A circular supply chain focuses on resource efficiency by recycling, refurbishing, and reusing materials to minimize waste and environmental impact. In contrast, a linear supply chain follows a traditional "take-make-dispose" model, often leading to increased resource depletion and landfill accumulation. Explore how businesses leverage circular supply chains to drive sustainability and profitability.

Why it is important

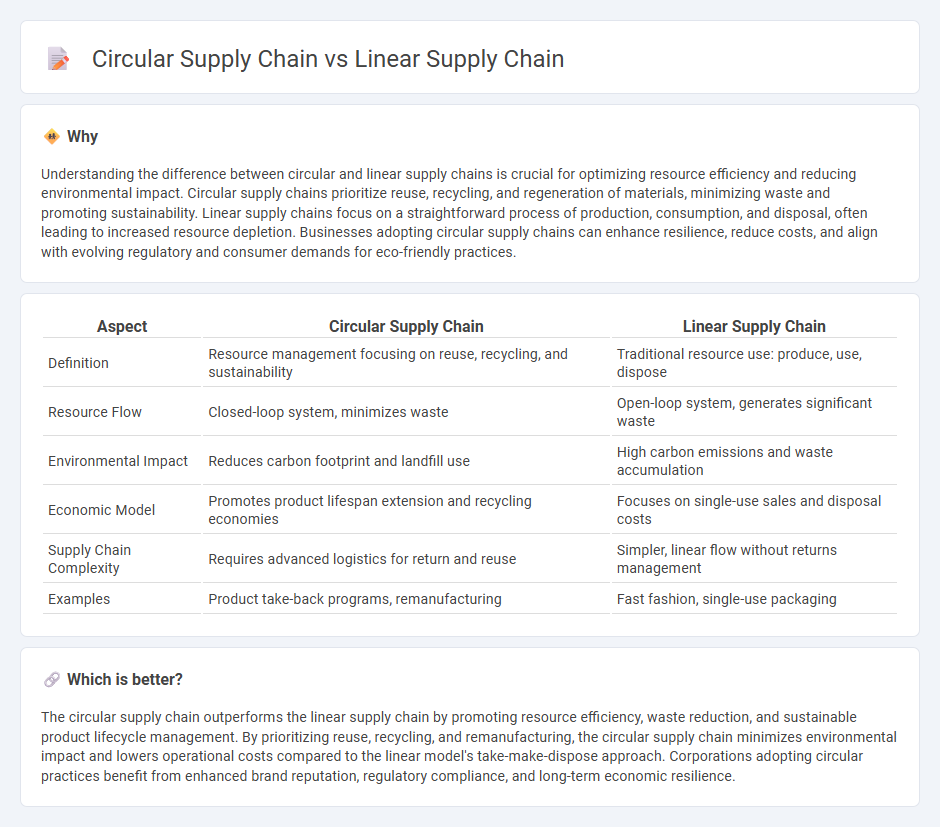

Understanding the difference between circular and linear supply chains is crucial for optimizing resource efficiency and reducing environmental impact. Circular supply chains prioritize reuse, recycling, and regeneration of materials, minimizing waste and promoting sustainability. Linear supply chains focus on a straightforward process of production, consumption, and disposal, often leading to increased resource depletion. Businesses adopting circular supply chains can enhance resilience, reduce costs, and align with evolving regulatory and consumer demands for eco-friendly practices.

Comparison Table

| Aspect | Circular Supply Chain | Linear Supply Chain |

|---|---|---|

| Definition | Resource management focusing on reuse, recycling, and sustainability | Traditional resource use: produce, use, dispose |

| Resource Flow | Closed-loop system, minimizes waste | Open-loop system, generates significant waste |

| Environmental Impact | Reduces carbon footprint and landfill use | High carbon emissions and waste accumulation |

| Economic Model | Promotes product lifespan extension and recycling economies | Focuses on single-use sales and disposal costs |

| Supply Chain Complexity | Requires advanced logistics for return and reuse | Simpler, linear flow without returns management |

| Examples | Product take-back programs, remanufacturing | Fast fashion, single-use packaging |

Which is better?

The circular supply chain outperforms the linear supply chain by promoting resource efficiency, waste reduction, and sustainable product lifecycle management. By prioritizing reuse, recycling, and remanufacturing, the circular supply chain minimizes environmental impact and lowers operational costs compared to the linear model's take-make-dispose approach. Corporations adopting circular practices benefit from enhanced brand reputation, regulatory compliance, and long-term economic resilience.

Connection

Circular supply chains and linear supply chains are connected through the flow of materials and products, where circular supply chains extend the lifecycle of resources by incorporating reuse, recycling, and remanufacturing processes into the traditionally linear flow of extraction, production, and disposal. The integration of circular principles reduces waste and environmental impact while maintaining the efficiency of the linear supply chain's operational structure. This connection enables businesses to optimize resource efficiency, improve sustainability, and enhance supply chain resilience.

Key Terms

Resource Flow

Linear supply chains follow a straightforward path where raw materials are extracted, transformed into products, and eventually discarded as waste, emphasizing a one-way resource flow. Circular supply chains prioritize resource efficiency by integrating processes like recycling, remanufacturing, and reuse to create a closed-loop system that minimizes waste and conserves materials. Explore the advantages and implementation strategies of circular supply chains to enhance sustainability and operational resilience.

Waste Management

Linear supply chains follow a traditional, step-by-step process from raw material extraction to product disposal, generating significant waste at the end of the product lifecycle. Circular supply chains prioritize waste reduction by incorporating recycling, reusing, and refurbishing materials to create a closed-loop system that minimizes environmental impact. Explore the benefits and strategies of circular supply chains to optimize waste management and sustainability.

Product Lifecycle

Linear supply chains follow a straightforward progression from raw material extraction to product manufacturing, distribution, use, and disposal, leading to significant waste and resource depletion over the product lifecycle. Circular supply chains emphasize resource regeneration by designing products for reuse, refurbishment, remanufacturing, and recycling, thereby extending the product lifecycle and minimizing environmental impact. Discover how transitioning to circular supply chains optimizes sustainability and enhances resource efficiency throughout the product lifecycle.

Source and External Links

More Supply Chains have Moved Away from Traditional Linear Models in 2021 - A linear supply chain functions as a one-way process where materials move from raw input to product to disposal, but disruptions in this model can cause catastrophic effects; newer models like network and circular supply chains are more resilient, efficient, and environmentally friendly alternatives.

Linear vs. Circular Supply Chains - UNEX Blog - The linear supply chain model follows a "Take, Make, Dispose" pattern that is increasingly unsustainable due to environmental impact, cost volatility, and waste accumulation, driving businesses to seek circular and more sustainable supply chain strategies.

Supply chains and the circular economy - Ellen MacArthur Foundation - Traditional linear supply chains are based on resource extraction, production, and waste, but a circular economy approach redesigns supply chains into distributed, interconnected networks with multidirectional flows, circular inputs, and processes that improve resilience, reduce costs, and lessen environmental harm.

dowidth.com

dowidth.com