Operational excellence mapping focuses on streamlining internal processes to enhance efficiency, reduce waste, and improve overall organizational performance. Supply chain mapping emphasizes visualizing and analyzing the flow of goods, information, and finances across suppliers, manufacturers, and distributors to optimize logistics and reduce costs. Discover how these distinct methodologies can transform your business strategy and drive sustainable growth.

Why it is important

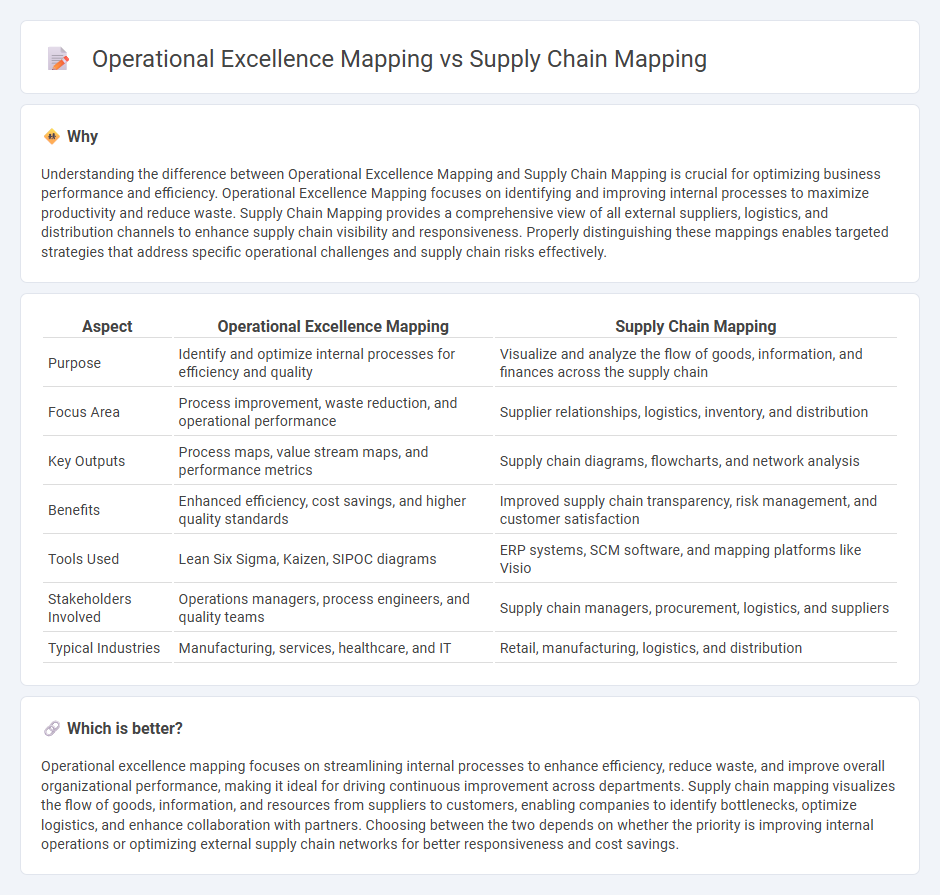

Understanding the difference between Operational Excellence Mapping and Supply Chain Mapping is crucial for optimizing business performance and efficiency. Operational Excellence Mapping focuses on identifying and improving internal processes to maximize productivity and reduce waste. Supply Chain Mapping provides a comprehensive view of all external suppliers, logistics, and distribution channels to enhance supply chain visibility and responsiveness. Properly distinguishing these mappings enables targeted strategies that address specific operational challenges and supply chain risks effectively.

Comparison Table

| Aspect | Operational Excellence Mapping | Supply Chain Mapping |

|---|---|---|

| Purpose | Identify and optimize internal processes for efficiency and quality | Visualize and analyze the flow of goods, information, and finances across the supply chain |

| Focus Area | Process improvement, waste reduction, and operational performance | Supplier relationships, logistics, inventory, and distribution |

| Key Outputs | Process maps, value stream maps, and performance metrics | Supply chain diagrams, flowcharts, and network analysis |

| Benefits | Enhanced efficiency, cost savings, and higher quality standards | Improved supply chain transparency, risk management, and customer satisfaction |

| Tools Used | Lean Six Sigma, Kaizen, SIPOC diagrams | ERP systems, SCM software, and mapping platforms like Visio |

| Stakeholders Involved | Operations managers, process engineers, and quality teams | Supply chain managers, procurement, logistics, and suppliers |

| Typical Industries | Manufacturing, services, healthcare, and IT | Retail, manufacturing, logistics, and distribution |

Which is better?

Operational excellence mapping focuses on streamlining internal processes to enhance efficiency, reduce waste, and improve overall organizational performance, making it ideal for driving continuous improvement across departments. Supply chain mapping visualizes the flow of goods, information, and resources from suppliers to customers, enabling companies to identify bottlenecks, optimize logistics, and enhance collaboration with partners. Choosing between the two depends on whether the priority is improving internal operations or optimizing external supply chain networks for better responsiveness and cost savings.

Connection

Operational excellence mapping enhances Supply Chain Mapping by identifying inefficiencies and aligning processes for streamlined workflows, reducing costs, and improving delivery speed. Both methodologies leverage data analytics and process visualization to pinpoint bottlenecks and optimize resource allocation, fostering seamless coordination between suppliers, manufacturers, and distributors. Integrating these maps ensures comprehensive visibility, enabling strategic decision-making that drives continuous improvement and sustainable competitive advantage in the supply chain.

Key Terms

Value Stream Mapping

Value Stream Mapping (VSM) is a key tool in both Supply Chain Mapping and Operational Excellence Mapping, focusing on visualizing and analyzing the flow of materials and information across the entire production process to identify waste and optimize value delivery. In Supply Chain Mapping, VSM highlights the interconnected steps from supplier to customer, emphasizing inventory levels, lead times, and process bottlenecks to enhance supply chain efficiency. Explore how leveraging Value Stream Mapping can drive continuous improvement and operational excellence in your business processes.

Process Optimization

Supply chain mapping visualizes the end-to-end flow of goods, information, and finances, identifying bottlenecks and enhancing supplier collaboration for improved efficiency. Operational excellence mapping targets internal processes to streamline workflows, reduce waste, and optimize resource utilization within the organization. Explore in-depth strategies to leverage both mappings for superior process optimization and competitive advantage.

Bottleneck Analysis

Supply chain mapping visualizes the flow of materials and information across suppliers, manufacturers, and distributors to identify bottlenecks that delay product delivery or increase costs. Operational excellence mapping emphasizes process efficiency, using bottleneck analysis to uncover constraints in production or workflow that reduce overall performance and quality. Explore advanced strategies for integrating both mapping techniques to enhance bottleneck resolution and boost organizational effectiveness.

Source and External Links

Supply chain mapping: What is it and why is it important? - This webpage provides a step-by-step guide on how to map your supply chain, emphasizing the importance of understanding your suppliers and their operations.

A Comprehensive Guide to Supply Chain Mapping in 2025 - This guide offers a detailed breakdown of the supply chain mapping process, focusing on identifying components, collecting data, and using analytics tools.

Supply Chain Mapping -- an Essential Step Toward Resilience - This article highlights the critical role of supply chain mapping in building resilience by documenting all processes and relationships within a business's supply network.

dowidth.com

dowidth.com