On-demand warehousing offers flexible, short-term storage solutions that scale with fluctuating inventory needs, unlike consignment warehousing, which involves long-term agreements where goods remain owned by the supplier until sold. This flexibility reduces overhead costs and improves supply chain responsiveness, making it suitable for businesses facing unpredictable demand. Explore the benefits and strategic implications of both warehousing models to optimize your commerce operations.

Why it is important

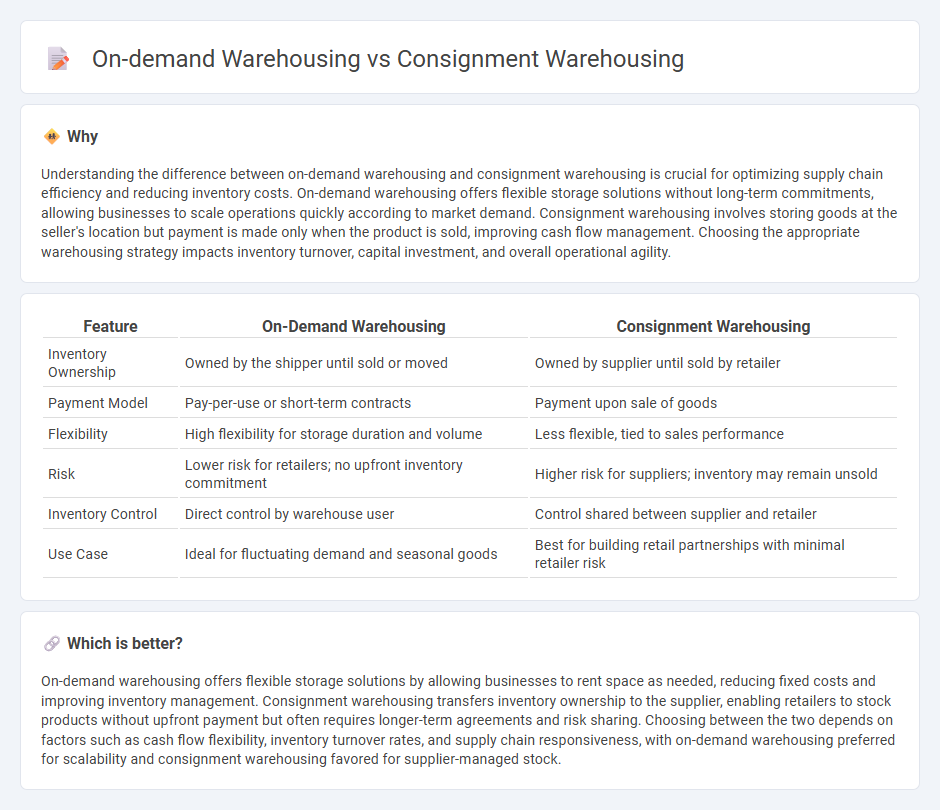

Understanding the difference between on-demand warehousing and consignment warehousing is crucial for optimizing supply chain efficiency and reducing inventory costs. On-demand warehousing offers flexible storage solutions without long-term commitments, allowing businesses to scale operations quickly according to market demand. Consignment warehousing involves storing goods at the seller's location but payment is made only when the product is sold, improving cash flow management. Choosing the appropriate warehousing strategy impacts inventory turnover, capital investment, and overall operational agility.

Comparison Table

| Feature | On-Demand Warehousing | Consignment Warehousing |

|---|---|---|

| Inventory Ownership | Owned by the shipper until sold or moved | Owned by supplier until sold by retailer |

| Payment Model | Pay-per-use or short-term contracts | Payment upon sale of goods |

| Flexibility | High flexibility for storage duration and volume | Less flexible, tied to sales performance |

| Risk | Lower risk for retailers; no upfront inventory commitment | Higher risk for suppliers; inventory may remain unsold |

| Inventory Control | Direct control by warehouse user | Control shared between supplier and retailer |

| Use Case | Ideal for fluctuating demand and seasonal goods | Best for building retail partnerships with minimal retailer risk |

Which is better?

On-demand warehousing offers flexible storage solutions by allowing businesses to rent space as needed, reducing fixed costs and improving inventory management. Consignment warehousing transfers inventory ownership to the supplier, enabling retailers to stock products without upfront payment but often requires longer-term agreements and risk sharing. Choosing between the two depends on factors such as cash flow flexibility, inventory turnover rates, and supply chain responsiveness, with on-demand warehousing preferred for scalability and consignment warehousing favored for supplier-managed stock.

Connection

On-demand warehousing and consignment warehousing both enhance supply chain flexibility by optimizing inventory storage and management. On-demand warehousing allows businesses to scale storage space dynamically, while consignment warehousing enables suppliers to store goods at a retailer's location, transferring inventory ownership only upon sale. Combining these models improves inventory turnover rates, reduces holding costs, and boosts supply chain responsiveness.

Key Terms

Inventory Management

Consignment warehousing allows suppliers to store inventory at the buyer's location, improving stock availability while reducing holding costs and risk of overstocking. On-demand warehousing offers flexible, short-term storage solutions that optimize inventory turnover and respond quickly to market fluctuations. Explore in-depth comparisons of inventory management benefits and challenges to determine the best strategy for your supply chain needs.

Flexibility

Consignment warehousing offers limited flexibility due to fixed inventory levels stored at a retailer's location, often requiring long-term agreements and upfront inventory commitments. On-demand warehousing provides dynamic flexibility by allowing businesses to scale storage space in real-time, pay only for what they use, and adjust inventory based on fluctuating demand. Explore the benefits of these warehousing solutions to optimize your supply chain management.

Cost Structure

Consignment warehousing typically involves fixed costs such as long-term storage fees and inventory holding expenses, making it more suitable for businesses with consistent, predictable demand. On-demand warehousing offers variable costs based on actual usage, which can significantly reduce expenses during periods of low inventory turnover or fluctuating demand. Explore detailed cost comparisons and strategic applications to optimize your warehousing budget effectively.

Source and External Links

What is a consignment warehouse? Definition with examples - A consignment warehouse is a storage arrangement where goods are kept by the retailer or a third party but remain the supplier's property until sold, allowing payment only when goods are taken, thus minimizing inventory investment and enhancing supply chain efficiency.

Consignment Warehouse - Symestic - This type of warehouse allows retailers to store supplier-owned goods and pay only after sales, reducing financial risk and improving liquidity and flexibility in inventory management.

Consignment Warehouse Definition and Meaning - Buske Logistics - A consignment warehouse enables businesses to store goods without upfront payment, reducing the risk of unsold inventory, saving costs, and facilitating market entry with less initial investment.

dowidth.com

dowidth.com