Cold chain visibility leverages real-time tracking technologies such as IoT sensors and GPS to monitor temperature-sensitive shipments, ensuring compliance with safety standards and reducing spoilage risks. Cold chain automation integrates advanced robotics and AI-driven systems to optimize handling, storage, and transportation processes, significantly increasing efficiency and accuracy. Explore how combining these innovations transforms temperature-controlled logistics management.

Why it is important

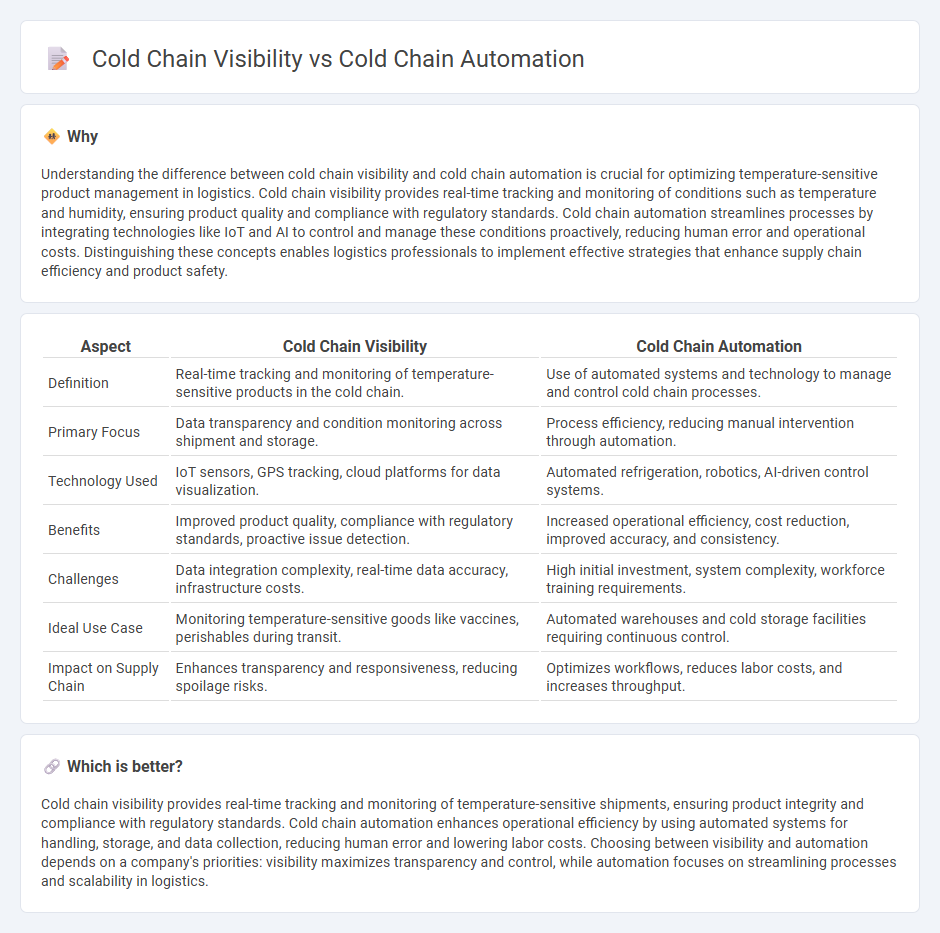

Understanding the difference between cold chain visibility and cold chain automation is crucial for optimizing temperature-sensitive product management in logistics. Cold chain visibility provides real-time tracking and monitoring of conditions such as temperature and humidity, ensuring product quality and compliance with regulatory standards. Cold chain automation streamlines processes by integrating technologies like IoT and AI to control and manage these conditions proactively, reducing human error and operational costs. Distinguishing these concepts enables logistics professionals to implement effective strategies that enhance supply chain efficiency and product safety.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Automation |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature-sensitive products in the cold chain. | Use of automated systems and technology to manage and control cold chain processes. |

| Primary Focus | Data transparency and condition monitoring across shipment and storage. | Process efficiency, reducing manual intervention through automation. |

| Technology Used | IoT sensors, GPS tracking, cloud platforms for data visualization. | Automated refrigeration, robotics, AI-driven control systems. |

| Benefits | Improved product quality, compliance with regulatory standards, proactive issue detection. | Increased operational efficiency, cost reduction, improved accuracy, and consistency. |

| Challenges | Data integration complexity, real-time data accuracy, infrastructure costs. | High initial investment, system complexity, workforce training requirements. |

| Ideal Use Case | Monitoring temperature-sensitive goods like vaccines, perishables during transit. | Automated warehouses and cold storage facilities requiring continuous control. |

| Impact on Supply Chain | Enhances transparency and responsiveness, reducing spoilage risks. | Optimizes workflows, reduces labor costs, and increases throughput. |

Which is better?

Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive shipments, ensuring product integrity and compliance with regulatory standards. Cold chain automation enhances operational efficiency by using automated systems for handling, storage, and data collection, reducing human error and lowering labor costs. Choosing between visibility and automation depends on a company's priorities: visibility maximizes transparency and control, while automation focuses on streamlining processes and scalability in logistics.

Connection

Cold chain visibility enhances real-time tracking of temperature-sensitive products, ensuring compliance and reducing spoilage risks. Cold chain automation integrates sensors and IoT devices to streamline data collection and monitoring processes. Together, these technologies optimize supply chain efficiency by improving accuracy and enabling proactive decision-making.

Key Terms

**Cold Chain Automation:**

Cold chain automation streamlines temperature-sensitive logistics by integrating IoT sensors, real-time monitoring, and automated alerts to maintain product integrity throughout storage and transportation. Enhanced automation reduces human error, accelerates response times, and improves compliance with regulatory standards like FDA and EU GDP. Discover how cold chain automation elevates operational efficiency and safeguards product quality in your supply chain.

Automated Temperature Control

Cold chain automation with Automated Temperature Control leverages advanced sensors and IoT technology to maintain precise thermal conditions during storage and transportation, reducing the risk of spoilage and enhancing compliance with regulatory standards like FDA and EU GDP. Cold chain visibility provides real-time tracking and remote monitoring but relies heavily on data interpretation rather than direct control of temperature parameters. Explore how integrating automated temperature regulation can revolutionize your cold chain management for improved product safety and operational efficiency.

Robotics/Automated Handling

Cold chain automation leverages robotics and automated handling systems to maintain precise temperature control and increase efficiency in product storage and transportation, reducing human error and contamination risks. Cold chain visibility involves real-time monitoring and data tracking to ensure transparent temperature management and compliance throughout the supply chain. Explore the latest advancements in robotic technology and smart sensors to understand how these innovations transform cold chain logistics.

Source and External Links

Cold Supply Chain Efficiency Through Digitalization - Elpro - Cold chain automation, including robotic picking, automated storage and retrieval systems (AS/RS), and smart energy management, improves operational efficiency, reduces human error and costs, enhances traceability, and increases worker safety by limiting exposure to cold environments.

Automation: A Positive Disruptor in Cold Chain Storage - Automation in cold chain storage optimizes precise temperature control, inventory management, and order fulfillment, reducing inefficiencies and error, and extending product shelf life with advanced, scalable solutions for perishable goods.

Cold Storage - SSI Schaefer - Cold chain automation systems like ASRS enable 24/7 operations in freezing conditions, maximize space utilization, lower energy and labor costs, reduce human error, and improve worker safety by replacing manual labor in cold environments with robotic solutions.

dowidth.com

dowidth.com