Hyperautomation strategy leverages advanced technologies like artificial intelligence, machine learning, and robotic process automation to streamline complex business processes, offering agility and scalability beyond traditional methods. Lean Six Sigma implementation focuses on reducing waste and improving quality through data-driven process optimization and statistical analysis, emphasizing incremental improvements. Explore how integrating both approaches can maximize operational efficiency and drive sustainable business transformation.

Why it is important

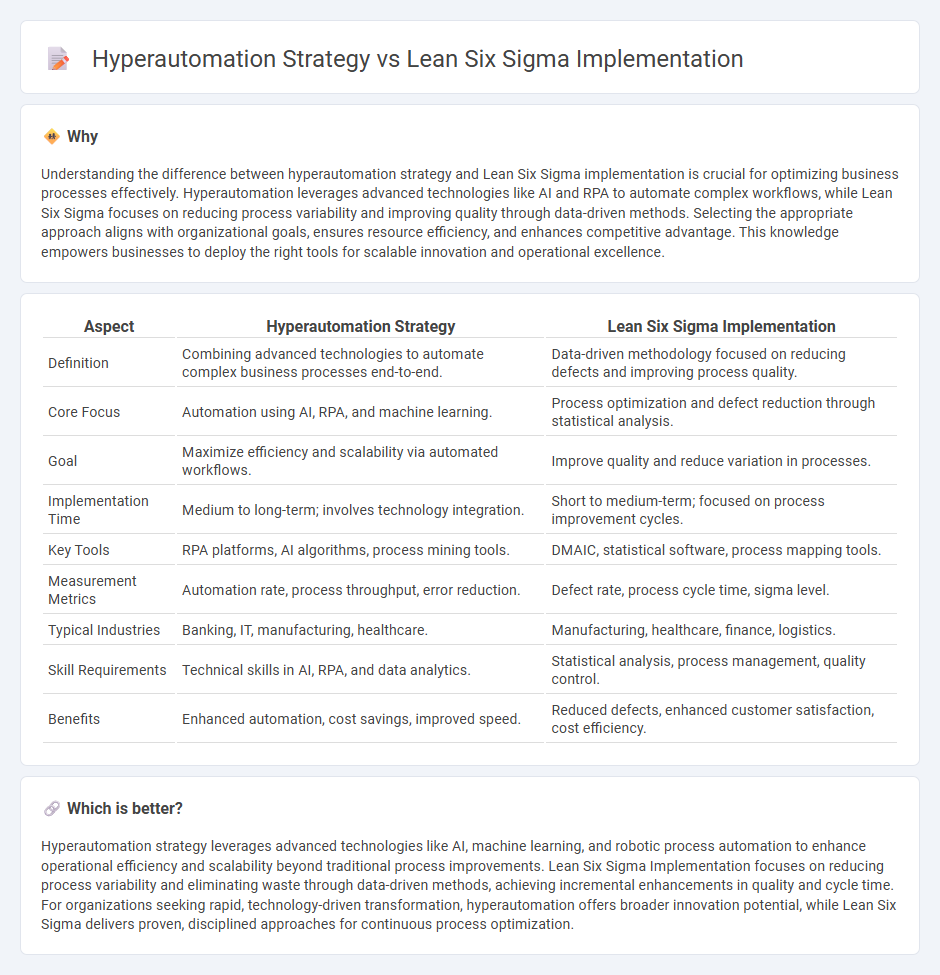

Understanding the difference between hyperautomation strategy and Lean Six Sigma implementation is crucial for optimizing business processes effectively. Hyperautomation leverages advanced technologies like AI and RPA to automate complex workflows, while Lean Six Sigma focuses on reducing process variability and improving quality through data-driven methods. Selecting the appropriate approach aligns with organizational goals, ensures resource efficiency, and enhances competitive advantage. This knowledge empowers businesses to deploy the right tools for scalable innovation and operational excellence.

