Micro fulfillment centers enable faster order processing by strategically locating small warehouses closer to urban customers, reducing last-mile delivery times and enhancing customer satisfaction. Centralized fulfillment centers, on the other hand, operate large-scale warehouses that consolidate inventory in a single location, optimizing storage costs and streamlining inventory management. Discover how these models impact e-commerce efficiency and customer experience.

Why it is important

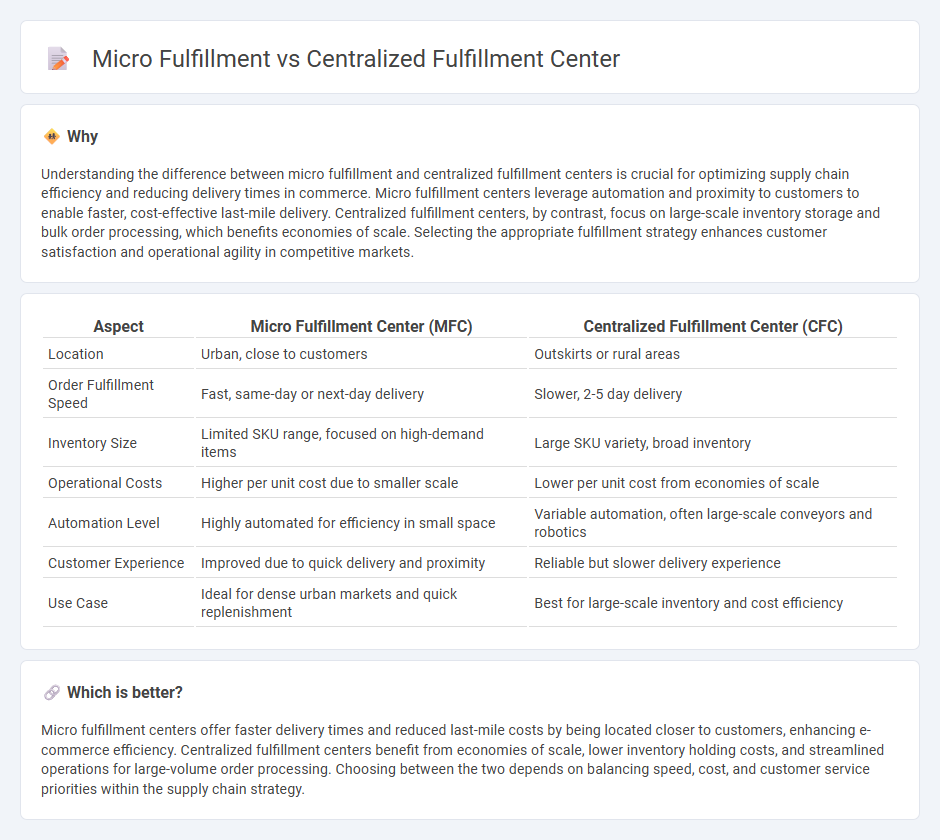

Understanding the difference between micro fulfillment and centralized fulfillment centers is crucial for optimizing supply chain efficiency and reducing delivery times in commerce. Micro fulfillment centers leverage automation and proximity to customers to enable faster, cost-effective last-mile delivery. Centralized fulfillment centers, by contrast, focus on large-scale inventory storage and bulk order processing, which benefits economies of scale. Selecting the appropriate fulfillment strategy enhances customer satisfaction and operational agility in competitive markets.

Comparison Table

| Aspect | Micro Fulfillment Center (MFC) | Centralized Fulfillment Center (CFC) |

|---|---|---|

| Location | Urban, close to customers | Outskirts or rural areas |

| Order Fulfillment Speed | Fast, same-day or next-day delivery | Slower, 2-5 day delivery |

| Inventory Size | Limited SKU range, focused on high-demand items | Large SKU variety, broad inventory |

| Operational Costs | Higher per unit cost due to smaller scale | Lower per unit cost from economies of scale |

| Automation Level | Highly automated for efficiency in small space | Variable automation, often large-scale conveyors and robotics |

| Customer Experience | Improved due to quick delivery and proximity | Reliable but slower delivery experience |

| Use Case | Ideal for dense urban markets and quick replenishment | Best for large-scale inventory and cost efficiency |

Which is better?

Micro fulfillment centers offer faster delivery times and reduced last-mile costs by being located closer to customers, enhancing e-commerce efficiency. Centralized fulfillment centers benefit from economies of scale, lower inventory holding costs, and streamlined operations for large-volume order processing. Choosing between the two depends on balancing speed, cost, and customer service priorities within the supply chain strategy.

Connection

Micro fulfillment centers are strategically located near urban areas to enable rapid order processing and local delivery, while centralized fulfillment centers manage bulk inventory and long-term storage. Both systems work together by transferring products from centralized hubs to micro fulfillment centers, optimizing supply chain efficiency and reducing delivery times. This integrated approach supports e-commerce scalability and enhances customer satisfaction through faster, more reliable order fulfillment.

Key Terms

Inventory Management

Centralized fulfillment centers consolidate inventory in a single location, optimizing stock management through bulk storage and streamlined replenishment processes, which reduces overhead but may increase delivery lead times. Micro fulfillment centers distribute smaller inventory quantities across multiple urban or local sites, enhancing speed and flexibility by enabling rapid order processing and last-mile delivery while requiring sophisticated inventory tracking systems. Explore how choosing the right inventory management approach can transform your fulfillment strategy.

Order Proximity

Centralized fulfillment centers consolidate inventory in a single location, optimizing large-scale storage but often increasing delivery distances, which can delay order fulfillment. Micro-fulfillment centers, strategically located near urban hubs, prioritize order proximity by enabling faster last-mile delivery and enhancing customer satisfaction through reduced transit times. Explore how leveraging order proximity impacts logistics efficiency and customer experience.

Scalability

Centralized fulfillment centers offer high scalability by consolidating inventory and streamlining bulk order processing, supporting rapid expansion for large retailers. Micro fulfillment centers enhance scalability through proximity to customers, enabling faster deliveries and flexible inventory management in urban areas. Explore more to understand which fulfillment model best suits your business scalability needs.

Source and External Links

Central Dist. Center: Logistics Guide | Fulfill.com Glossary - A centralized fulfillment center is a facility where goods are received from suppliers, stored, and then shipped to customers or retail outlets, performing key functions like inventory management, order processing, and shipping to ensure smooth eCommerce operations.

Importance Of Centralized Fulfillment Centers For E-commerce - Centralized fulfillment centers consolidate inventory from various sources into one location, allowing businesses to optimize their storage and distribution efficiently.

Regional vs. Centralized Distribution: Evaluating Approaches for ... - Centralized distribution involves consolidating distribution activities within a single hub, which enables economies of scale, streamlined logistics, and reduced per-unit handling costs for large-volume shipping across wide geographical areas.

dowidth.com

dowidth.com