Digital lean transformation focuses on integrating advanced technologies and data analytics to optimize processes, reduce waste, and enhance operational efficiency in real-time. Six Sigma implementation emphasizes data-driven methodologies and statistical tools to minimize defects and improve quality control systematically. Explore how combining digital lean transformation with Six Sigma can drive superior business performance.

Why it is important

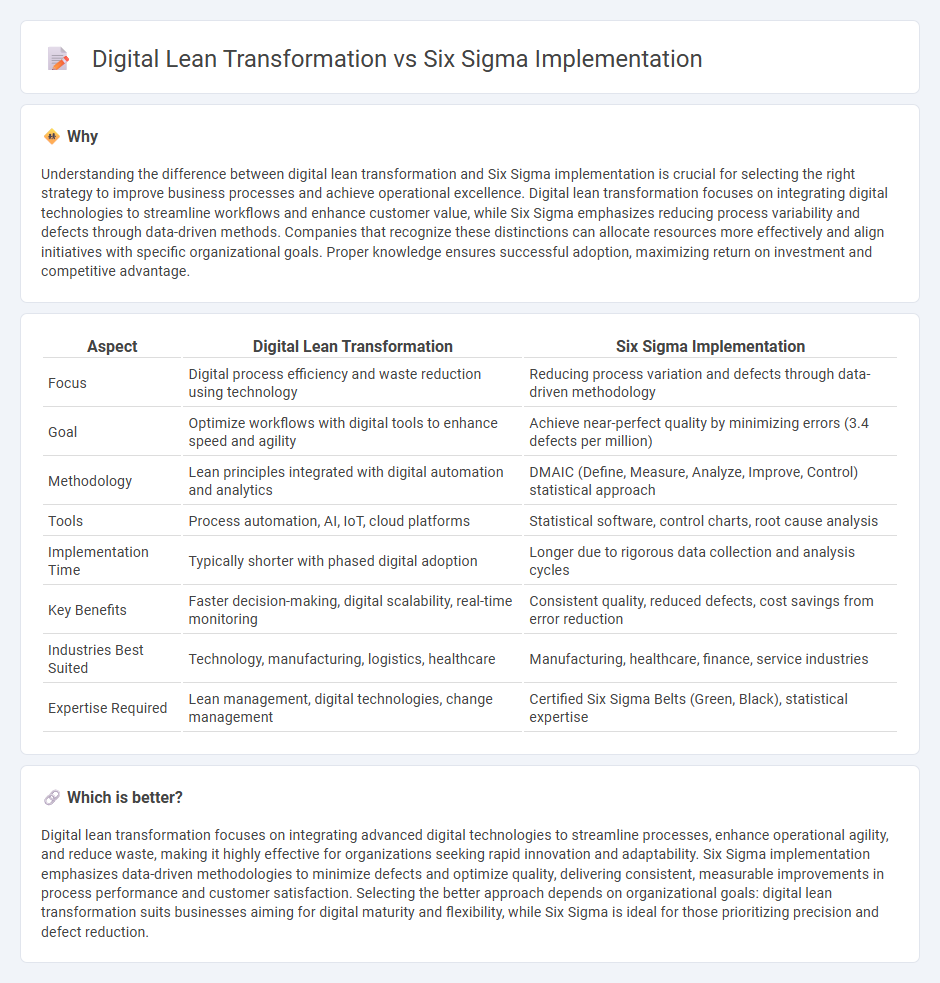

Understanding the difference between digital lean transformation and Six Sigma implementation is crucial for selecting the right strategy to improve business processes and achieve operational excellence. Digital lean transformation focuses on integrating digital technologies to streamline workflows and enhance customer value, while Six Sigma emphasizes reducing process variability and defects through data-driven methods. Companies that recognize these distinctions can allocate resources more effectively and align initiatives with specific organizational goals. Proper knowledge ensures successful adoption, maximizing return on investment and competitive advantage.

