Digital twin simulation creates a virtual replica of physical processes to predict performance and identify inefficiencies through real-time data integration. Process mining analyzes event logs to uncover hidden workflow patterns and optimize operational processes by revealing bottlenecks and deviations. Explore how both methodologies enhance decision-making and drive digital transformation in consulting.

Why it is important

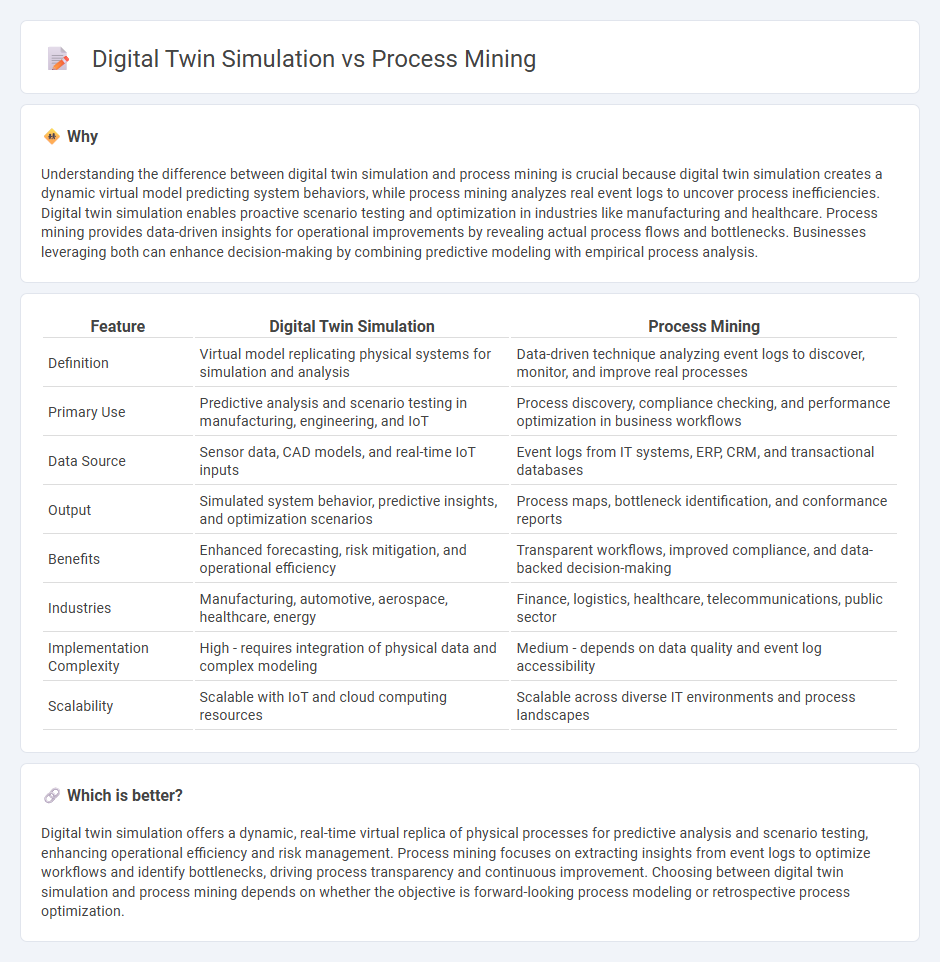

Understanding the difference between digital twin simulation and process mining is crucial because digital twin simulation creates a dynamic virtual model predicting system behaviors, while process mining analyzes real event logs to uncover process inefficiencies. Digital twin simulation enables proactive scenario testing and optimization in industries like manufacturing and healthcare. Process mining provides data-driven insights for operational improvements by revealing actual process flows and bottlenecks. Businesses leveraging both can enhance decision-making by combining predictive modeling with empirical process analysis.

Comparison Table

| Feature | Digital Twin Simulation | Process Mining |

|---|---|---|

| Definition | Virtual model replicating physical systems for simulation and analysis | Data-driven technique analyzing event logs to discover, monitor, and improve real processes |

| Primary Use | Predictive analysis and scenario testing in manufacturing, engineering, and IoT | Process discovery, compliance checking, and performance optimization in business workflows |

| Data Source | Sensor data, CAD models, and real-time IoT inputs | Event logs from IT systems, ERP, CRM, and transactional databases |

| Output | Simulated system behavior, predictive insights, and optimization scenarios | Process maps, bottleneck identification, and conformance reports |

| Benefits | Enhanced forecasting, risk mitigation, and operational efficiency | Transparent workflows, improved compliance, and data-backed decision-making |

| Industries | Manufacturing, automotive, aerospace, healthcare, energy | Finance, logistics, healthcare, telecommunications, public sector |

| Implementation Complexity | High - requires integration of physical data and complex modeling | Medium - depends on data quality and event log accessibility |

| Scalability | Scalable with IoT and cloud computing resources | Scalable across diverse IT environments and process landscapes |

Which is better?

Digital twin simulation offers a dynamic, real-time virtual replica of physical processes for predictive analysis and scenario testing, enhancing operational efficiency and risk management. Process mining focuses on extracting insights from event logs to optimize workflows and identify bottlenecks, driving process transparency and continuous improvement. Choosing between digital twin simulation and process mining depends on whether the objective is forward-looking process modeling or retrospective process optimization.

Connection

Digital twin simulation and process mining are interconnected through their ability to enhance operational efficiencies by providing real-time insights and data-driven models. Process mining extracts and analyzes event logs from IT systems to identify bottlenecks and process deviations, while digital twin simulation uses this data to create dynamic virtual replicas of physical processes for testing scenarios and optimizations. Integrating these technologies enables organizations to continuously monitor, predict, and improve workflows, driving informed decision-making and strategic process improvements.

Key Terms

Event Log Analysis

Event Log Analysis is crucial in Process Mining for extracting accurate insights from real-time data generated by IT systems, enabling detailed understanding of process flow and bottlenecks. In contrast, digital twin simulation uses virtual replicas to model and predict process behavior, often relying on synthetic or historical data rather than direct event logs. Explore how integrating Event Log Analysis enhances the precision of both technologies and drives smarter process optimization.

Virtual Modeling

Process mining extracts actionable insights from event logs to optimize workflows, while digital twin simulation creates a virtual replica of physical systems for dynamic scenario testing. Virtual modeling in digital twins enables real-time monitoring and predictive analytics, offering a more interactive and comprehensive system representation. Explore deeper into how virtual modeling enhances operational efficiency through integrated process mining and digital twin technologies.

Real-time Process Monitoring

Process Mining leverages event logs from IT systems to provide accurate real-time process monitoring, enabling identification of bottlenecks and deviations instantly. Digital Twin Simulation creates a virtual replica of processes for scenario analysis but typically lacks real-time data integration for continuous monitoring. Explore more to understand which approach best suits your real-time process optimization needs.

Source and External Links

What is Process Mining: Examples, Benefits, Types - Process mining is a data-driven technique that uses event log data from information systems to automatically discover, analyze, and improve business processes by revealing bottlenecks, inefficiencies, and deviations from expected workflows through four key steps: data preparation, discovery and analysis, enhancement, and monitoring.

What is Process Mining? | IBM - Process mining applies specialized algorithms to event log data from enterprise systems to discover and validate workflows, identify process variations and bottlenecks, and provide insights to optimize operations and facilitate automation such as robotic process automation (RPA).

What is process mining? - Process mining involves three main techniques--discovery, conformance, and enhancement--and uses event logs to create or improve process models and ensure processes conform to intended workflows, helping organizations identify redundancies and inefficiencies for operational optimization.

dowidth.com

dowidth.com