Product Information Management (PIM) centralizes and organizes detailed product data to ensure consistency across sales channels, enhancing customer experience and marketing accuracy. Warehouse Management Systems (WMS) optimize inventory control, storage efficiency, and order fulfillment within physical warehouses to streamline logistics operations. Explore how integrating PIM and WMS can drive comprehensive commerce efficiency and boost business performance.

Why it is important

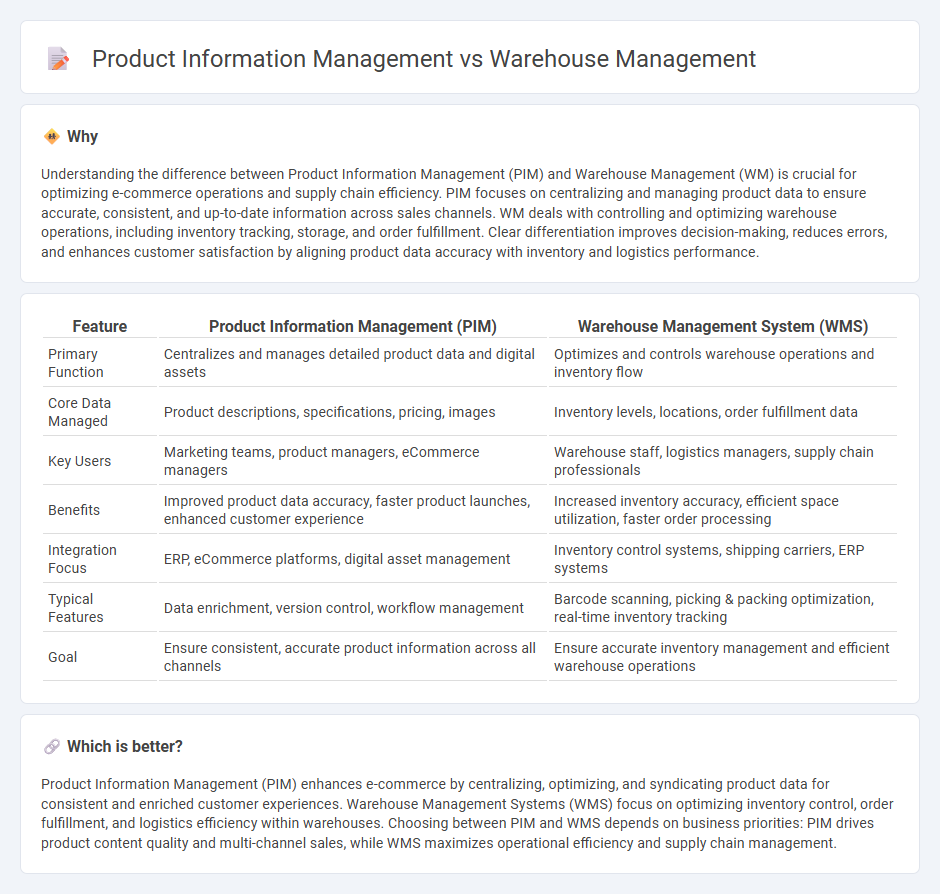

Understanding the difference between Product Information Management (PIM) and Warehouse Management (WM) is crucial for optimizing e-commerce operations and supply chain efficiency. PIM focuses on centralizing and managing product data to ensure accurate, consistent, and up-to-date information across sales channels. WM deals with controlling and optimizing warehouse operations, including inventory tracking, storage, and order fulfillment. Clear differentiation improves decision-making, reduces errors, and enhances customer satisfaction by aligning product data accuracy with inventory and logistics performance.

Comparison Table

| Feature | Product Information Management (PIM) | Warehouse Management System (WMS) |

|---|---|---|

| Primary Function | Centralizes and manages detailed product data and digital assets | Optimizes and controls warehouse operations and inventory flow |

| Core Data Managed | Product descriptions, specifications, pricing, images | Inventory levels, locations, order fulfillment data |

| Key Users | Marketing teams, product managers, eCommerce managers | Warehouse staff, logistics managers, supply chain professionals |

| Benefits | Improved product data accuracy, faster product launches, enhanced customer experience | Increased inventory accuracy, efficient space utilization, faster order processing |

| Integration Focus | ERP, eCommerce platforms, digital asset management | Inventory control systems, shipping carriers, ERP systems |

| Typical Features | Data enrichment, version control, workflow management | Barcode scanning, picking & packing optimization, real-time inventory tracking |

| Goal | Ensure consistent, accurate product information across all channels | Ensure accurate inventory management and efficient warehouse operations |

Which is better?

Product Information Management (PIM) enhances e-commerce by centralizing, optimizing, and syndicating product data for consistent and enriched customer experiences. Warehouse Management Systems (WMS) focus on optimizing inventory control, order fulfillment, and logistics efficiency within warehouses. Choosing between PIM and WMS depends on business priorities: PIM drives product content quality and multi-channel sales, while WMS maximizes operational efficiency and supply chain management.

Connection

Product information management (PIM) centralizes and enriches product data, ensuring accuracy and consistency across all sales channels, while warehouse management systems (WMS) optimize inventory storage, order fulfillment, and logistics. The integration of PIM with WMS enhances real-time visibility of stock levels, streamlines demand forecasting, and reduces errors in order processing. This connection improves operational efficiency, leading to faster delivery times and increased customer satisfaction in commerce.

Key Terms

Warehouse management:

Warehouse management centers on optimizing inventory storage, tracking stock levels, and streamlining order fulfillment processes to enhance operational efficiency and reduce costs. It leverages technology such as Warehouse Management Systems (WMS) to automate tasks, improve accuracy, and facilitate real-time data visibility. Explore advanced warehouse management strategies and tools to maximize productivity and ensure seamless supply chain execution.

Inventory Control

Warehouse management systems (WMS) optimize inventory control by tracking stock levels, locations, and movement within storage facilities, ensuring real-time visibility and accuracy. Product Information Management (PIM) centralizes product data, enhancing data consistency and accuracy but does not manage physical inventory flow. Explore the differences between WMS and PIM to improve your inventory control strategy effectively.

Order Fulfillment

Warehouse management systems (WMS) optimize the storage, picking, and shipping processes to ensure accurate and timely order fulfillment, reducing errors and operational costs. Product information management (PIM) focuses on centralizing and maintaining accurate product data, enhancing order accuracy by providing consistent item details across sales channels. Explore the differences between WMS and PIM to improve your order fulfillment strategy.

Source and External Links

What is Warehouse Management? Benefits, Processes & Strategies - Warehouse management involves six core processes--receiving, put-away, storage, picking, packing, and shipping--which must be optimized together to maintain efficient warehouse operations.

What is Warehouse Management? Processes, Performance ... - Key principles of warehouse management include maintaining optimal stock levels, organizing material handling and storage, processing orders quickly, and linking warehouse management to sales order processing to enhance overall supply chain performance.

Warehouse Management: A Complete Guide (2025) - Hopstack - Effective warehouse management requires process optimization, real-time performance analytics, and monitoring labor productivity to meet customer demands and improve operational efficiency across inbound and outbound activities.

dowidth.com

dowidth.com