Operational excellence mapping focuses on systematically analyzing business processes to enhance efficiency, quality, and performance by identifying key operational drivers and metrics. Heat mapping visually represents data intensity or risk levels across processes to pinpoint critical areas requiring attention, enabling quick prioritization in problem-solving. Explore more to understand how these methodologies complement each other in driving continuous improvement and strategic decision-making.

Why it is important

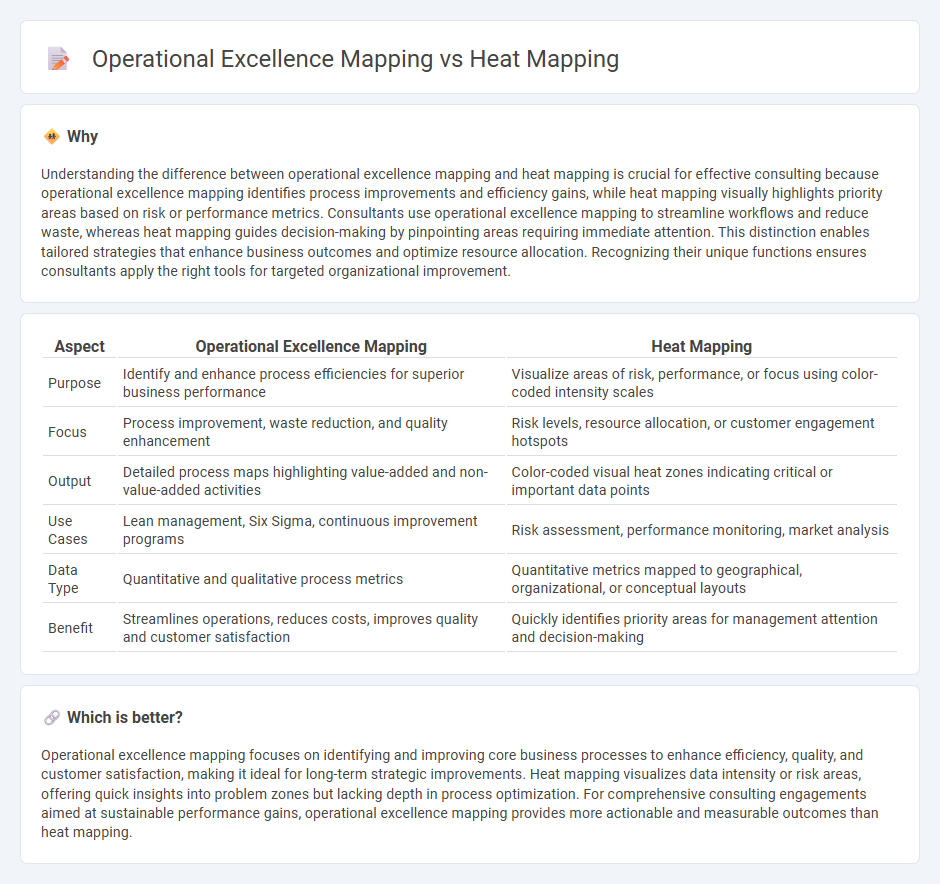

Understanding the difference between operational excellence mapping and heat mapping is crucial for effective consulting because operational excellence mapping identifies process improvements and efficiency gains, while heat mapping visually highlights priority areas based on risk or performance metrics. Consultants use operational excellence mapping to streamline workflows and reduce waste, whereas heat mapping guides decision-making by pinpointing areas requiring immediate attention. This distinction enables tailored strategies that enhance business outcomes and optimize resource allocation. Recognizing their unique functions ensures consultants apply the right tools for targeted organizational improvement.

Comparison Table

| Aspect | Operational Excellence Mapping | Heat Mapping |

|---|---|---|

| Purpose | Identify and enhance process efficiencies for superior business performance | Visualize areas of risk, performance, or focus using color-coded intensity scales |

| Focus | Process improvement, waste reduction, and quality enhancement | Risk levels, resource allocation, or customer engagement hotspots |

| Output | Detailed process maps highlighting value-added and non-value-added activities | Color-coded visual heat zones indicating critical or important data points |

| Use Cases | Lean management, Six Sigma, continuous improvement programs | Risk assessment, performance monitoring, market analysis |

| Data Type | Quantitative and qualitative process metrics | Quantitative metrics mapped to geographical, organizational, or conceptual layouts |

| Benefit | Streamlines operations, reduces costs, improves quality and customer satisfaction | Quickly identifies priority areas for management attention and decision-making |

Which is better?

Operational excellence mapping focuses on identifying and improving core business processes to enhance efficiency, quality, and customer satisfaction, making it ideal for long-term strategic improvements. Heat mapping visualizes data intensity or risk areas, offering quick insights into problem zones but lacking depth in process optimization. For comprehensive consulting engagements aimed at sustainable performance gains, operational excellence mapping provides more actionable and measurable outcomes than heat mapping.

Connection

Operational excellence mapping identifies key processes and performance indicators crucial for enhancing organizational efficiency. Heat mapping visually represents these areas, highlighting strengths and weaknesses to prioritize improvement efforts effectively. Integrating both tools enables consultants to target high-impact operational gaps and drive strategic decision-making.

Key Terms

Data Visualization

Heat mapping provides a visual representation of data intensity through color gradations, facilitating quick identification of hotspots in processes or performance areas. Operational excellence mapping integrates heat maps within broader frameworks to analyze workflows, pinpoint inefficiencies, and drive continuous improvement initiatives. Explore detailed methodologies to leverage data visualization for enhancing operational efficiency and informed decision-making.

Process Optimization

Heat mapping visualizes process inefficiencies by highlighting key performance metrics such as bottlenecks and cycle times, enabling targeted improvements in operational workflows. Operational excellence mapping integrates strategic frameworks with real-time data to optimize processes, reduce waste, and enhance overall productivity systematically. Explore detailed approaches to effectively implement these mapping techniques for superior process optimization outcomes.

Performance Metrics

Heat mapping visually highlights performance metrics by illustrating areas of high and low activity or risk, enabling quick identification of critical operational issues. Operational excellence mapping integrates performance metrics into a broader framework aimed at continuous improvement, process optimization, and strategic alignment within the organization. Explore detailed analyses and comparisons to understand how each approach enhances operational effectiveness.

Source and External Links

What is a heat map (heatmap)? | Definition from TechTarget - A heat map is a two-dimensional data visualization that uses color gradients to represent different values, allowing immediate visual identification of patterns or relationships in the data.

Heat map - Heat maps are categorized into spatial (geographic) and grid (matrix-based) types, with color intensity reflecting the magnitude of values, and are widely used for displaying complex data sets in an intuitive format.

Heatmapper - Heatmapper is a web-based tool for creating, customizing, and exploring various types of heat maps, including gene expression, correlation, and geographic data visualizations, with interactive features for data exploration.

dowidth.com

dowidth.com