Comparison Table

| Aspect | Digital Lean Transformation | Six Sigma Implementation |

|---|---|---|

| Focus | Digital process efficiency and waste reduction using technology | Reducing process variation and defects through data-driven methodology |

| Goal | Optimize workflows with digital tools to enhance speed and agility | Achieve near-perfect quality by minimizing errors (3.4 defects per million) |

| Methodology | Lean principles integrated with digital automation and analytics | DMAIC (Define, Measure, Analyze, Improve, Control) statistical approach |

| Tools | Process automation, AI, IoT, cloud platforms | Statistical software, control charts, root cause analysis |

| Implementation Time | Typically shorter with phased digital adoption | Longer due to rigorous data collection and analysis cycles |

| Key Benefits | Faster decision-making, digital scalability, real-time monitoring | Consistent quality, reduced defects, cost savings from error reduction |

| Industries Best Suited | Technology, manufacturing, logistics, healthcare | Manufacturing, healthcare, finance, service industries |

| Expertise Required | Lean management, digital technologies, change management | Certified Six Sigma Belts (Green, Black), statistical expertise |

Which is better?

Digital lean transformation focuses on integrating advanced digital technologies to streamline processes, enhance operational agility, and reduce waste, making it highly effective for organizations seeking rapid innovation and adaptability. Six Sigma implementation emphasizes data-driven methodologies to minimize defects and optimize quality, delivering consistent, measurable improvements in process performance and customer satisfaction. Selecting the better approach depends on organizational goals: digital lean transformation suits businesses aiming for digital maturity and flexibility, while Six Sigma is ideal for those prioritizing precision and defect reduction.

Connection

Digital lean transformation and Six Sigma implementation are connected through their shared goal of enhancing operational efficiency and reducing waste. Digital lean transformation leverages advanced technologies such as AI, IoT, and data analytics to streamline processes, while Six Sigma uses statistical methods to identify and eliminate defects. Integrating these approaches results in a data-driven, technology-enabled continuous improvement strategy that drives measurable business performance improvements.

Key Terms

DMAIC

Six Sigma implementation centers on the DMAIC (Define, Measure, Analyze, Improve, Control) framework to systematically reduce defects and improve process quality through data-driven decision making. Digital Lean transformation integrates Lean principles with advanced digital technologies like IoT, AI, and big data analytics to enhance process efficiency, agility, and customer value in real-time environments. Explore how combining DMAIC with digital tools can revolutionize your operational excellence initiatives.

Value Stream Mapping

Six Sigma implementation emphasizes reducing process variation and defects through statistical analysis, while digital lean transformation integrates technology to optimize workflows and enhance value stream mapping by providing real-time data visualization. Value stream mapping in digital lean transformation leverages software tools to identify bottlenecks and waste more efficiently, enabling rapid continuous improvement cycles. Explore how combining Six Sigma methodologies with digital lean tools can maximize operational excellence and value creation.

Digital Twin

Six Sigma implementation emphasizes data-driven quality improvement by reducing defects and variability in manufacturing processes, whereas digital lean transformation integrates advanced digital technologies like Digital Twin to simulate, analyze, and optimize production in real-time. Digital Twin technology creates virtual replicas of physical assets, enabling predictive maintenance, enhanced process control, and accelerated decision-making within lean frameworks. Explore how leveraging Digital Twin can elevate your organization's operational efficiency and digital transformation journey.

Source and External Links

Complete Guide to Six Sigma Steps for Process Improvement - Six Sigma is implemented through the DMAIC method: define process problems, measure current performance, analyze data for root causes, improve the process, and control to sustain gains.

How To Implement Six Sigma: Step-by-Step Guide for Success - Effective Six Sigma implementation requires creating urgency, assigning clear ownership, building measurement systems, and establishing governance to maintain program momentum.

What Are the 7 Steps To Successful Lean Six Sigma Implementation? - Lean Six Sigma implementation involves securing leadership support, raising awareness, defining customer value, setting clear responsibilities, collecting detailed data, and using value stream mapping to target non-value-adding activities.

dowidth.com

dowidth.com