Product Information Management (PIM) systems centralize and organize product data to ensure consistency, accuracy, and seamless distribution across sales channels. Supplier Relationship Management (SRM) focuses on optimizing interactions and collaboration with suppliers to enhance procurement efficiency and supply chain reliability. Explore the key differences and benefits of PIM and SRM to improve your commerce strategies.

Why it is important

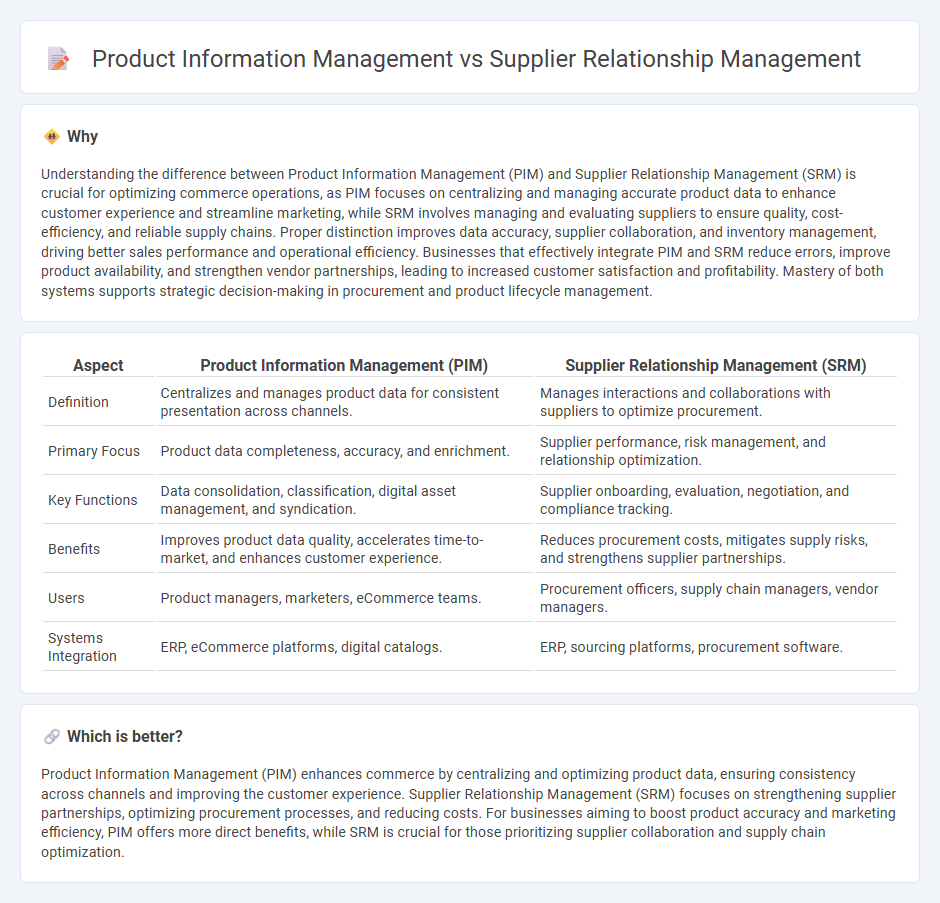

Understanding the difference between Product Information Management (PIM) and Supplier Relationship Management (SRM) is crucial for optimizing commerce operations, as PIM focuses on centralizing and managing accurate product data to enhance customer experience and streamline marketing, while SRM involves managing and evaluating suppliers to ensure quality, cost-efficiency, and reliable supply chains. Proper distinction improves data accuracy, supplier collaboration, and inventory management, driving better sales performance and operational efficiency. Businesses that effectively integrate PIM and SRM reduce errors, improve product availability, and strengthen vendor partnerships, leading to increased customer satisfaction and profitability. Mastery of both systems supports strategic decision-making in procurement and product lifecycle management.

Comparison Table

| Aspect | Product Information Management (PIM) | Supplier Relationship Management (SRM) |

|---|---|---|

| Definition | Centralizes and manages product data for consistent presentation across channels. | Manages interactions and collaborations with suppliers to optimize procurement. |

| Primary Focus | Product data completeness, accuracy, and enrichment. | Supplier performance, risk management, and relationship optimization. |

| Key Functions | Data consolidation, classification, digital asset management, and syndication. | Supplier onboarding, evaluation, negotiation, and compliance tracking. |

| Benefits | Improves product data quality, accelerates time-to-market, and enhances customer experience. | Reduces procurement costs, mitigates supply risks, and strengthens supplier partnerships. |

| Users | Product managers, marketers, eCommerce teams. | Procurement officers, supply chain managers, vendor managers. |

| Systems Integration | ERP, eCommerce platforms, digital catalogs. | ERP, sourcing platforms, procurement software. |

Which is better?

Product Information Management (PIM) enhances commerce by centralizing and optimizing product data, ensuring consistency across channels and improving the customer experience. Supplier Relationship Management (SRM) focuses on strengthening supplier partnerships, optimizing procurement processes, and reducing costs. For businesses aiming to boost product accuracy and marketing efficiency, PIM offers more direct benefits, while SRM is crucial for those prioritizing supplier collaboration and supply chain optimization.

Connection

Product Information Management (PIM) centralizes accurate and consistent product data, enhancing supplier collaboration by ensuring all parties access up-to-date product specifications and inventory levels. Supplier Relationship Management (SRM) leverages this streamlined data flow to optimize procurement processes, negotiate better terms, and improve supply chain reliability. Integration of PIM and SRM drives operational efficiency, reduces errors, and accelerates time-to-market in commerce.

Key Terms

Supplier relationship management:

Supplier relationship management (SRM) focuses on optimizing interactions between a company and its suppliers to improve collaboration, ensure timely delivery, and reduce procurement costs. It involves strategic sourcing, supplier performance evaluation, and risk management to maintain supply chain efficiency. Discover how effective SRM can transform your procurement process and enhance business value.

Procurement

Supplier relationship management (SRM) optimizes procurement by enhancing collaboration, risk management, and performance tracking of suppliers, ensuring reliable and cost-effective supply chains. Product information management (PIM) centralizes and standardizes product data to improve accuracy, consistency, and efficiency in procurement decisions. Explore the differences to leverage SRM and PIM for a robust procurement strategy.

Contract negotiation

Supplier relationship management (SRM) centers on optimizing contract negotiation processes by fostering collaboration, enhancing communication channels, and ensuring compliance with agreed terms to build long-term partnerships. Product information management (PIM) focuses on organizing and standardizing product data, which indirectly supports contract negotiations by providing accurate, up-to-date product specifications and pricing details. Explore further to understand how integrating SRM and PIM can streamline contract negotiation and drive procurement efficiency.

Source and External Links

Supplier relationship management - Supplier relationship management (SRM) is an enterprise-wide process of assessing and coordinating supplier interactions across the relationship lifecycle to maximize value, focusing on developing mutually beneficial relationships with key suppliers for innovation and competitive advantage.

What is Supplier Relationship Management in Procurement? - SRM is a structured six-step process involving supplier identification/segmentation, success definition with KPIs, strategy development, supplier engagement, monitoring and evaluation, and continuous improvement to maintain effective supplier collaboration.

What is Supplier Relationship Management(SRM)? - Supplier relationship management focuses on building, managing, and nurturing business relationships with vendors to improve supply continuity, mitigate pricing risks, and enhance supplier performance through trust and communication.

dowidth.com

dowidth.com