Digital lean transformation focuses on integrating advanced technologies and data analytics to streamline processes, enhance operational efficiency, and reduce waste within organizations. Total Quality Management (TQM) emphasizes continuous improvement through employee involvement, quality control, and customer satisfaction strategies to achieve long-term business success. Explore more to understand how these consulting approaches can revolutionize your enterprise.

Why it is important

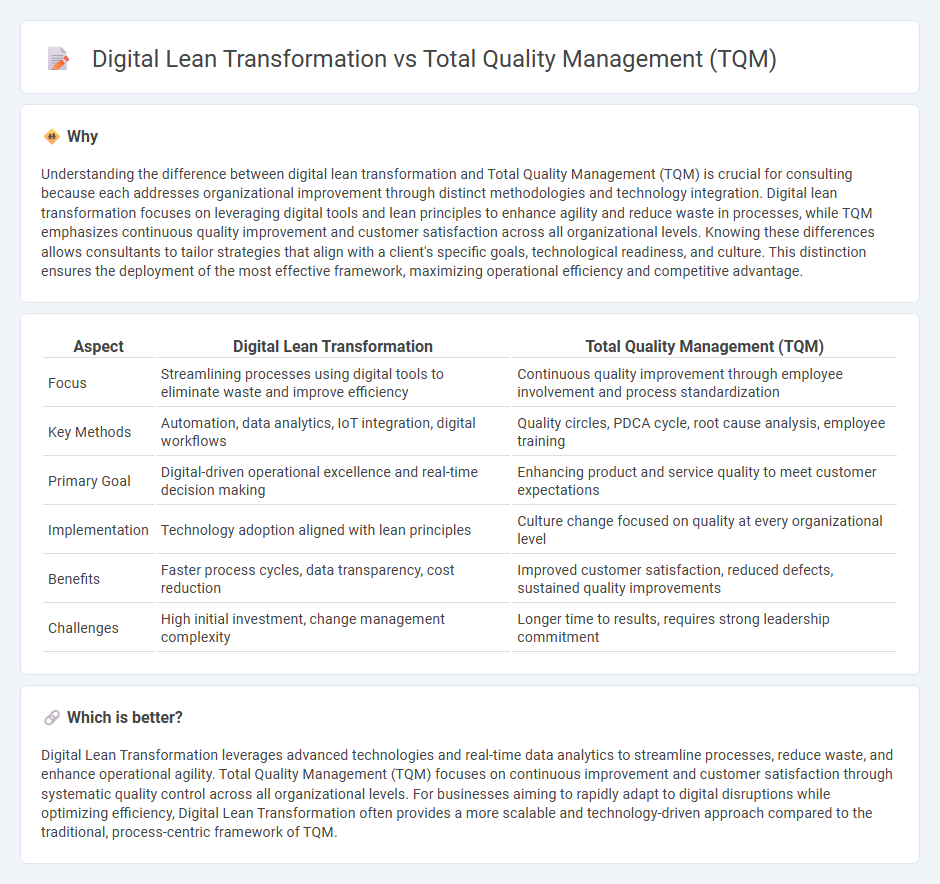

Understanding the difference between digital lean transformation and Total Quality Management (TQM) is crucial for consulting because each addresses organizational improvement through distinct methodologies and technology integration. Digital lean transformation focuses on leveraging digital tools and lean principles to enhance agility and reduce waste in processes, while TQM emphasizes continuous quality improvement and customer satisfaction across all organizational levels. Knowing these differences allows consultants to tailor strategies that align with a client's specific goals, technological readiness, and culture. This distinction ensures the deployment of the most effective framework, maximizing operational efficiency and competitive advantage.

Comparison Table

| Aspect | Digital Lean Transformation | Total Quality Management (TQM) |

|---|---|---|

| Focus | Streamlining processes using digital tools to eliminate waste and improve efficiency | Continuous quality improvement through employee involvement and process standardization |

| Key Methods | Automation, data analytics, IoT integration, digital workflows | Quality circles, PDCA cycle, root cause analysis, employee training |

| Primary Goal | Digital-driven operational excellence and real-time decision making | Enhancing product and service quality to meet customer expectations |

| Implementation | Technology adoption aligned with lean principles | Culture change focused on quality at every organizational level |

| Benefits | Faster process cycles, data transparency, cost reduction | Improved customer satisfaction, reduced defects, sustained quality improvements |

| Challenges | High initial investment, change management complexity | Longer time to results, requires strong leadership commitment |

Which is better?

Digital Lean Transformation leverages advanced technologies and real-time data analytics to streamline processes, reduce waste, and enhance operational agility. Total Quality Management (TQM) focuses on continuous improvement and customer satisfaction through systematic quality control across all organizational levels. For businesses aiming to rapidly adapt to digital disruptions while optimizing efficiency, Digital Lean Transformation often provides a more scalable and technology-driven approach compared to the traditional, process-centric framework of TQM.

Connection

Digital lean transformation and Total Quality Management (TQM) share a core focus on continuous improvement and waste reduction to enhance organizational efficiency and customer satisfaction. Digital lean transformation leverages advanced technologies like AI, IoT, and data analytics to streamline processes, aligning seamlessly with TQM's principles of quality-focused management and employee involvement. Implementing digital tools in lean practices supports real-time monitoring and decision-making, reinforcing TQM's goal of achieving consistent quality and operational excellence.

Key Terms

Continuous Improvement

Total Quality Management (TQM) emphasizes systematic processes and employee involvement for continuous improvement, aiming to enhance product quality and customer satisfaction. Digital Lean Transformation integrates advanced technologies like IoT, AI, and data analytics to streamline operations, reduce waste, and foster real-time continuous improvement. Discover how combining these strategies drives efficiency and innovation in modern businesses.

Process Automation

Process automation in Total Quality Management (TQM) emphasizes continuous improvement through standardized workflows and error reduction, while digital lean transformation leverages advanced technologies like AI and IoT to optimize efficiency and eliminate waste in real-time. TQM prioritizes quality control and employee involvement, whereas digital lean transformation integrates data analytics and automation to accelerate decision-making and operational agility. Explore how combining TQM principles with digital lean strategies can revolutionize process automation for superior business outcomes.

Value Stream Mapping

Total Quality Management (TQM) emphasizes continuous quality improvement across all organizational processes to enhance customer satisfaction and reduce defects. Digital lean transformation integrates advanced digital technologies with lean principles like Value Stream Mapping to identify and eliminate waste, optimize workflows, and accelerate value delivery. Discover how combining TQM and digital lean tools can revolutionize your operational efficiency and quality outcomes.

Source and External Links

What is Total Quality Management? | Definition from TechTarget - Total Quality Management (TQM) is a long-term management approach where all members of an organization focus on continuous internal and process improvements to enhance product or service quality and customer satisfaction.

Total Quality Management (TQM) - Corporate Finance Institute - TQM is a comprehensive organizational management philosophy emphasizing continuous improvement, teamwork, and aligning all departments around the goal of customer satisfaction by eliminating defects and improving operations.

Mastering the 8 Principles of TQM (Total Quality Management) - TQM is guided by eight core principles including leadership, client focus, continuous improvement, and evidence-based decisions, requiring cultural change and team collaboration to optimize performance and sustain competitive advantage.

dowidth.com

dowidth.com