Consulting for go-to-market acceleration focuses on rapid market entry and revenue growth through strategic customer targeting, tailored value propositions, and streamlined sales processes. Supply chain optimization consulting enhances operational efficiency by reducing costs, improving inventory management, and increasing supply chain visibility. Explore tailored consulting solutions to accelerate your market success or optimize your supply chain performance.

Why it is important

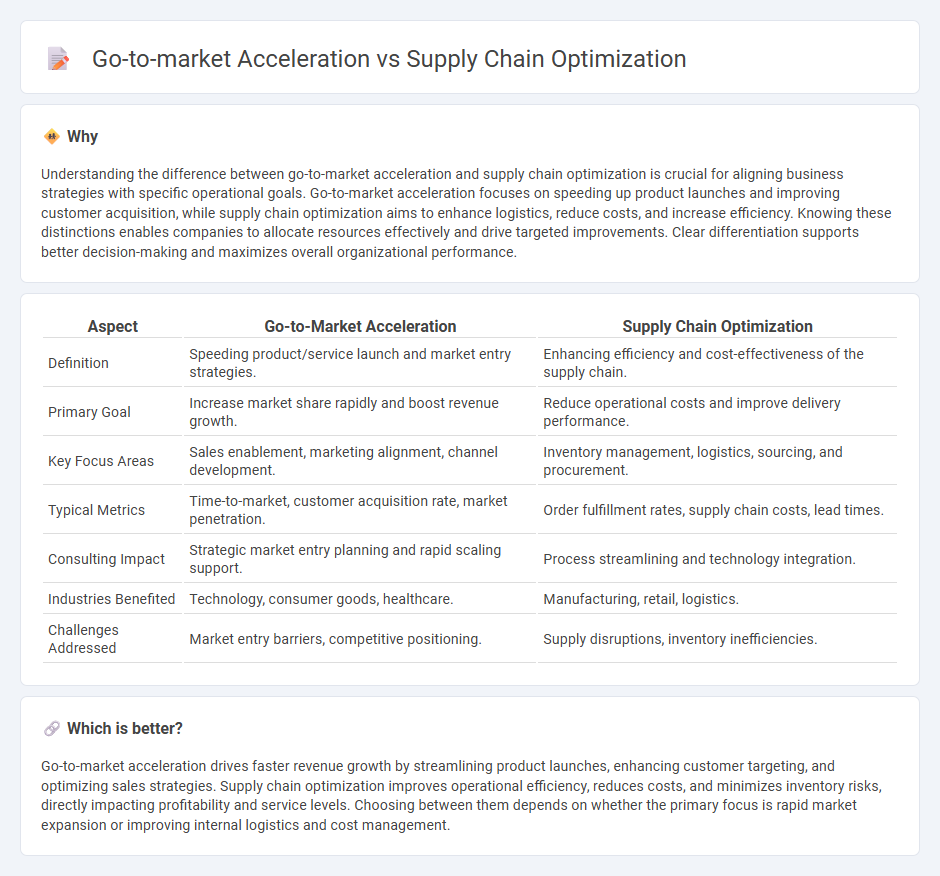

Understanding the difference between go-to-market acceleration and supply chain optimization is crucial for aligning business strategies with specific operational goals. Go-to-market acceleration focuses on speeding up product launches and improving customer acquisition, while supply chain optimization aims to enhance logistics, reduce costs, and increase efficiency. Knowing these distinctions enables companies to allocate resources effectively and drive targeted improvements. Clear differentiation supports better decision-making and maximizes overall organizational performance.

Comparison Table

| Aspect | Go-to-Market Acceleration | Supply Chain Optimization |

|---|---|---|

| Definition | Speeding product/service launch and market entry strategies. | Enhancing efficiency and cost-effectiveness of the supply chain. |

| Primary Goal | Increase market share rapidly and boost revenue growth. | Reduce operational costs and improve delivery performance. |

| Key Focus Areas | Sales enablement, marketing alignment, channel development. | Inventory management, logistics, sourcing, and procurement. |

| Typical Metrics | Time-to-market, customer acquisition rate, market penetration. | Order fulfillment rates, supply chain costs, lead times. |

| Consulting Impact | Strategic market entry planning and rapid scaling support. | Process streamlining and technology integration. |

| Industries Benefited | Technology, consumer goods, healthcare. | Manufacturing, retail, logistics. |

| Challenges Addressed | Market entry barriers, competitive positioning. | Supply disruptions, inventory inefficiencies. |

Which is better?

Go-to-market acceleration drives faster revenue growth by streamlining product launches, enhancing customer targeting, and optimizing sales strategies. Supply chain optimization improves operational efficiency, reduces costs, and minimizes inventory risks, directly impacting profitability and service levels. Choosing between them depends on whether the primary focus is rapid market expansion or improving internal logistics and cost management.

Connection

Go-to-market acceleration relies on supply chain optimization to ensure rapid product availability and timely delivery, enhancing market responsiveness and customer satisfaction. Efficient supply chains reduce lead times and costs, enabling faster product launches and adaptive marketing strategies. Integrating supply chain analytics with go-to-market plans drives competitive advantage by aligning production capabilities with dynamic market demands.

Key Terms

Supply chain optimization:

Supply chain optimization enhances operational efficiency by streamlining procurement, reducing inventory costs, and improving demand forecasting using advanced analytics and automation technologies. It directly impacts profitability by minimizing waste and accelerating product delivery timelines across global logistics networks. Explore in-depth strategies for maximizing supply chain performance and driving sustainable business growth.

Demand forecasting

Demand forecasting plays a critical role in supply chain optimization by improving inventory management, reducing lead times, and minimizing stockouts through accurate prediction of consumer demand. In go-to-market acceleration, demand forecasting enables businesses to align marketing efforts, sales strategies, and product launches with anticipated market needs, enhancing customer satisfaction and revenue growth. Explore how advanced demand forecasting techniques can transform both supply chain efficiency and market responsiveness for your business.

Inventory management

Supply chain optimization enhances inventory management by improving demand forecasting, reducing stockouts, and minimizing excess inventory, which lowers carrying costs and boosts overall efficiency. Go-to-market acceleration emphasizes rapid inventory turnover and agile distribution to meet customer demand swiftly, ensuring faster product availability and competitive advantage. Discover more about how integrating these strategies can transform your inventory management and business performance.

Source and External Links

The Ultimate Guide to Supply Chain Optimization - Order.co - Supply chain optimization improves efficiency and quality using tactics like assessing current practices, improving planning, ongoing negotiation, expanding analytics, and automation to reduce costs and enhance performance.

What is Supply Chain Optimization? - Tibco - Supply chain optimization adjusts operations to peak efficiency focusing on cost, inventory, and network optimization to reduce costs, manage quality, and adapt strategically to changes.

What Is Supply Chain Optimization? - IBM - It involves using technologies like AI, blockchain, and IoT across phases--network design, planning, and execution--to maximize efficiency, meet customer demand profitably, and support supply chain sustainability.

dowidth.com

dowidth.com