Comparison Table

| Aspect | Hyperautomation Strategy | Lean Six Sigma Implementation |

|---|---|---|

| Definition | Combining advanced technologies to automate complex business processes end-to-end. | Data-driven methodology focused on reducing defects and improving process quality. |

| Core Focus | Automation using AI, RPA, and machine learning. | Process optimization and defect reduction through statistical analysis. |

| Goal | Maximize efficiency and scalability via automated workflows. | Improve quality and reduce variation in processes. |

| Implementation Time | Medium to long-term; involves technology integration. | Short to medium-term; focused on process improvement cycles. |

| Key Tools | RPA platforms, AI algorithms, process mining tools. | DMAIC, statistical software, process mapping tools. |

| Measurement Metrics | Automation rate, process throughput, error reduction. | Defect rate, process cycle time, sigma level. |

| Typical Industries | Banking, IT, manufacturing, healthcare. | Manufacturing, healthcare, finance, logistics. |

| Skill Requirements | Technical skills in AI, RPA, and data analytics. | Statistical analysis, process management, quality control. |

| Benefits | Enhanced automation, cost savings, improved speed. | Reduced defects, enhanced customer satisfaction, cost efficiency. |

Which is better?

Hyperautomation strategy leverages advanced technologies like AI, machine learning, and robotic process automation to enhance operational efficiency and scalability beyond traditional process improvements. Lean Six Sigma Implementation focuses on reducing process variability and eliminating waste through data-driven methods, achieving incremental enhancements in quality and cycle time. For organizations seeking rapid, technology-driven transformation, hyperautomation offers broader innovation potential, while Lean Six Sigma delivers proven, disciplined approaches for continuous process optimization.

Connection

Hyperautomation strategy and Lean Six Sigma implementation are connected through their shared focus on process optimization and efficiency enhancement. Lean Six Sigma utilizes data-driven methodologies to identify and eliminate waste, while hyperautomation leverages advanced technologies like AI, RPA, and machine learning to automate those optimized processes. Integrating these approaches accelerates digital transformation and drives continuous improvement in consulting projects.

Key Terms

Process Improvement

Lean Six Sigma implementation targets process improvement by utilizing data-driven methods to eliminate waste and reduce variability, enhancing operational efficiency. Hyperautomation strategy integrates advanced technologies such as AI, machine learning, and robotic process automation (RPA) to automate complex workflows and optimize end-to-end processes across the enterprise. Explore how combining these approaches can maximize process improvement outcomes.

Automation Technologies

Lean Six Sigma implementation emphasizes process improvement by reducing waste and variation through data-driven methodologies, leveraging automation technologies such as robotic process automation (RPA) and workflow automation to streamline repetitive tasks. Hyperautomation strategy expands on this by integrating advanced tools including artificial intelligence (AI), machine learning (ML), and intelligent process automation (IPA) to automate complex decision-making and end-to-end business processes. Explore the latest developments in automation technologies to understand how these approaches can transform operational efficiency.

Change Management

Lean Six Sigma implementation emphasizes structured process improvement through data-driven methodologies and employee engagement to reduce variability and enhance quality. Hyperautomation strategy leverages advanced technologies like AI, machine learning, and robotic process automation to accelerate digital transformation and optimize end-to-end workflows. Explore how integrating these approaches with effective change management can maximize organizational agility and operational efficiency.

Source and External Links

What Is Lean Six Sigma? How to Apply It in Your Organization - Lean Six Sigma implementation follows five main steps: Define the problem, Measure the problem quantitatively, Analyze the root cause, Improve by removing inefficiencies, and Control to sustain the gains.

What Are the 7 Steps To Successful Lean Six Sigma Implementation? - The seven key steps to implement Lean Six Sigma are: gain strategic management support, raise awareness, establish ownership, define value, set baselines, implement improvements, and sustain continuous improvement.

Eight Steps to a Successful Lean Six Sigma Implementation - Successful deployment involves creating urgency, securing resources, teaching methodology, prioritizing activities aligned to business goals, establishing ownership, and recognizing contributions for sustained implementation.

dowidth.com

dowidth.com