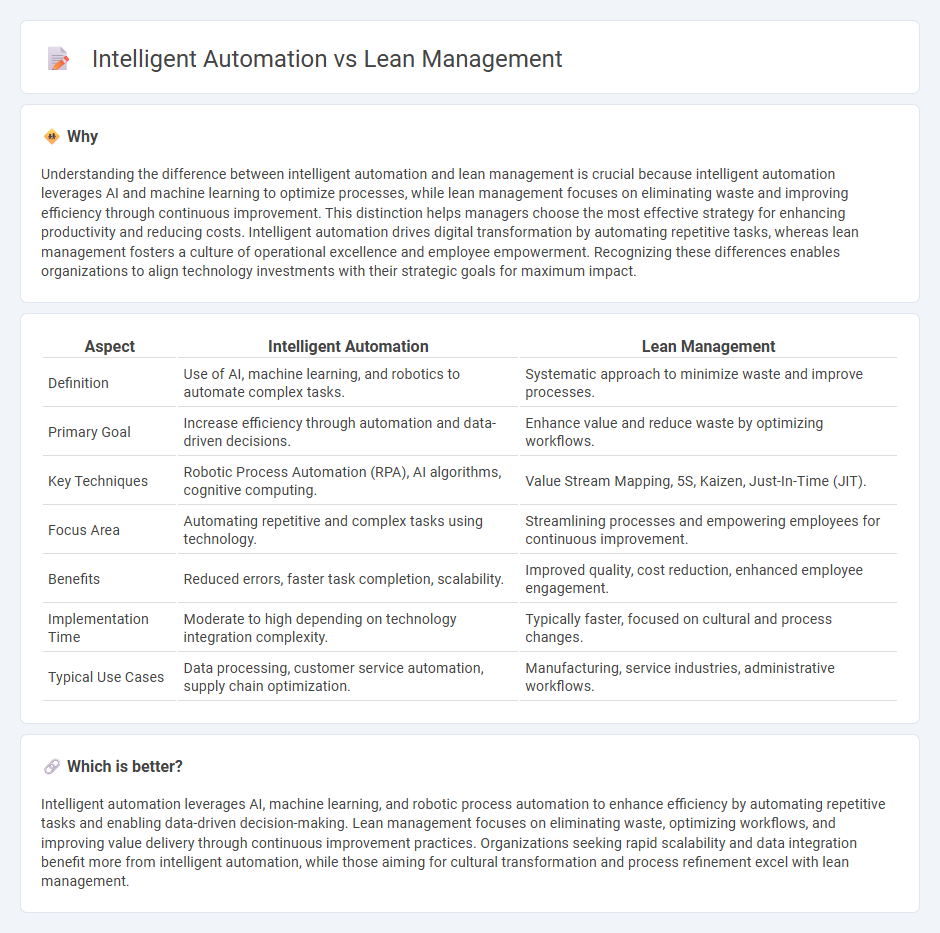

Understanding the difference between intelligent automation and lean management is crucial because intelligent automation leverages AI and machine learning to optimize processes, while lean management focuses on eliminating waste and improving efficiency through continuous improvement. This distinction helps managers choose the most effective strategy for enhancing productivity and reducing costs. Intelligent automation drives digital transformation by automating repetitive tasks, whereas lean management fosters a culture of operational excellence and employee empowerment. Recognizing these differences enables organizations to align technology investments with their strategic goals for maximum impact.

Comparison Table

| Aspect | Intelligent Automation | Lean Management |

|---|---|---|

| Definition | Use of AI, machine learning, and robotics to automate complex tasks. | Systematic approach to minimize waste and improve processes. |

| Primary Goal | Increase efficiency through automation and data-driven decisions. | Enhance value and reduce waste by optimizing workflows. |

| Key Techniques | Robotic Process Automation (RPA), AI algorithms, cognitive computing. | Value Stream Mapping, 5S, Kaizen, Just-In-Time (JIT). |

| Focus Area | Automating repetitive and complex tasks using technology. | Streamlining processes and empowering employees for continuous improvement. |

| Benefits | Reduced errors, faster task completion, scalability. | Improved quality, cost reduction, enhanced employee engagement. |

| Implementation Time | Moderate to high depending on technology integration complexity. | Typically faster, focused on cultural and process changes. |

| Typical Use Cases | Data processing, customer service automation, supply chain optimization. | Manufacturing, service industries, administrative workflows. |

Which is better?

Intelligent automation leverages AI, machine learning, and robotic process automation to enhance efficiency by automating repetitive tasks and enabling data-driven decision-making. Lean management focuses on eliminating waste, optimizing workflows, and improving value delivery through continuous improvement practices. Organizations seeking rapid scalability and data integration benefit more from intelligent automation, while those aiming for cultural transformation and process refinement excel with lean management.

Connection

Intelligent automation integrates advanced technologies like AI and machine learning to streamline workflows, reducing manual effort and errors. Lean management focuses on eliminating waste and optimizing processes, creating a culture of continuous improvement. Combining these approaches enhances operational efficiency, accelerates decision-making, and drives sustainable business performance.

Key Terms

Lean Management:

Lean Management emphasizes streamlining processes by eliminating waste, improving workflow, and enhancing value delivery to customers. It relies on principles like continuous improvement (Kaizen), just-in-time production, and employee involvement to optimize operational efficiency. Discover how Lean Management drives sustainable growth and operational excellence in your organization.

Value Stream Mapping

Lean management enhances operational efficiency by systematically identifying and eliminating waste through Value Stream Mapping, which visually represents process flows to optimize value delivery. Intelligent automation integrates advanced technologies like AI and machine learning to automate repetitive tasks within these mapped value streams, accelerating throughput and improving accuracy. Explore how combining lean management with intelligent automation can revolutionize your business processes for maximum value creation.

Continuous Improvement (Kaizen)

Lean management emphasizes Continuous Improvement (Kaizen) by systematically eliminating waste and enhancing operational processes through employee-driven incremental changes. Intelligent automation leverages advanced technologies like AI and machine learning to streamline repetitive tasks, enabling faster feedback loops and data-driven decision-making that supports continuous improvement efforts. Explore how integrating Lean principles with intelligent automation can accelerate Kaizen and drive sustainable business growth.

Source and External Links

What is Lean Management? | Definition from TechTarget - Lean management involves continuous improvement to optimize resources, eliminate waste, and create value for customers by streamlining business processes.

Definition, tools and advantages of Lean Management - Lean management enhances company performance by improving quality and profitability through continuous workflow and efficient resource allocation.

What Is Lean Management? Basics Explained - Lean management reduces waste and improves efficiency by creating smoother workflows and implementing pull systems that align with customer demand.

dowidth.com

dowidth.com