Diagnostic mapping focuses on identifying bottlenecks and inefficiencies within specific processes by analyzing current workflows and pinpointing issues affecting performance. Value stream mapping, on the other hand, visually represents the entire flow of materials and information required to bring a product or service to the customer, highlighting value-added and non-value-added activities. Explore the differences to determine which approach best suits your organization's improvement goals.

Why it is important

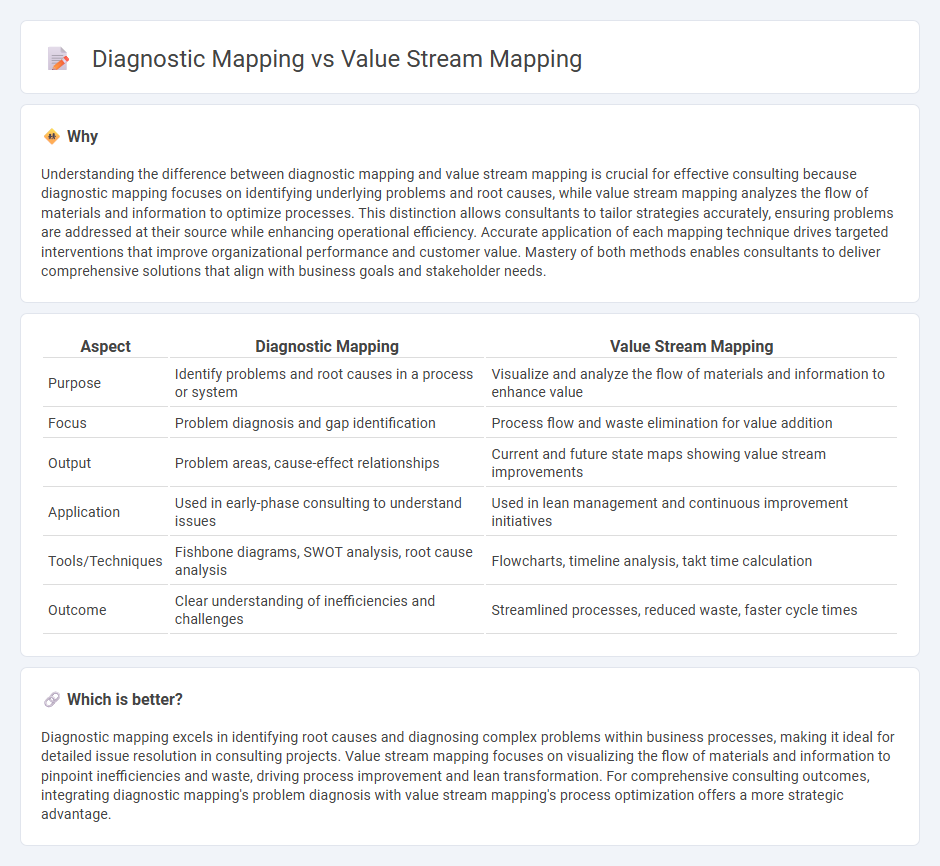

Understanding the difference between diagnostic mapping and value stream mapping is crucial for effective consulting because diagnostic mapping focuses on identifying underlying problems and root causes, while value stream mapping analyzes the flow of materials and information to optimize processes. This distinction allows consultants to tailor strategies accurately, ensuring problems are addressed at their source while enhancing operational efficiency. Accurate application of each mapping technique drives targeted interventions that improve organizational performance and customer value. Mastery of both methods enables consultants to deliver comprehensive solutions that align with business goals and stakeholder needs.

Comparison Table

| Aspect | Diagnostic Mapping | Value Stream Mapping |

|---|---|---|

| Purpose | Identify problems and root causes in a process or system | Visualize and analyze the flow of materials and information to enhance value |

| Focus | Problem diagnosis and gap identification | Process flow and waste elimination for value addition |

| Output | Problem areas, cause-effect relationships | Current and future state maps showing value stream improvements |

| Application | Used in early-phase consulting to understand issues | Used in lean management and continuous improvement initiatives |

| Tools/Techniques | Fishbone diagrams, SWOT analysis, root cause analysis | Flowcharts, timeline analysis, takt time calculation |

| Outcome | Clear understanding of inefficiencies and challenges | Streamlined processes, reduced waste, faster cycle times |

Which is better?

Diagnostic mapping excels in identifying root causes and diagnosing complex problems within business processes, making it ideal for detailed issue resolution in consulting projects. Value stream mapping focuses on visualizing the flow of materials and information to pinpoint inefficiencies and waste, driving process improvement and lean transformation. For comprehensive consulting outcomes, integrating diagnostic mapping's problem diagnosis with value stream mapping's process optimization offers a more strategic advantage.

Connection

Diagnostic mapping identifies inefficiencies and bottlenecks in business processes by analyzing current workflows, while value stream mapping visually represents these processes to highlight value-added and non-value-added activities. Both tools are connected through their focus on process improvement and operational efficiency, enabling consultants to pinpoint areas for optimization. Leveraging diagnostic mapping data enhances the accuracy of value stream maps, facilitating targeted strategies for waste reduction and performance enhancement.

Key Terms

Process Flow

Value stream mapping emphasizes visualizing the entire process flow from raw materials to finished products, highlighting value-adding and non-value-adding steps to identify waste and improve efficiency. Diagnostic mapping focuses on analyzing specific process segments to detect bottlenecks, errors, or deviations affecting overall performance and quality. Discover how these mapping techniques can optimize your process flow and drive continuous improvement.

Root Cause Analysis

Value stream mapping visually represents the entire production process to identify waste, inefficiencies, and opportunities for improvement by mapping value-added and non-value-added steps. Diagnostic mapping, in contrast, zeroes in on pinpointing root causes of specific problems through detailed analysis, often combining data collection with investigative techniques like fishbone diagrams and the 5 Whys method. Explore our detailed comparison to understand how each approach enhances root cause analysis and drives operational excellence.

Waste Identification

Value stream mapping identifies waste by visualizing end-to-end processes, highlighting delays, bottlenecks, and inefficiencies in material and information flow. Diagnostic mapping emphasizes root cause analysis, diving deeper into specific areas to uncover hidden issues and waste sources through data-driven investigation. Explore detailed methodologies and applications to enhance your waste identification strategies and improve operational efficiency.

Source and External Links

Value-stream mapping - Wikipedia - Value-stream mapping is a lean-management visual tool used to analyze and design the series of steps a product or service takes from start to customer, with the goal of identifying and eliminating waste to improve efficiency across industries including manufacturing, healthcare, and software development.

Value Stream Mapping (VSM) - Purdue University - Value stream mapping creates a visual flowchart of all people, processes, and information involved in delivering a product or service, aiding organizations in applying lean principles to reduce waste and improve overall process efficiency.

Value Stream Mapping Overview - Lean Enterprise Institute - Value-stream mapping diagrams material and information flows from order to delivery to identify and eliminate waste, typically beginning with a current state map and then designing a future state map to improve process flow, and is widely applied beyond manufacturing in many industries.

dowidth.com

dowidth.com