Innovation audits focus on evaluating a company's capacity to develop new products, services, and business models by examining creativity processes, idea management, and R&D investments. Operational efficiency audits assess the effectiveness of current workflows, resource utilization, and cost management to improve productivity and reduce waste. Explore how integrating both audits can drive sustainable growth and competitive advantage.

Why it is important

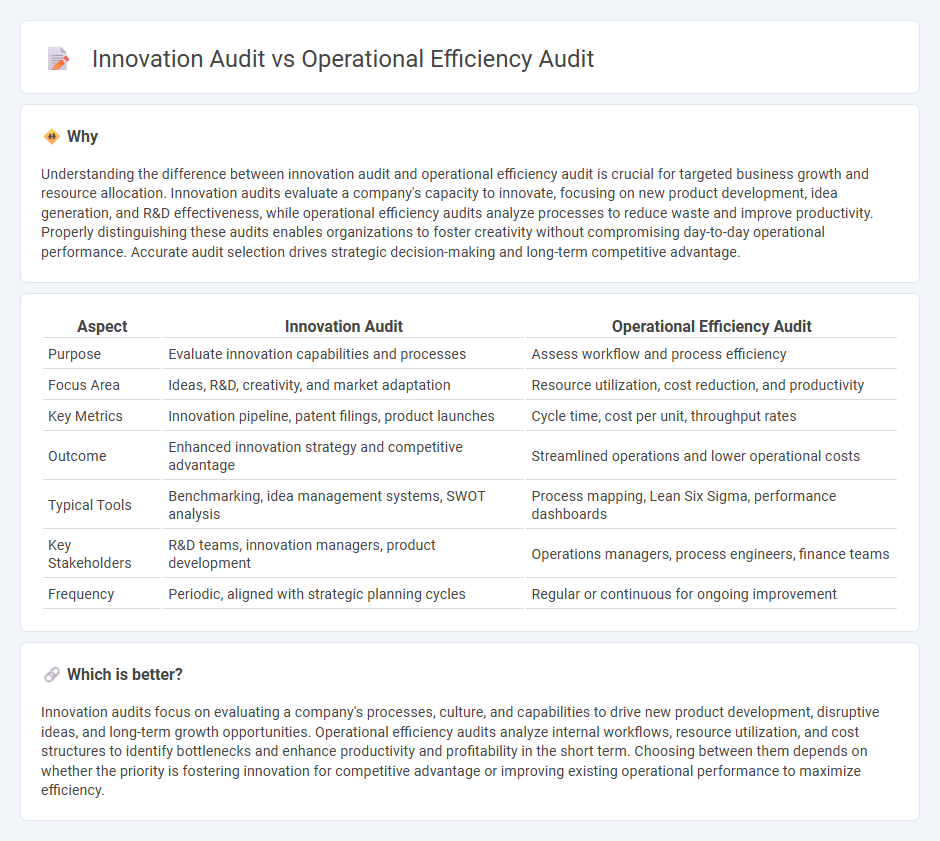

Understanding the difference between innovation audit and operational efficiency audit is crucial for targeted business growth and resource allocation. Innovation audits evaluate a company's capacity to innovate, focusing on new product development, idea generation, and R&D effectiveness, while operational efficiency audits analyze processes to reduce waste and improve productivity. Properly distinguishing these audits enables organizations to foster creativity without compromising day-to-day operational performance. Accurate audit selection drives strategic decision-making and long-term competitive advantage.

Comparison Table

| Aspect | Innovation Audit | Operational Efficiency Audit |

|---|---|---|

| Purpose | Evaluate innovation capabilities and processes | Assess workflow and process efficiency |

| Focus Area | Ideas, R&D, creativity, and market adaptation | Resource utilization, cost reduction, and productivity |

| Key Metrics | Innovation pipeline, patent filings, product launches | Cycle time, cost per unit, throughput rates |

| Outcome | Enhanced innovation strategy and competitive advantage | Streamlined operations and lower operational costs |

| Typical Tools | Benchmarking, idea management systems, SWOT analysis | Process mapping, Lean Six Sigma, performance dashboards |

| Key Stakeholders | R&D teams, innovation managers, product development | Operations managers, process engineers, finance teams |

| Frequency | Periodic, aligned with strategic planning cycles | Regular or continuous for ongoing improvement |

Which is better?

Innovation audits focus on evaluating a company's processes, culture, and capabilities to drive new product development, disruptive ideas, and long-term growth opportunities. Operational efficiency audits analyze internal workflows, resource utilization, and cost structures to identify bottlenecks and enhance productivity and profitability in the short term. Choosing between them depends on whether the priority is fostering innovation for competitive advantage or improving existing operational performance to maximize efficiency.

Connection

Innovation audits assess a company's ability to generate and implement new ideas, while operational efficiency audits evaluate the effectiveness of existing processes and resource utilization. Both audits identify gaps and opportunities that drive continuous improvement, aligning innovation initiatives with streamlined operations. Integrating insights from these audits enables organizations to optimize performance, reduce costs, and sustain competitive advantage.

Key Terms

**Operational Efficiency Audit:**

An Operational Efficiency Audit evaluates the effectiveness and productivity of business processes to identify bottlenecks, reduce costs, and streamline workflows. It emphasizes resource utilization, process optimization, and performance metrics to enhance overall operational performance. Explore detailed strategies and benefits to maximize your organization's efficiency through an Operational Efficiency Audit.

Process Optimization

Operational efficiency audits prioritize streamlining workflows, reducing waste, and enhancing resource utilization to boost productivity and lower costs. Innovation audits emphasize evaluating the organization's capacity to generate, manage, and implement new ideas that drive market differentiation and long-term growth. Explore how combining process optimization with innovation strategies can transform your business performance.

Resource Utilization

Operational efficiency audits concentrate on maximizing resource utilization by analyzing workflows, minimizing waste, and improving cost-effectiveness through process optimization. Innovation audits assess the effectiveness of resource allocation toward research and development, creative processes, and new product initiatives to drive growth and competitive advantage. Explore how aligning resource utilization with strategic goals can enhance both operational excellence and innovative capacity.

Source and External Links

Operational Excellence: the audit that wakes up your processes - An operational efficiency audit is a detailed assessment of a company's processes and performance, using tools like SWOT analysis, Ishikawa diagrams, and benchmarking to identify areas for improvement and optimize operational performance through phases such as data collection, process analysis, and reporting.

Operational auditing - Wikipedia - Operational audit is a systematic, future-oriented evaluation of a company's effectiveness, efficiency, and economy of operations, involving preparation, field survey, audit execution, and reporting, aimed at identifying opportunities for improvement with management involvement.

Operational Audit: Overview and Guide - AuditBoard - An operational audit examines internal controls, policies, procedures, and resource management to uncover inefficiencies and compliance issues, offering recommendations that help streamline processes, reduce risks and enhance overall organizational effectiveness.

dowidth.com

dowidth.com