Micro fulfillment centers focus on rapid order processing near urban areas by utilizing small-scale automation and robotics to handle last-mile deliveries efficiently. Automated warehouses employ large-scale robotic systems for inventory management and order fulfillment, optimizing space and reducing labor costs in centralized locations. Explore the differences between micro fulfillment and automated warehouses to enhance your supply chain strategy.

Why it is important

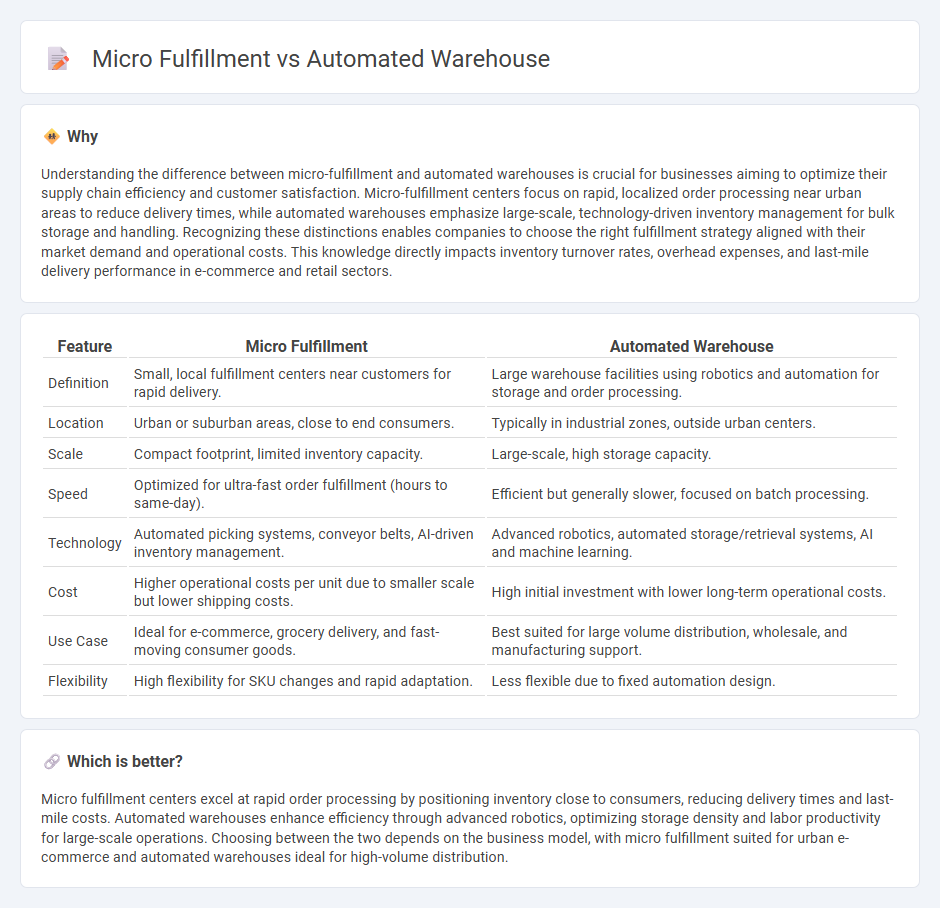

Understanding the difference between micro-fulfillment and automated warehouses is crucial for businesses aiming to optimize their supply chain efficiency and customer satisfaction. Micro-fulfillment centers focus on rapid, localized order processing near urban areas to reduce delivery times, while automated warehouses emphasize large-scale, technology-driven inventory management for bulk storage and handling. Recognizing these distinctions enables companies to choose the right fulfillment strategy aligned with their market demand and operational costs. This knowledge directly impacts inventory turnover rates, overhead expenses, and last-mile delivery performance in e-commerce and retail sectors.

Comparison Table

| Feature | Micro Fulfillment | Automated Warehouse |

|---|---|---|

| Definition | Small, local fulfillment centers near customers for rapid delivery. | Large warehouse facilities using robotics and automation for storage and order processing. |

| Location | Urban or suburban areas, close to end consumers. | Typically in industrial zones, outside urban centers. |

| Scale | Compact footprint, limited inventory capacity. | Large-scale, high storage capacity. |

| Speed | Optimized for ultra-fast order fulfillment (hours to same-day). | Efficient but generally slower, focused on batch processing. |

| Technology | Automated picking systems, conveyor belts, AI-driven inventory management. | Advanced robotics, automated storage/retrieval systems, AI and machine learning. |

| Cost | Higher operational costs per unit due to smaller scale but lower shipping costs. | High initial investment with lower long-term operational costs. |

| Use Case | Ideal for e-commerce, grocery delivery, and fast-moving consumer goods. | Best suited for large volume distribution, wholesale, and manufacturing support. |

| Flexibility | High flexibility for SKU changes and rapid adaptation. | Less flexible due to fixed automation design. |

Which is better?

Micro fulfillment centers excel at rapid order processing by positioning inventory close to consumers, reducing delivery times and last-mile costs. Automated warehouses enhance efficiency through advanced robotics, optimizing storage density and labor productivity for large-scale operations. Choosing between the two depends on the business model, with micro fulfillment suited for urban e-commerce and automated warehouses ideal for high-volume distribution.

Connection

Micro fulfillment centers utilize automated warehouse technologies such as robotics, conveyor systems, and AI-driven inventory management to expedite order processing in densely populated areas. These highly efficient automated warehouses reduce order fulfillment time and operational costs by streamlining storage and picking tasks within compact spaces. The integration of micro fulfillment with automation enhances e-commerce scalability, enabling retailers to meet increasing consumer demand for rapid delivery and accurate inventory management.

Key Terms

Robotics

Automated warehouses utilize robotics to manage large-scale inventory storage and retrieval efficiently, optimizing entire supply chain operations through high-capacity automated systems. Micro-fulfillment centers, powered by compact robotic solutions, focus on rapid order picking and processing in urban areas to meet growing e-commerce demand. Explore how robotics technology transforms warehousing strategies with enhanced speed and precision.

Order Picking

Automated warehouses utilize robotic systems and conveyor belts to streamline high-volume order picking, enhancing efficiency in large-scale distribution centers. Micro-fulfillment centers prioritize space optimization and rapid fulfillment for urban retail by employing compact automation solutions designed for small to mid-sized orders. Explore the latest advancements in automated order picking technologies and strategies to optimize your warehouse operations.

Last-Mile Delivery

Automated warehouses leverage robotics and high-density storage to streamline inventory management, reducing order processing times and minimizing human error. Micro fulfillment centers focus on proximity to urban consumers, employing compact automation to expedite last-mile delivery and meet growing demand for rapid order turnaround. Explore the benefits and differences of each to optimize your logistics strategy effectively.

Source and External Links

Automated Warehouses | Types and Benefits - AutoStore - Automated warehouses automate key logistics operations such as receiving, shipping, storage, and picking by using robots and warehouse management software to improve efficiency, reduce manual labor and errors, and enhance safety in the workplace.

Warehouse Automation | SSI SCHAEFER - Warehouse automation integrates hardware, software, and control systems like conveyor belts, robotics, and automated guided vehicles to streamline tasks such as inventory management and order fulfillment, aiming to increase productivity, accuracy, and space utilization.

Warehouse Automation Explained: Trends, Types & Best Practices - Warehouse automation ranges from basic mechanical aids like conveyors to advanced AI-driven robotics that autonomously navigate and manage warehouse tasks, with benefits including improved operational efficiency and minimized human error.

dowidth.com

dowidth.com